ENGLISH

OPERATION

CONSTRUCTIONCHARACTERISTICS

TECHNICALCHARACTERISTICS

HYDRAULIC CONNECTION (Fig.1)

ATTENTION.

ATTENTION.

ELECTRIC CONNECTION (fig. 2)

WARNING.

STARTING.

POSSIBLE PROBLEMS

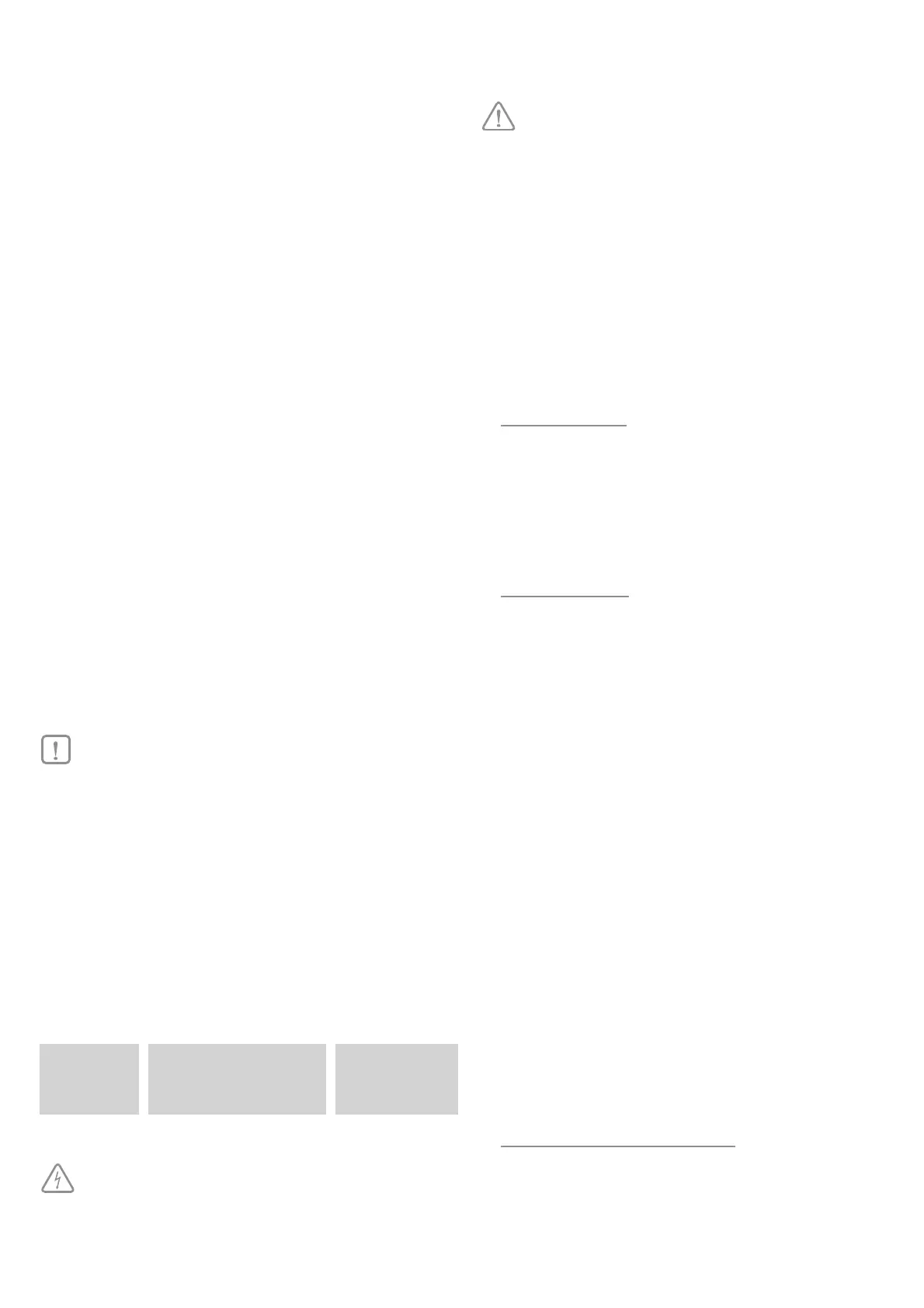

The OPTIMATIC controller orders the automatic start and stop of

the water pump when opening or closing any tap or valve of the

installation.When the water pump starts, it keeps running while it

exists any tap opened in the system, giving a constant flow an

pressure tothe network.

- Inlet male G 1'.’

- Outlet male G1'.'

- Special non return valve which avoids surges

- Security system avoiding the possibility for the machine to work

without water

- Pressure gauge

- Tension LED (POWER)

- Security systemLED (ALARM)

- Pump-working LED (ON)

- Manual startswitch(RESET)

- Integrated socket for motor connection according toCDIN-IEC

884-1.

- Cable with plugDIN 49 441 forconnection to theelectric supply.

- Tension: ~220/240 V

- Max. Intensity: 16(8)A

- Frequency: 50/60 Hz

- Protection: IP44

- Max. temperature of water: 60° C

- Max. Flow: 10.000 l/h

- Starting pressure: Type F15: 1,5 bar

Type F22: 2,2 bar

Type R:1,5 bar-2,5 bar

- Max. pressure for use: 10 bar

- Max. Pump power: 230V: 2HP(1500W)

Before proceeding with hydraulic connection it is essential to prime

the pump correctly. The electronic controller should be installed

always in horizontal position with the overmolded arrow pointing

to the top, connecting the inlet opening (male G1”) directly to the

pump and the outletopening (male G1” ) to the network.

Avoid oulet non return valves. The following

accessories are recommended: flexible with disassembling link for

network connection, protecting the set from possible flexion

charges and vibrations. Ball valves which allows the isolation of the

pump from the installation.

The water column between the pump and the

highest point of the installation depends on the starting pressure.

Here below, we give you a list with the height of the column and

the maximum pressure which must supplies the pump.

The adjustment of the starting pressure in type R is made by the

screwplaced in the back side of the device (fig.3)

Check the power supply to be ~220/240V. Connect the pump to

OPTIMATIC through the SCHUKO SOCKET. The OPTIMATIC can be

used with a single-phasepump with electrical input under 10 A.

Bad connections mayspoil the electroniccircuit.

H07RN-F 3G1 type cables (Ø8÷11mm) must be used in order to

ensureIP 44 protection.

1.-Be sure that the pump is primed, then slowly open a tap.

2.- Connect the electronic controller to the electric supply. The

tension LED will lit (POWER).

3.-The pump starts working automatically and within a

period of 20-25 seconds the pressure gauge will reach

approximately the maximum pressure provided by the pump.

During its working the corresponding LED (ON) will be on.

4.-Close the tap indicated on point 1. After 10-12 seconds the

pump will stop. The tension LED (POWER) will be the only one to

remainon.

Any problem after this procedure will be due to a defective pump

priming.

1.-

a) Water leak higher than 1,5 l/min. at some point:

Check the installation, taps, WC, etc.

b) Manual start switch (RESET) is blocked:

Act on it several times,in case the problem persists consult

your dealer.

c) Breakdown on the electronic card: proceed to its substitution.

d) Incorrect electric connection: check the connections

according to Fig.3.

2.-

a) Not enough water supply, the security system has been

activated and the LED (FAILURE) is on: check the water supply

and restartthe pump through the resetswitch(RESET).

b) The pump is not hydraulically primed. The safety system against

dry operation has been activated and the LED (FAILURE) is on: fill

with water the inlet, drain the water surplus in the installation

opening a faucet located to he same level of the pump - to

diminish the pressure of the water column over the flow sensor -

and restore the operationmode usingthe pushbutton RESET.

c) Pump is blocked: LED (FAILURE) is on, the security system is

activate: when we act on the manual start switch (RESET) the

LED (ON) is activatedbut the pump does not work:

Consult your dealer.

d) Failurein the electroniccircuit:

Switch off power supply, wait a few seconds and turn it on again.

If the pump does not start immediately then replacethe circuit.

e) Not electrical supply: check the proper electric feeding.The

tensionLED (POWER)should be on.

f) Not enough pump pressure:

The security system has been activated and the

corresponding LED (FAILURE) is on. Check that the pump

pressure is the one shown in the hydraulicconnection table.

g) Air in the pump aspiration: the pressure gauge will indicate a

pressure lower than the nominal or constant oscillations. The

security system will act by stopping the pump, the LED (FAILURE)

will be on.

Check the sealing of the connections and O-ring of the

aspiration conduct.

3.-

a) Small leak in some pointof theinstallation:

Verify possible tapor WC tankleaks and repairthem.

?

?

?

Pump does not stop:

Pump does not start:

The pump startsand stops repeatedly:

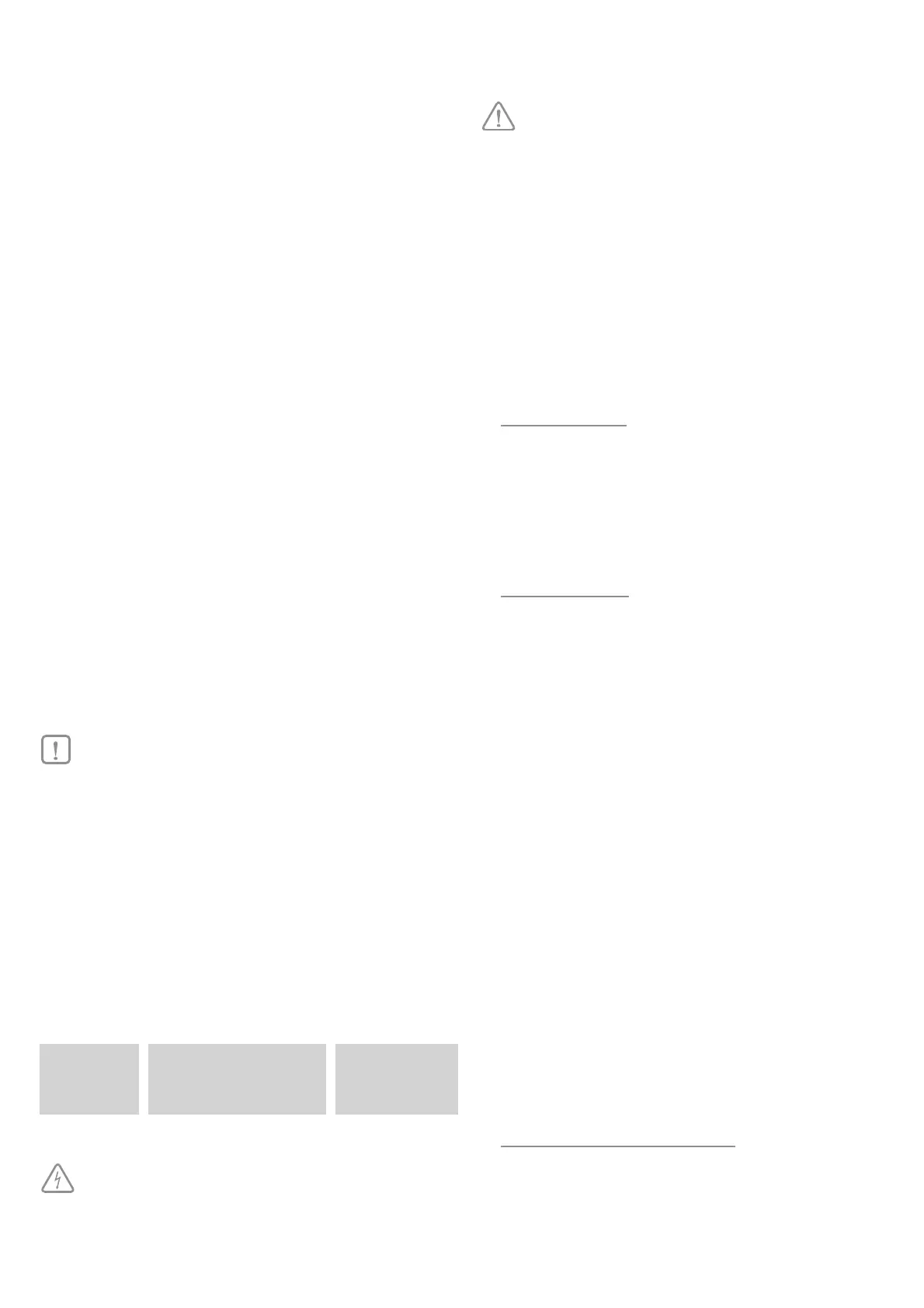

USING HEIGHT ADJUSTMENT PRESSURE MIN.PUMP PRESS

10m 1,2bar 1,7bar

15m 1,7bar 2,2bar

20m 2,2bar 2,7bar

Loading...

Loading...