200-2275

Revision B

Operator Manual

Manuel de l’opérateur

Manual del operador

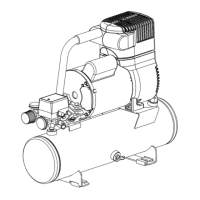

Oilless, Single Stage, Direct Drive, Electric Air Compressors

Sans l’huile, d’une seul étape, à prise directe, compresseurs d’air

électriques

Sin aciete, de una sola etapa, de mando directo, compresores de aire

eléctricos

Coleman Powermate, Inc. P.O. Box 206, 118 West Rock Street, Springfield MN 56087

Printed in U.S.A.

©

9-01

WARNING: Read and understand all safety precautions in this manual before operating. Failure to comply with

instructions in this manual could result in personal injury, property damage, and/or voiding of your warranty. Coleman

Powermate Compressors WILL NOT be liable for any damage because of failure to follow these instructions.

AVERTISSEMENT : Lisez et veillez à bien comprendre toutes les consignes de sécurité de ce manuel avant

d'utiliser l'appareil. Toute dérogation aux instructions contenues dans ce manuel peut entraîner l'annulation de la

garantie, causer des blessures et/ou des dégâts matériels. Le fabricant NE SAURA être tenu responsable de dommages

résultant de l'inobservation de ces instructions.

ADVERTENCIA: Lea y comprenda todas las precauciones de seguridad contenidas en este manual antes de

utilizar esta unidad. Si no cumple con las instrucciones de este manual podría ocasionar lesiones personales, daños a la

propiedad y/o la anulación de su garantía. El fabricante NO SERÁ responsable de ningún daño por no acatar estas

instrucciones.