IMPORTANT

The operation of a hydraulic circuit generally causes pollution due to impurities : loose

projections, paint, silica, sealing paste, rubber, resulting from the dismantling and assembly of

pipework and components.

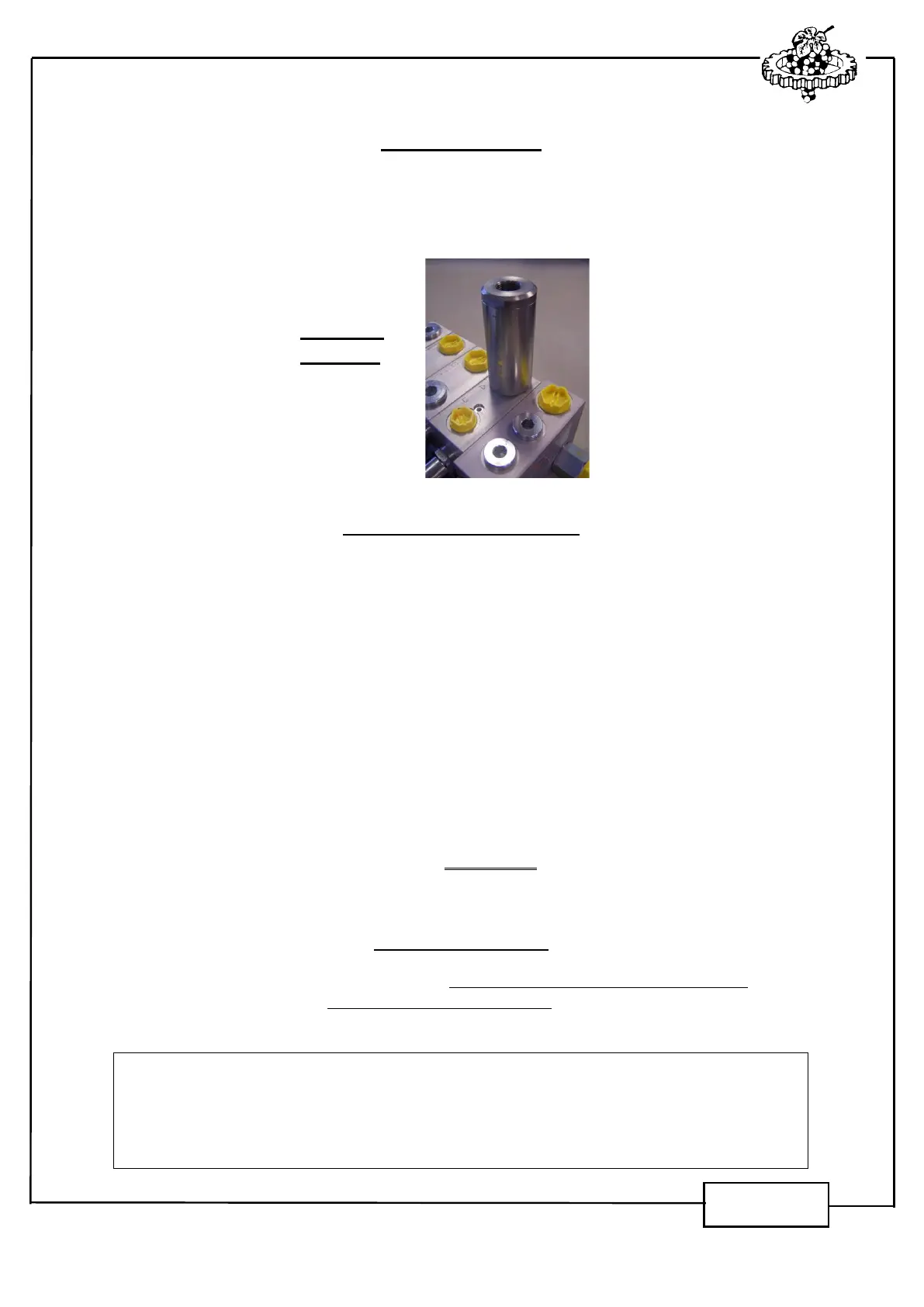

Filtering

element

Ref. 0502 6044

AT THE FIRST OPERATION

After one hour ½ of operation (corresponding to the running period), it is essential to

check the filter and to service it in order to eliminate pollution and to ensure that none remains

in suspension.

- PRIOR TO DISMANTLING : Clean the module and the area surrounding the

filter plug to avoid dirt entering the filter during servicing.

- Using an appropriate tool, disconnect the hose and remove the filtering element

from the hydraulic block.

- Remove the filtering element by unscrewing the top closing part.

- Soak the filtering element in a container of detergent : gasoline, diesel or benzene

for approximately 5 minutes to decompose particles loaded with oil.

- Blow compressed air through the porous element from the inside to the outside.

- Dry the filtering element.

- Reassemble the filtering element on the hydraulic system. Be carefull to each

joint. Screw the top closing part. Do not force. Clamping torque : 5 N.m.

- Reassemble the complete filter on the block and connect the hose.

SUBSEQUENT USE

Check the state of the porous element at least once during the trimming season. It is

vital that the unit be cleaned before the trimmer is put away (see the higher described

procedure).

IMPORTANT : In all cases, the filter element will be changed every 2 years for a normal

use, and every year in case of an intensive use.

In the event of shock or deterioration, the filter element will have to be

replaced.

Loading...

Loading...