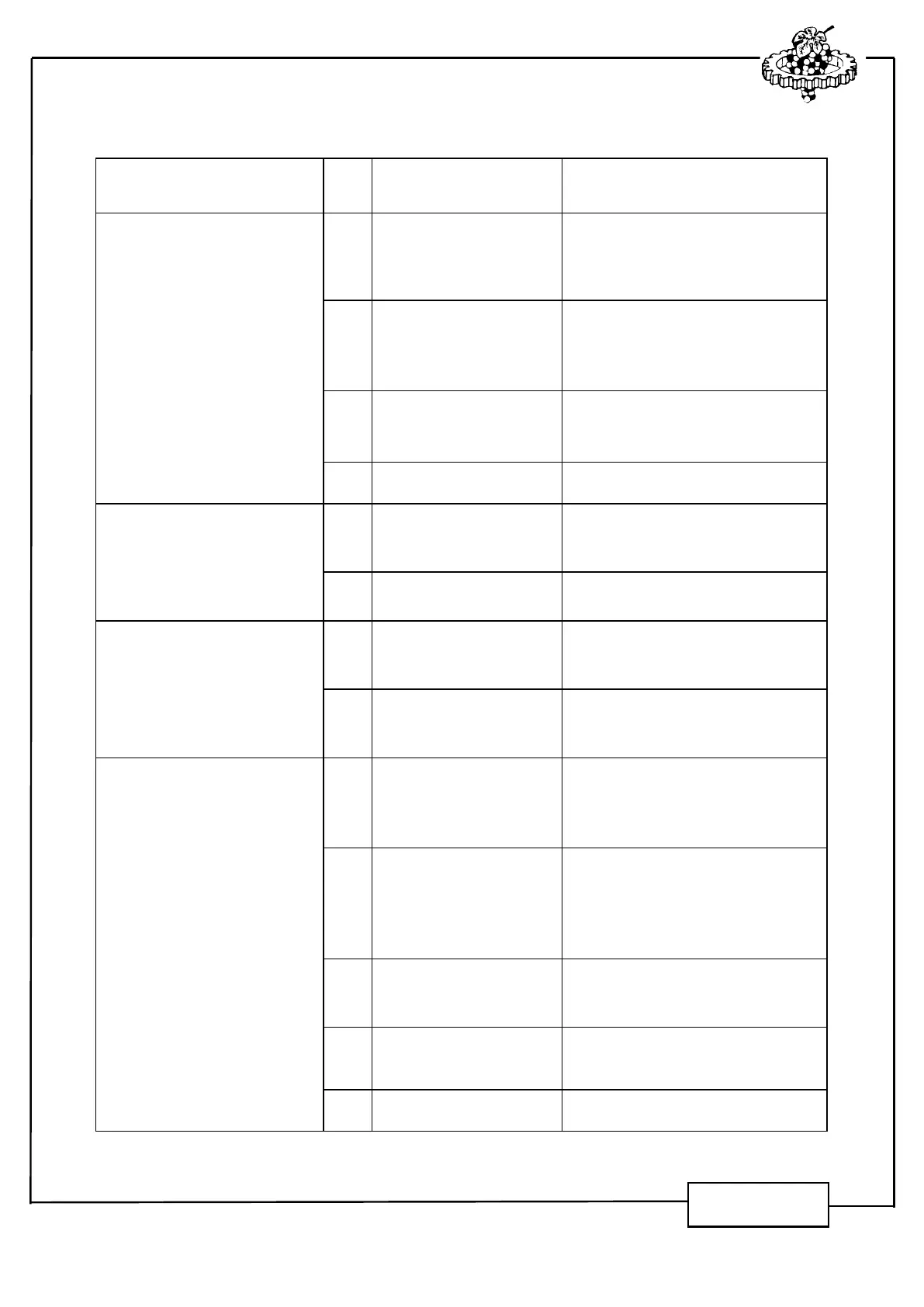

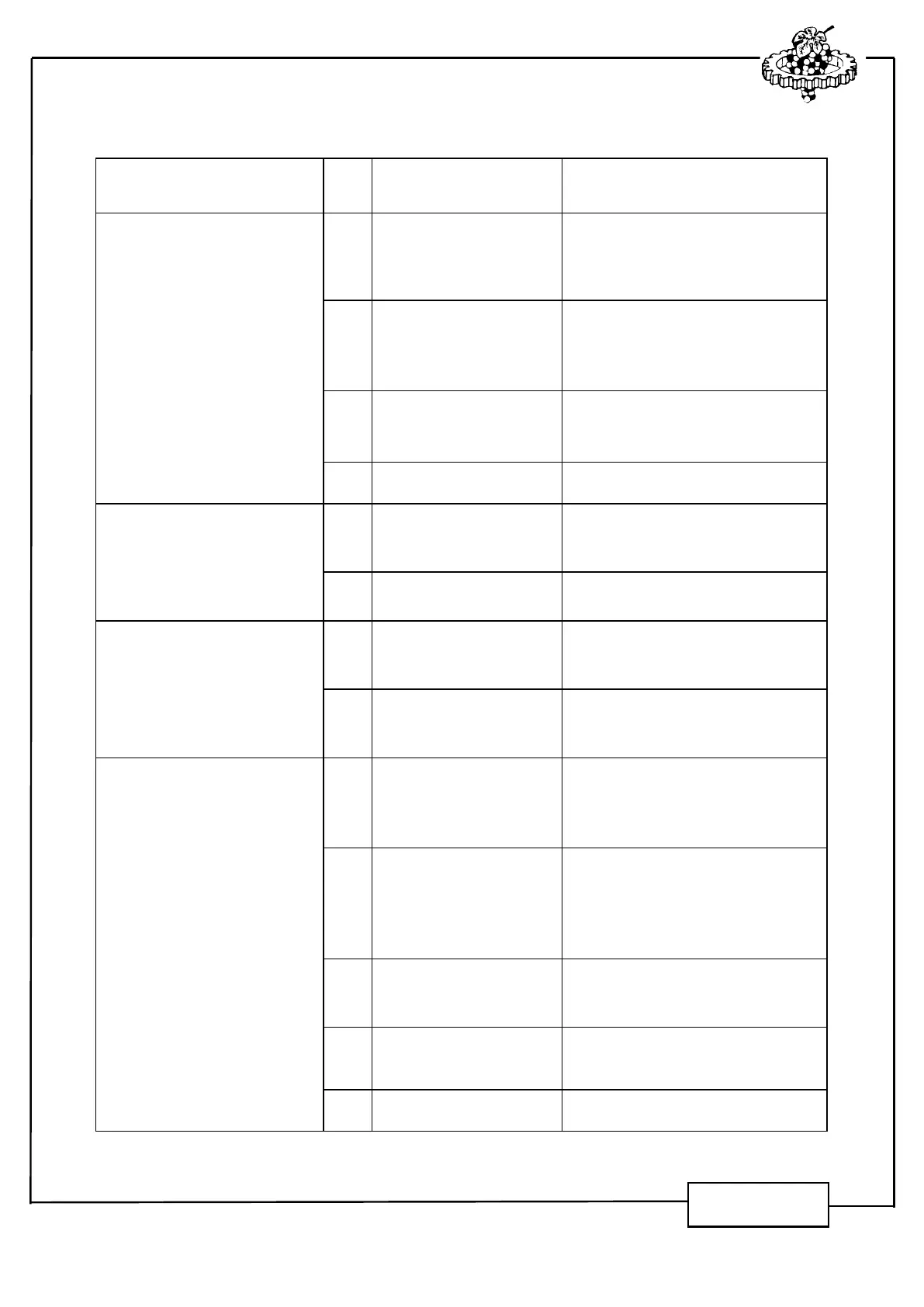

CAS PROBABLE CAUSE CHECKS - REMEDIES

Calibration of pressure

relief valves too low (or

impurity on the valve

seat)

Increase pressure to the

recommended value or clean unit

Motor is worn out or

deteriorated, too much

internal play

Check the oil flow on the drainage. If

the flow is too high, change the

motor, clean the hydraulic circuit,

change the filters

Check the increase in pressure on

the pump or change the pump if

necessary

4 Filter clogged Check the filter, change if necessary

Type of oil is not suitable

for the trimmer (too liquid

at hig temperature)

Check the oil and change if

necessary for a suitable type

6 Motor or pump worn out See cases 2 or 3

Calibration of pressure

relief valves too low

Increase pressure to the

recommended value or clean

Oil not suitable (viscosity

too high at low

temperature)

Check the oil and change if

necessary for a suitable type

Change to a higher capacity relative

to the flow of the pump

Compare the maximum oil flow of

the pump of the tractor with the

maximum oil flow acceptable by the

machine. Contact your dealer for

more informations.

Type of oil is not suitable

(viscosity too high)

The oil is being reduced

inside pressure relief

valve

Regulate pressure in the pressure

relief valve to the recommended

level

Clogging of the filter

element

Note : The interventions on the hydraulic system must be done by approved techniciens,

except for the change of the cartridge filter.

PROBLEMS WHICH MAY OCCUR AFTER SWITCHING ON THE UNIT

The blades rotate too

slowly, in spite of a good

output control but speed

increases proportionally

at the temperature

The blades rotate normally

at cold temperature, but

slow down when the

temperature is stabilized

The blades rotate too

slowly, even though the

oil flow corresponds to

recommendations and

even after several

minutes of operation

The temperature

of the circuit is

too high ( > 70°C )

Loading...

Loading...