76

5

6

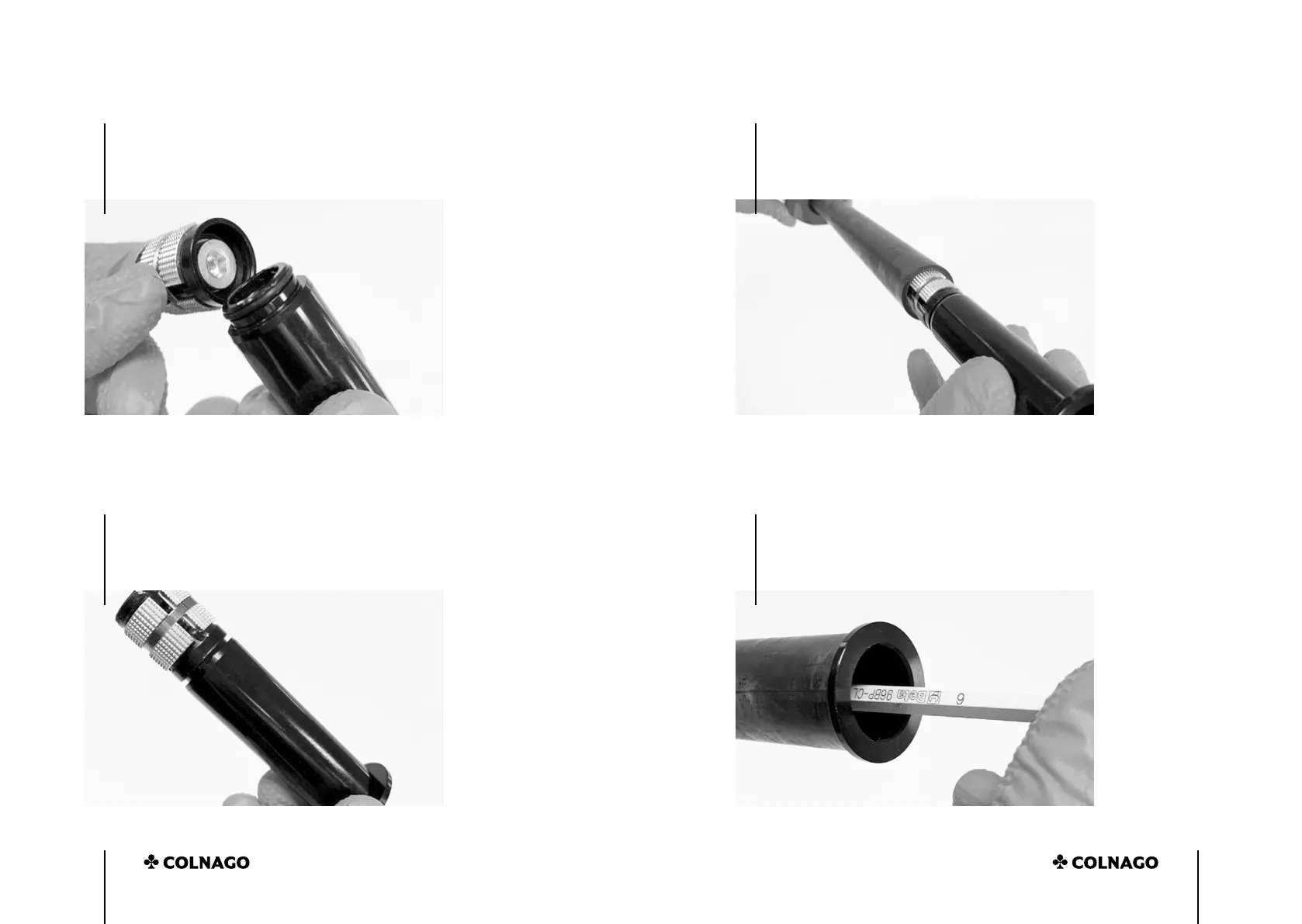

Take the fork expander and make it loose with a 6 millimiter Allen

key, just enough to get it through the fork tube . Get it stuck together

with the black metallic sleeve with the help of the o-ring.

This is the fork expander assembly. The two pieces are kept

togheter with the friction generated by the o-ring, but can be easily

disassembled.

7

8

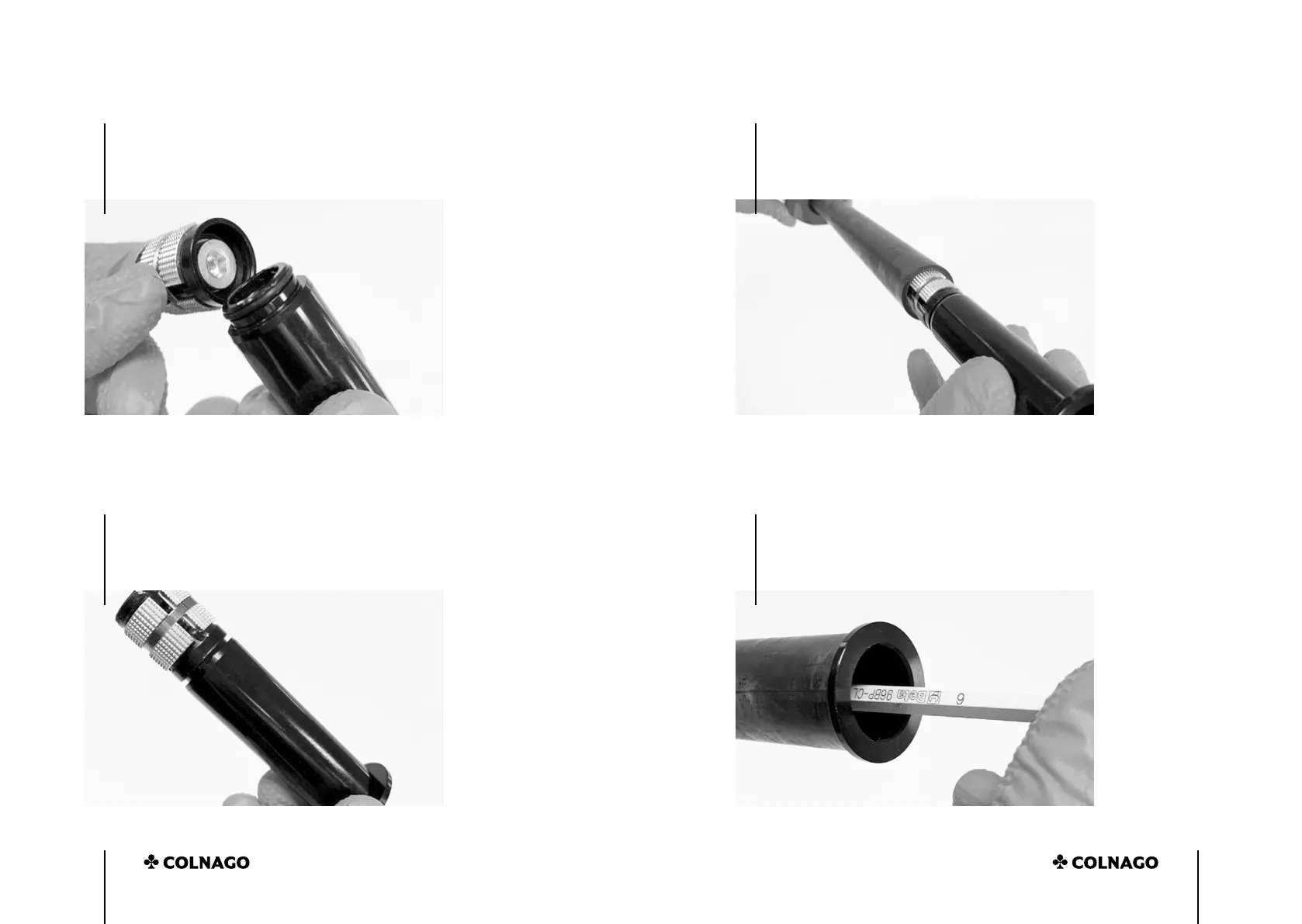

After the fork has been cut to the desired height, insert the assembly

into the fork tube, until the metallic sleeve’s upper edge bottoms out

with the fork.

Use the 6 millimeter Allen key to tight the expander in position.

Tightening torque: 4 Newton Meters. Make sure no grease or

contaminants are present on the inner surface of the fork tube.

Loading...

Loading...