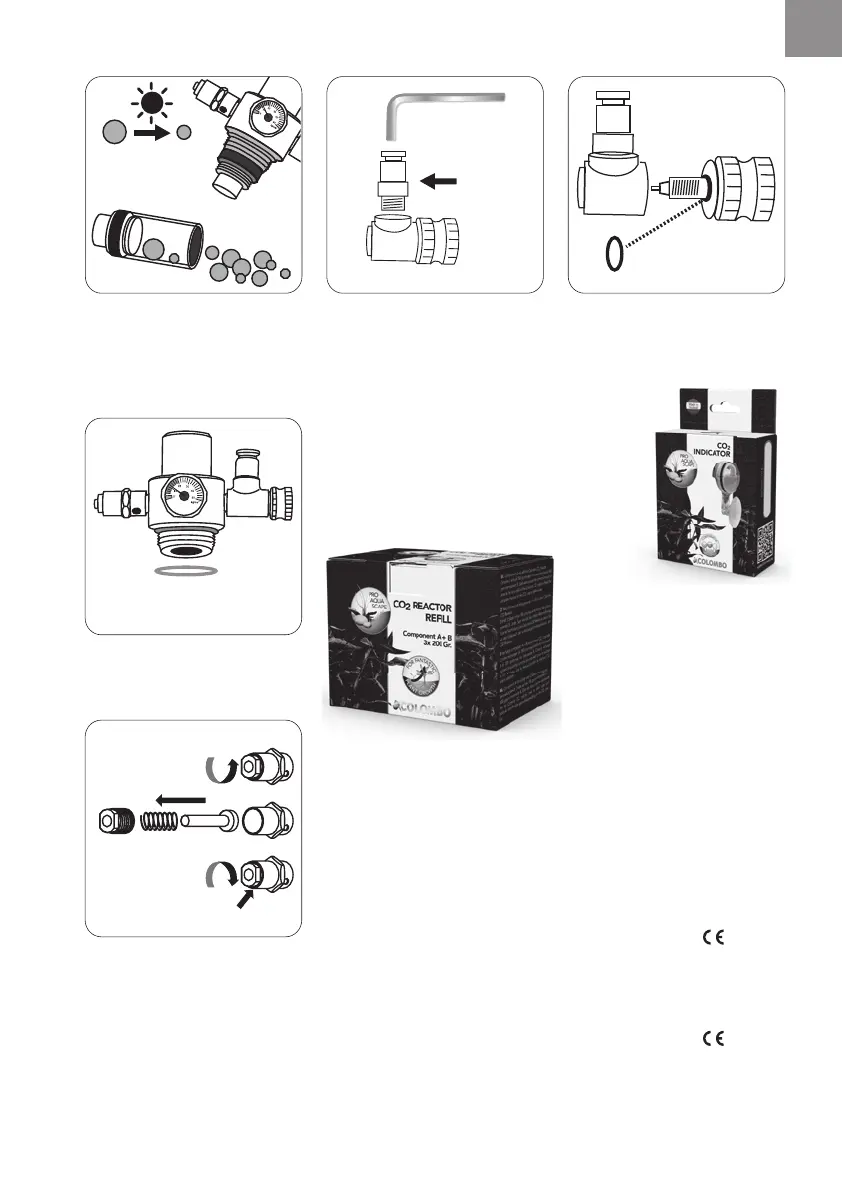

The lter media in the moisture lter can be

dried. An additional lter is included in the

set, you can use this while the other lter is

drying.

A spare fast-t connector for the bubble

counter is included. When required the fast-

t connector can be replaced, screw it on or

o with the Allen wrench included in the set.

Use the optional Colombo CO

2

indicator to continuously monitor

the CO

2

concentration of the aquarium water. The supply of CO

2

must be disconnected at night because plants do not absorb CO

2

when it is dark. The supply of CO

2

can be stopped automatically by

connecting the solenoid to a domestic timer.

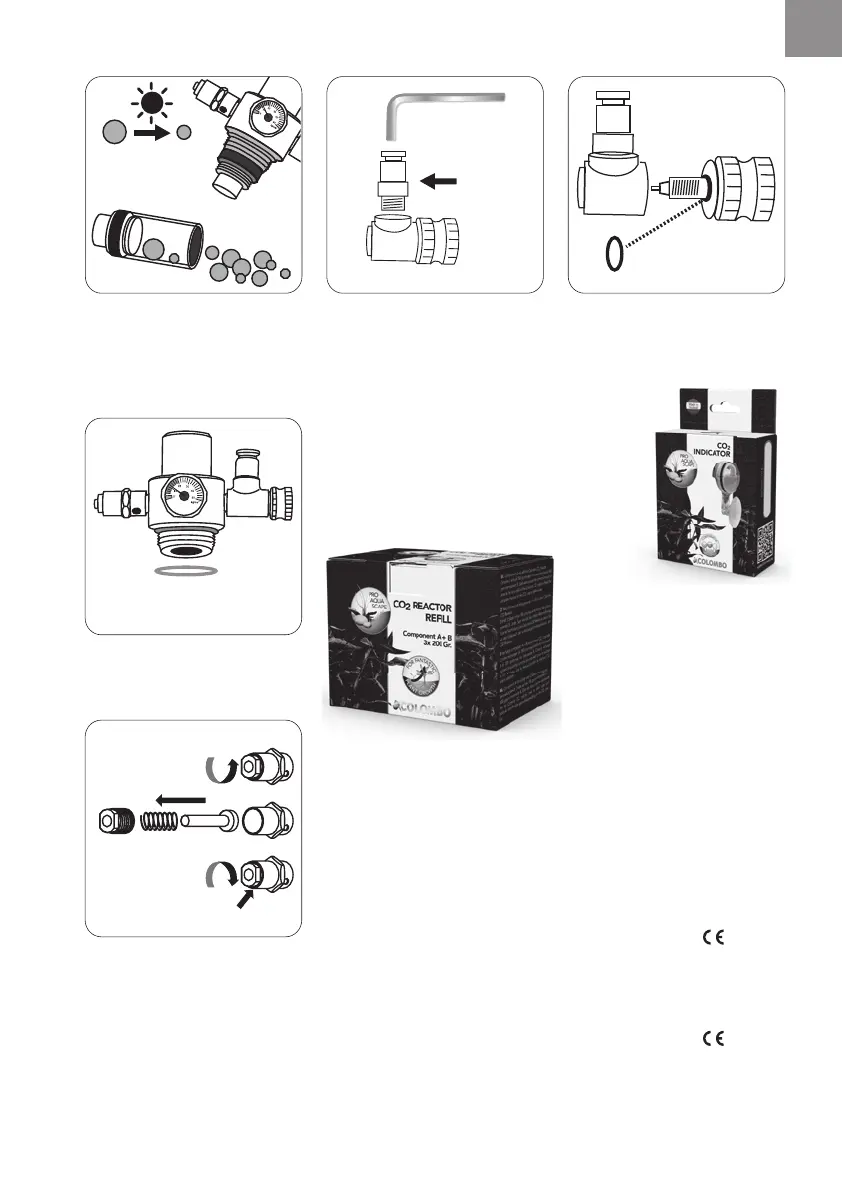

Only use the Colombo CO

2

reactor rell for

your CO

2

reactor. The Colombo CO

2

reactor

rell contains the correct raw materials of

premium quality, ensuring the correct

results in a safe way.

Frequently asked questions:

Why is the pressure lower than 22 bar after the chemical reaction has taken place?

Maximum pressure is achieved 24 hours after the chemical reaction has taken place.

The pressure regulator is not fitted quickly enough after the water has been added.

The pressure is normal, why I don’t see bubbles in the bubble counter?

Check if the red lamp burns on the solenoid, when the lamp is on the solenoid is open.

Check if the bubble counter is filled with water

The gas is still owing after the solenoid is closed.

CO

2

gas will still be released from the diffusor, this will stop after some time.

Technical data

Cilinder

• Year of manufacture: see on bottle

• Max. pressure = 40 bar

• Burst pressure > 100 bar

• Volume(n) = 2.4 ltr

• Max.lling mass = 400 gr

component A+B

• Tarre mass = 1.1 kg

• CE-marking

Safety Valve

• Year of manufacture: see safety

valve label

• Max. relief pressure = 40 bar

• CE- marking

Distributed by: Colombo B.V., Franse Akker 7

4824 AL, Breda, The Netherlands

Tel: +31-(0)76-3038727,

Email: info@colombo.nl, www.colombo.nl

The O-ring in the adjustment knob can be

replaced. Turn the adjustment knob

anticlockwise until it releases from the

housing to access the O-ring.

The green O-ring on the pressure regulator is

included as a spare part, when required it

can be replaced.

When the safety valve has become active or

when it is dirty, disassemble the valve and

clean it properly. Assemble the valve and see

to it that the plain of the nut and the valve

body are levelled as indicated in the

drawing.

Maintenance and spare parts:

Line up with edge

UK

O-ring

Pressure regulator

O-ring

adjustment knob

Replace to dry Fast-t connector

Loading...

Loading...