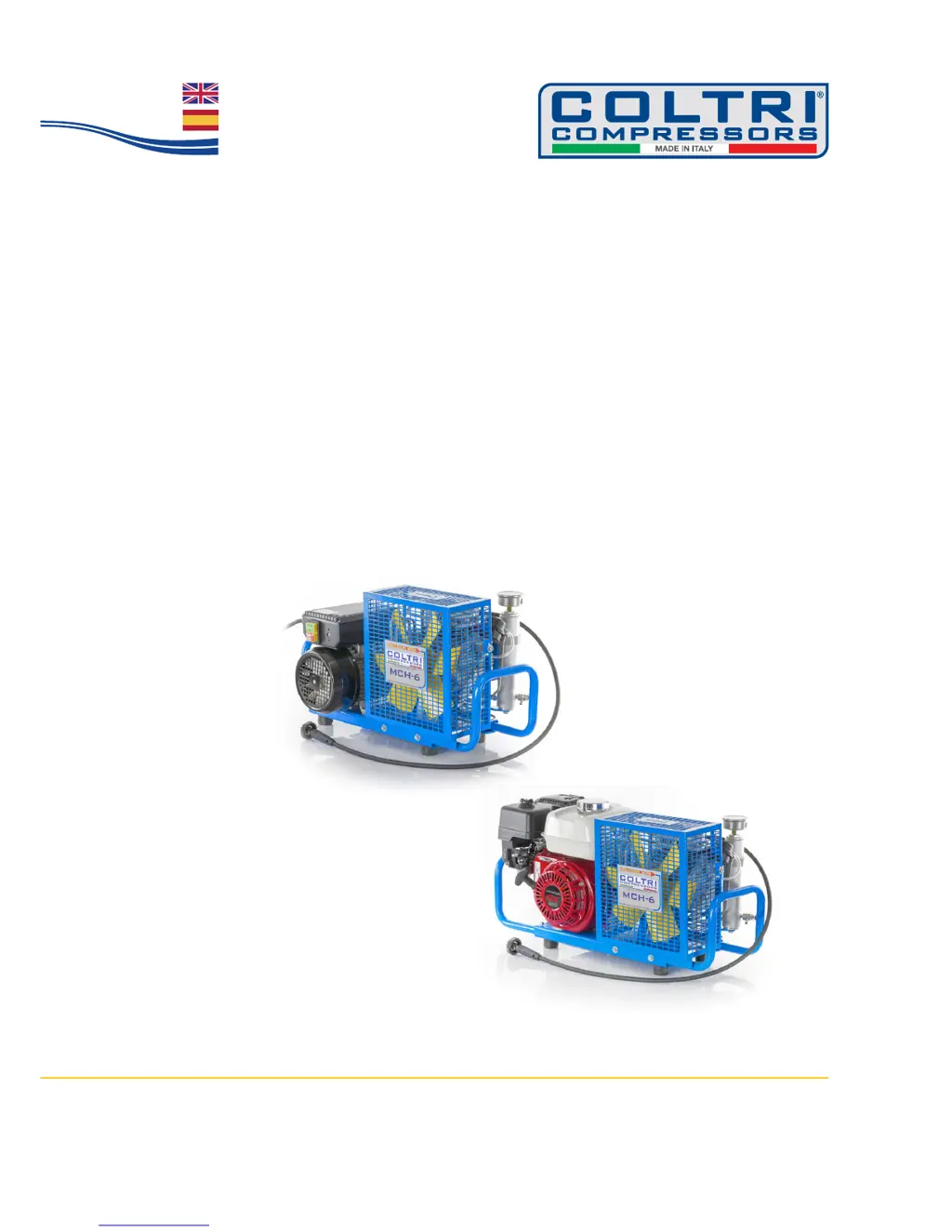

Why is my Coltri Compressors MCH-6/SH overheating?

- JJamie HamiltonAug 3, 2025

Your Coltri Compressors Air Compressor may be overheating due to several reasons. It could be that the direction of rotation is wrong, so you should correct the rotation. Other potential causes, such as dirty cooling tubes or incomplete valve closure, require contacting technical assistance.