First issue 10/14 Release A10/14

PGRF 3/9

GENERAL INFORMATION

All the data which characterize the gear unit are reported on the name plate attacched on

the unit.

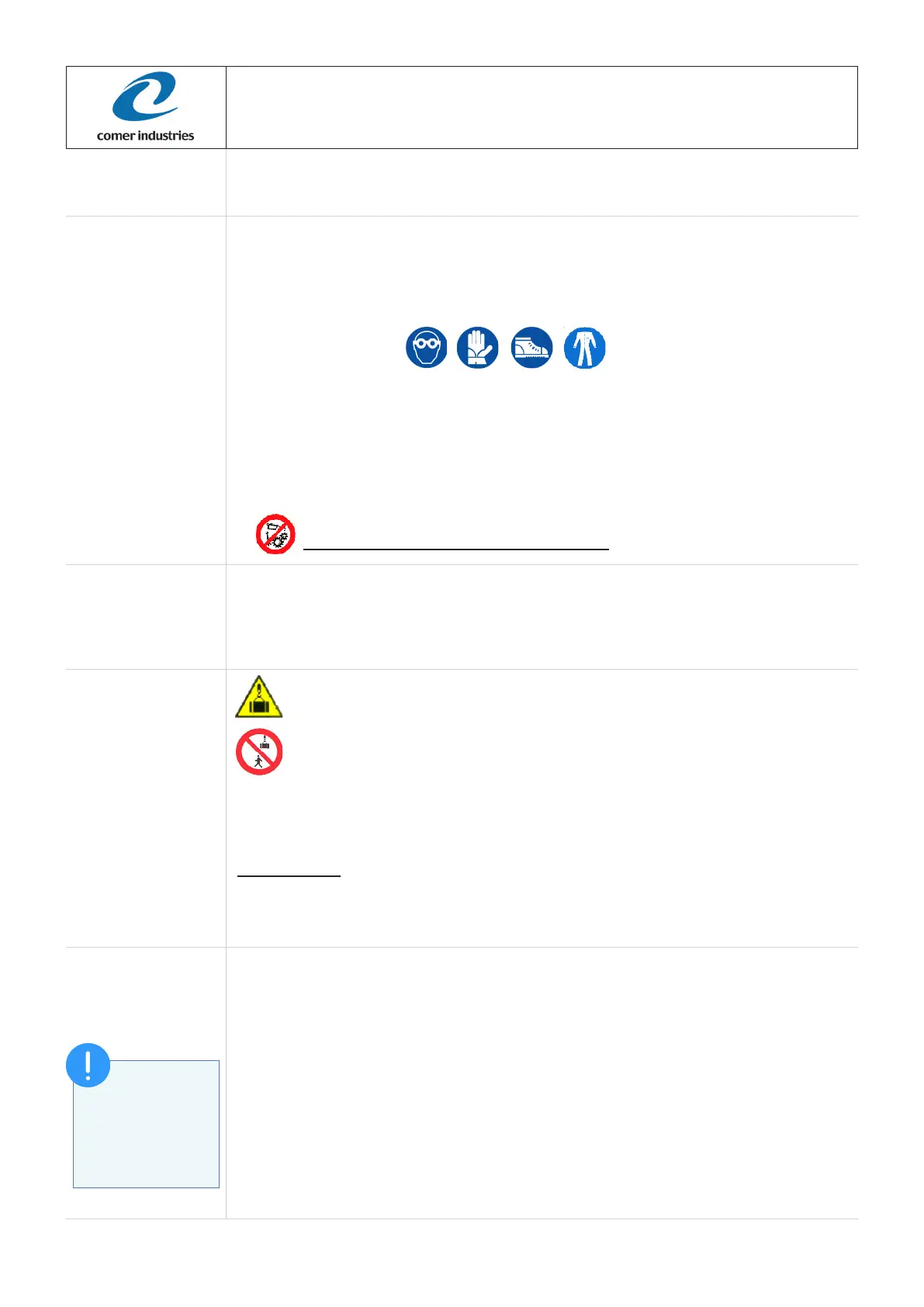

GEARBOX UNIT

IDENTIFICATION

HANDLING

Handling,liftingandtransportationmustbecarriedoutbyqualied,

authorized and appropriately trained personnel.

Before and during unit handling:

• check the stability of the unit;

• verify that the lifting means and its accessories (ropes, hooks, etc.) are

suitable to lift and handle the unit;

• follow strictly the regulations in force for security and prevention of

industrial injuries.

Manual loads:

If the unit or its parts must be handled manually, limit the load to 10Kg.

We recommend lifting the load by keeping it as close as possible to the body and bending

the knees and not the back.

TRANSFER AND

STORAGE

The unit is best stored in closed and covered environments.

Do not store the unit ouside or directly onto the ground.

If the unit is stored for long periods (over 3 month), these must be externally protected with

anti-oxidizingproductsandlledwithoiltoprotecttheinternalcomponents.

Care should also be used to avoid violent impact.

Safety of authorized workers must be guarantee.

Provide allauthorizedworkerwithallnecessaryandspecicIPG.

Example: Slip-proof shoes should be worn, because there is oil in the reduction gear and

during maintenance some of it may leak in the working area.

Always handle the units with adequate lifting means.

RISKS AND

PRECAUTIONS

ADDITIONAL PRECAUTIONS

• Guarantee an effective prevention system by constantly monitoring cleaning and

integrity of the structures.

• Actuateaspecicperiodical cleaning and maintenance plan of the unit.

• In case of accidental overloads or damage to the unit, stop functioning unit and carry

out a repairing procedure.

Do not work with machines in movement.

PRODUCT

DISPOSAL

The disposal of waste material deriving from machine/components demolition must be

done with respect for the environment, without polluting land, air or water.

Dismantling: parts and components must be disassembled and separated in according to

the materials they are made of: iron, aluminium, copper, plastic, rubber, etc.

Components and parts must be disposed of by the relative centres in full compliance with

the laws in force on the matter of dismantling and demolishing industrial waste.

Packages (pallets, carton boxes, paper, plastic, etc.) to lead into regeneration/recycling

circuits as far as possible, by delivering separate waste classes to authorized compaines.

Waste oil/grease: to dispose of waste oil abide by the laws for protecting the environment

and the laws in force in the Country where the machine is used.

Environmental

protection:

Local rules must be

complied with in regard

to the laws existing in

the country where the

machine is used

Loading...

Loading...