84

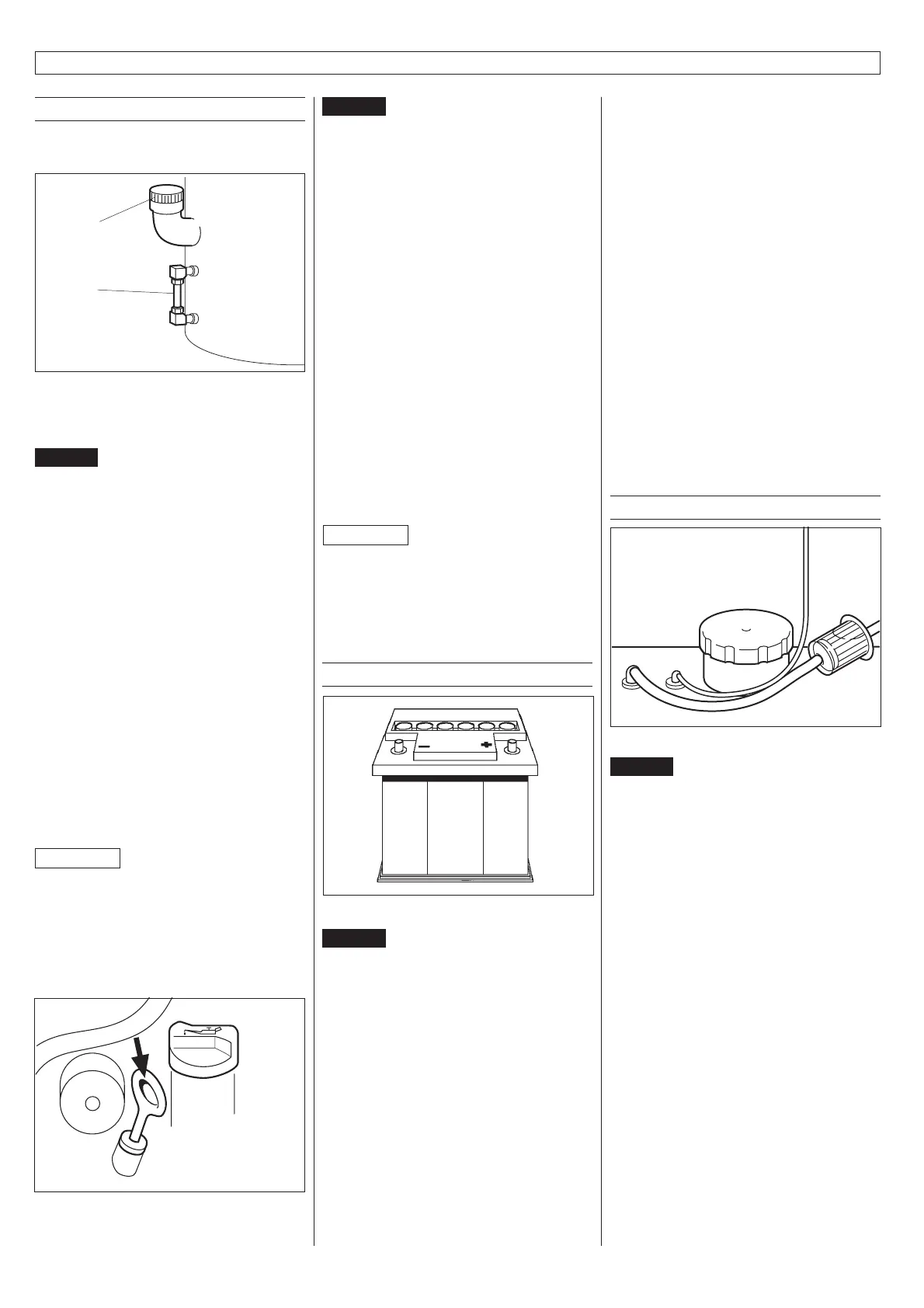

6.1 Checking oil levels

6.1.1 Checking the oil level in the

pressure tank

Fig. 12

1 Inspection glass

2 Oil filler plug

Danger

Only check the oil level when the engine

is at a standstill and the compressor is

not under pressure.

The pressure tank may be under

pressure and the oil may be hot.

Risk of scalding! Spill no oil!

Check for leaks.

Proceed as follows:

* Before checking the oil level in the

engine and in the compressor ensure

that the vehicle is standing horizontally.

* Ensure that the screw compressor has

been out of operation for some time.

* Check oil level in the inspection glass

* The oil level must be in the middle of the

visible range.

* Correct as required.

Attention

After a short test run, the oil level

must be in the middle of the visible

range. For oil specifications, see

recommended lubricants, Chapter 8.1.

6.1.2 Checking the oil level in the engine

Fig. 13

Danger

Only check the oil level when the

compressor engine is at a standstill.

Spill no oil! The oil may be hot. Risk

of scalding!

Check for leaks.

Proceed as follows:

* Ensure that the screw compressor is

standing horizontally.

* Ensure that the screw compressor has

been out of operation for some time.

* Unscrew dipstick.

* The oil level should be as near as

possible to the upper dipstick mark.

* Correct as required.

* Screw in dipstick.

* Close oil filler.

* For oil specifications, see “Engine

Operating Manual”.

Attention

After a short test run, the oil level must

not be above or below the upper or

lower dipstick marks. For oil specifi-

cations, see engine instruction manual.

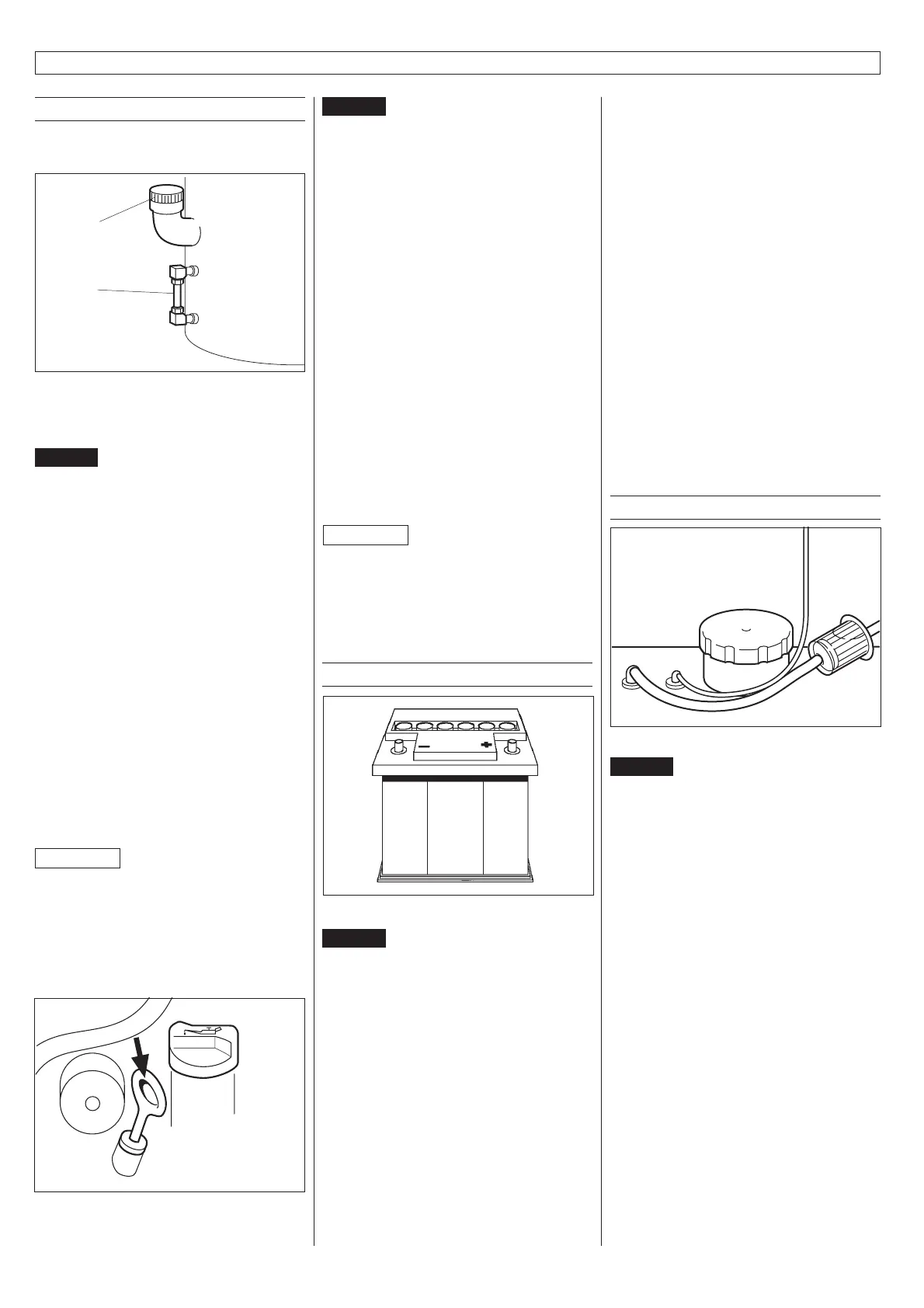

6.2 Battery

Fig. 14

Danger

When working with battery acid (electro-

lyte), wear acid-resistant goggles,

gloves and apron.

The gases released by the battery are

explosive. Avoid sparks and open fires

in the vicinity of the battery.

Do not allow acids to come into contact

with skin or clothing. Wear safety

goggles.

Place no tools on the battery.

The battery is filled and charged in

accordance with DIN 43539. The battery is

fastened with clamping strips.

The batteries used are ready to be

installed and ready for service.

Replacement batteries should be of the

same type as the batteries installed

(low gassing). The replacement battery

should be unfilled and only be preloaded

so that it has to be filled with battery

acid. The battery and the acid should

have a temperature of at least +10 °C.

Proceed as follows:

* Fill up with battery acid as far as the

base of the control insert

* Leave the battery to stand for some time

* Then shake it gently

* If required, top up with acid

* Tighten sealing caps

* The battery is ready for use

* Leave for 1 hour

6.3 Filling up the fuel tank

Fig. 15

Danger

Only fill up with fuel when the screw

compressor is at a standstill.

Cleanliness is essential! Spill no fuel!

Filling up at a pump can cause static

electricity and possibly sparks.

Proceed as follows:

* Open tank lid

* Fill up tank with commercially available

branded diesel fuel, using a sieve (use

summer or winter diesel fuel depending

on outside temperatures)

* Close tank tight with tank lid

* With the Deutz engines FM1011, the

injection pump is self-ventilating. When

the tank is empty, immediately fill in fuel

to ensure that the fuel pump is always

filled with fuel. This condition may result

in starting problems.

* Close hood.

6. Preparing the compressor for operation

2

1

Loading...

Loading...