76

4. Construction and functional description

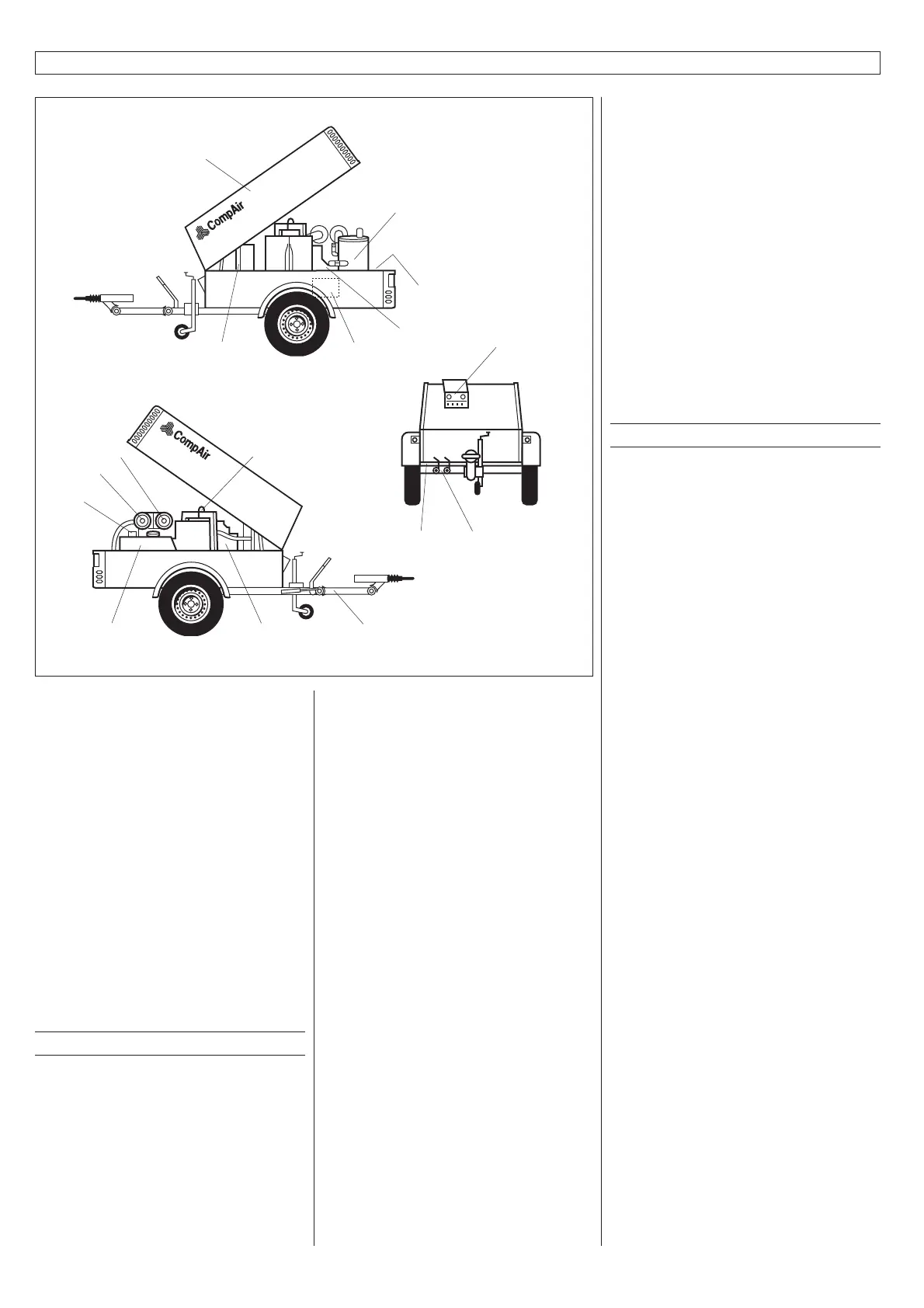

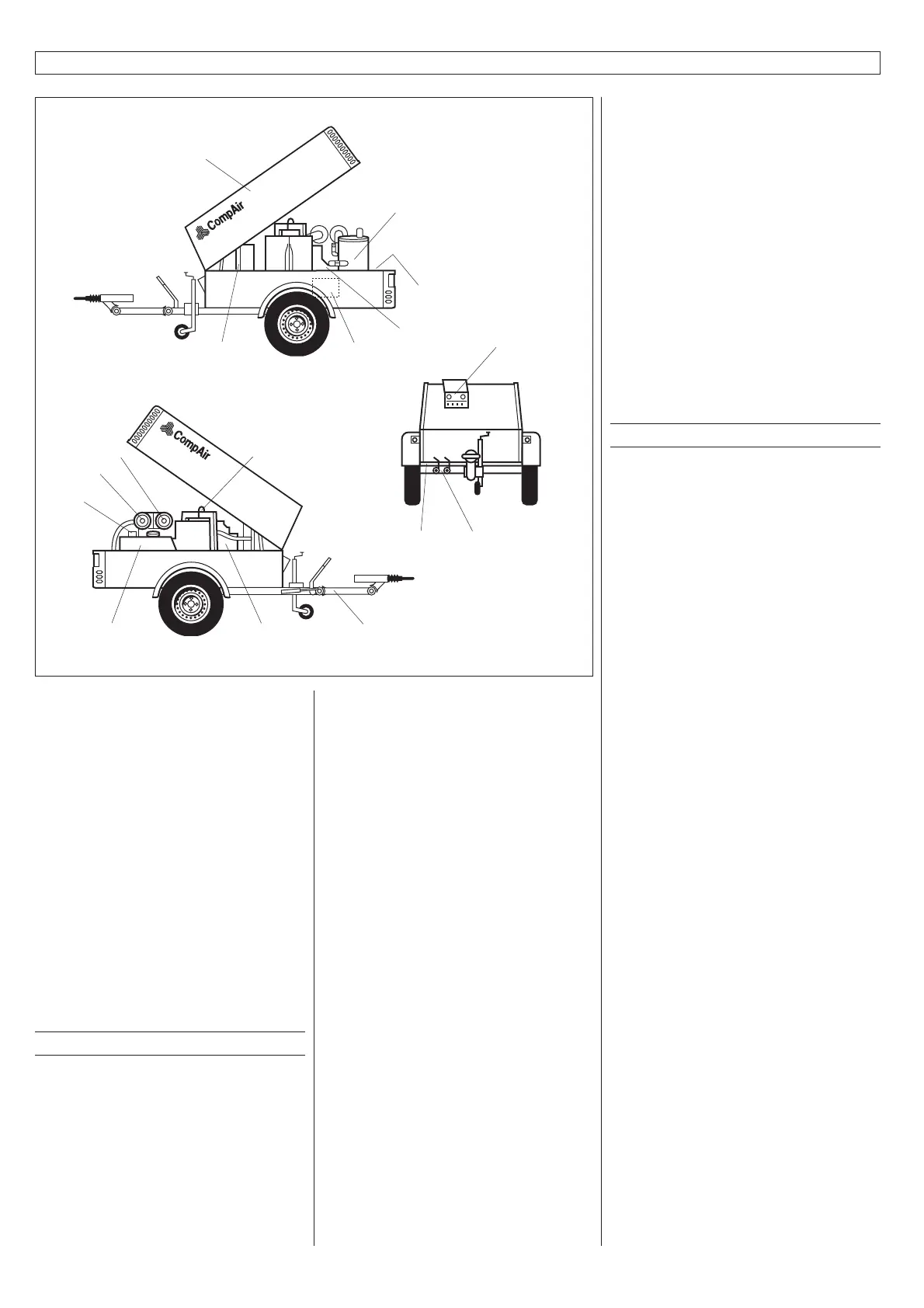

Fig. 3

1. Screw compressor

2. Instrument panel

3. Pressure tank

4. Oil cooler

5. Oil filter (compressor)

6. Air filter (compressor)

7. Air filter (engine)

8. Taps

9. Hood

10. Fuel tank

11. Battery

12. Diesel engine

13. Chassis

14. Tool oiler

15. Crane ring

16. Vehicle and chassis type identification

number

4.1 Construction

Compressor and engine

The DLT 0404 series is a sound proofed

mobile compressor system. The core is a

single-stage, oil-flooded screw compressor.

The CompAir screw profile represents the

state-of-the-art. The air is delivered

pulsation-free.

Frame and chassis

The complete compressor unit is

mounted on an easy-to-transport single-

axle chassis. The chassis is equipped

with automatic overrun brakes and

parking brakes, as well as a jockey wheel

adjustable in height.

Airflow

Fresh air is sucked in through the

admission opening at the back of the

compressor. The air intake volume is

air for the engine and for the compressor

too, as well as cooling air for the engine

and for the oil cooler of the compressor.

4.2 Functional description (see fig.4)

Oil circuit

The oil required for sealing and cooling

the rotors as well as for lubricating the

roller bearings is injected into the

compressor (23) from the pressure tank

(13), which is under system pressure. The

difference in pressure between the

pressure tank and the oil injection position

is approx. 1 bar. The oil hereby passes the

oil cooler (20) and the oil filter (19). The

intake control valve (2) is fitted with a non-

return function, so that when the system is

switched off, flooding of the air filter (1) is

prevented.

Air circuit

The intake air flows through the air filter

(1) and the suction control valve (2) into the

compressor (23). During compression, oil is

injected in order to lubricate, cool and seal

the screw rotors. The compressed air-oil

mixture flows into the pressure tank (13).

Centrifugal preseparation of the oil is

ensured through tangential entry into the

tank.

Any remaining oil is separated from the

air in the fine separator.

The compressed air is fed via the Venturi

nozzle (11) / the pressure retention valve

(option) to the compressed air discharge.

The venturi nozzle (11) effectively prevents

the system pressure from falling below the

minimum operating pressure required for

the system to work properly. A temperature

monitoring device (22, 6) as well as an

operational pressure manometer are

integral parts of the air circuit.

The drive assembly is a medium-cooled

diesel engine, which drives the screw

rotors of the compressor by a flexible

coupling.

Shielding (Body)

The shielding consists of a low box

mounted on a base-frame. A cover, which

can be opened wide for servicing is fixed to

the base-frame. The opening of the cover

is effectively supported by pneumatic

springs. The hook inside is for hanging up

a load suspension device. The machine

rests on rubber elements to prevent

vibrations and noise.

For convenient assembly, all individual

parts of the cover are screwed together

with machine screws. For the prevention of

corrosion, the compressor body is fully

galvanised, electrostatically powder coated

and burnt at °C 220. The sound absorbing

mats are inserted and easy to be cleaned.

13

9

15

4

12

10

6

3

7

11

16

1

5

8

2

14

Loading...

Loading...