UNPACKING

Thisproducthasbeenshippedcompletelyassembled.

[] Carefullyliftthesawfromthecartonandplaceitona

levelworksurface.

[] hspectthetoolcarefullytomakesurenobreakageor

damageoccurredduringshipping.

[] Donotdiscardthepackingmatedaluntilyouhave

carefullyinspectedandsatisfactorilyoperatedthetool.

[] Thesawisfactorysetforaccuratecutting.After

assemblingit,checkforaccuracy.Hfshippinghas

influencedthesettings,refertospecificprocedures

explainedinthismanual.

[] Hfanypartsaredamagedormissing,pleasecall

1-800-932-3188forassistance.

A

WARNING: Hfany parts are missing, do not operate

this tool until the missing parts are replaced. Failure

to do so could result in possible serious personal

injury.

WARNING: Do not attempt to modify this tool

or create accessories not recommended for use

with this toot. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING: Do not connect to a power supply unti!

assembly is complete. Failure to comply could result

in accidental starting and possible serious personal

injury.

MOUNTING SCROLL SAW TO WORKBENCH

WARNING: To avoid serious personal injury from

unexpected tool movement, always securely mount

scroll saw to a workbench.

If the scroll saw is to be used in a permanent application,

we recommend that you secure it in a permanent loca-

tion such as a workbench. When mounting the saw to a

workbench, holes should be drilled through the supporting

surface of the workbench.

[] Each hole in the base of the saw should be bolted

securely using machine bolts, washers, and nuts (not

included). Bolts should be of sufficient length to ac=

commodate the saw base, washers, nuts, and the

thickness of the workbench.

[] Place scroll saw on workbench. Using the saw base as

a pattern, locate and mark the holes where the scroll

saw is to be mounted.

[] Dril! three holes through the workbench.

[] Place scroll saw on workbench aligning holes in the

saw base with the holes ddIled in the workbench.

[] Insert al! three bolts (not included) and tighten securely

with washers and nuts (not included).

NOTE: Al! bolts should be inserted from the top. Install

the washers and nuts from the underside of the bench.

The supporting surface where the scrol! saw is mounted

should be examined carefully after mounting to insure

that no movement during use can result. If any tipping or

walking is noted, secure workbench or supporting surface

before beginning cutting operations.

To Reduce Noise and Vibration:

You may wish to place a foam pad or piece of carpet

between the saw base and the workbench to help reduce

noise and vibration.

If a foam pad or piece of carpet is used, do not overtight=

en the mounting bolts. Leave some cushion between the

padding and the saw base to help absorb the noise and

vibration.

The size of the padding material should be approximately

24 in. x 12 in. x 1,/2 in.

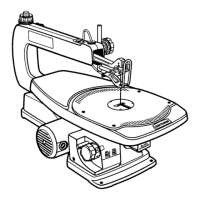

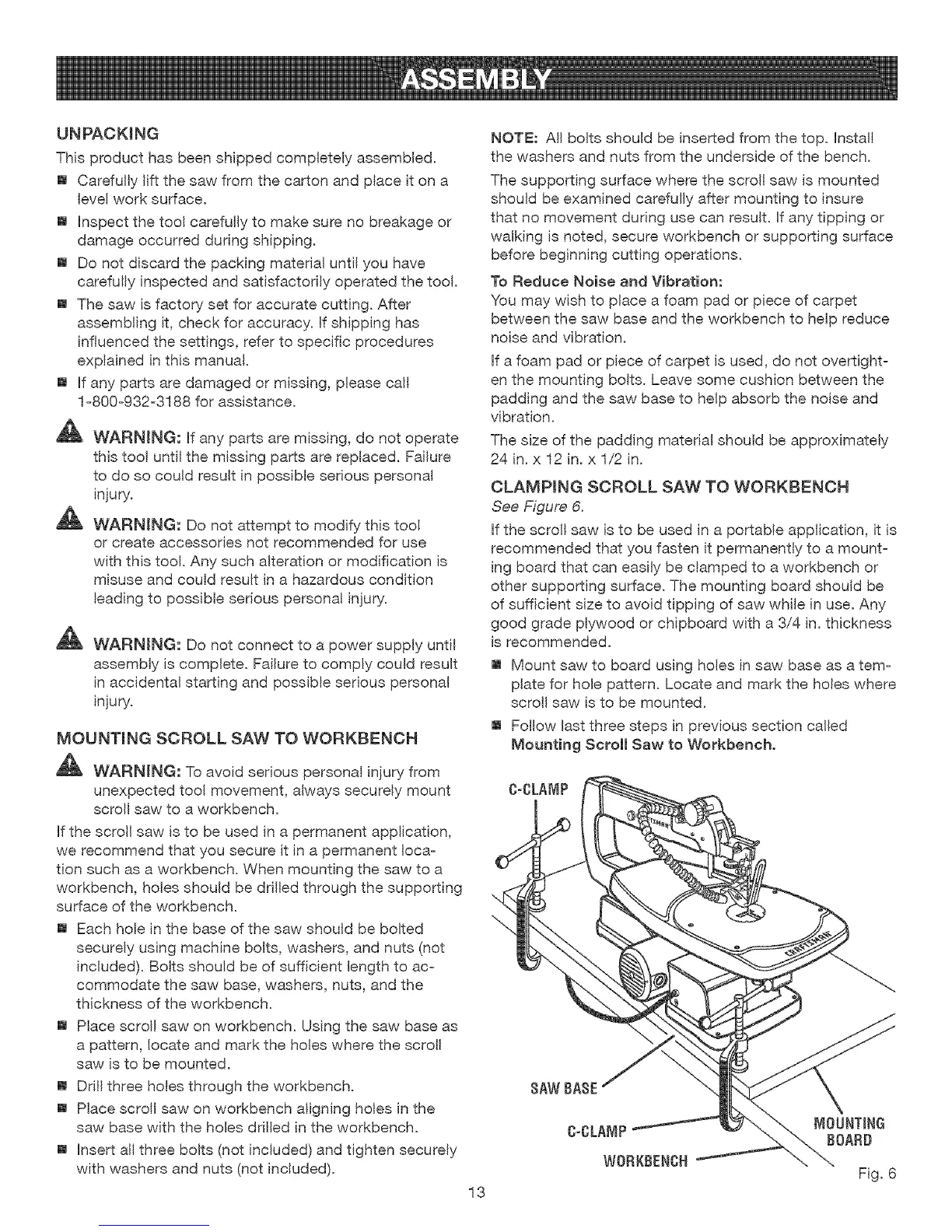

CLAMPING SCROLL SAW TO WORKBENCH

See Figure 6.

If the scroll saw is to be used in a portable application, it is

recommended that you fasten it permanently to a mount-

ing board that can easily be clamped to a workbench or

other supporting surface. The mounting board should be

of sufficient size to avoid tipping of saw while in use. Any

good grade plywood or chipboard with a 3/4 in. thickness

is recommended.

[] Mount saw to board using holes in saw base as a tern=

plate for hole pattern. Locate and mark the holes where

scrol! saw is to be mounted.

[] Fol!ow last three steps in previous section called

Mounting Scroll Saw to Workbench.

\

13

8AWBABE

C-CLAMP MOUNTING

BOARD

WORKBENCH

Fig. 6

Loading...

Loading...