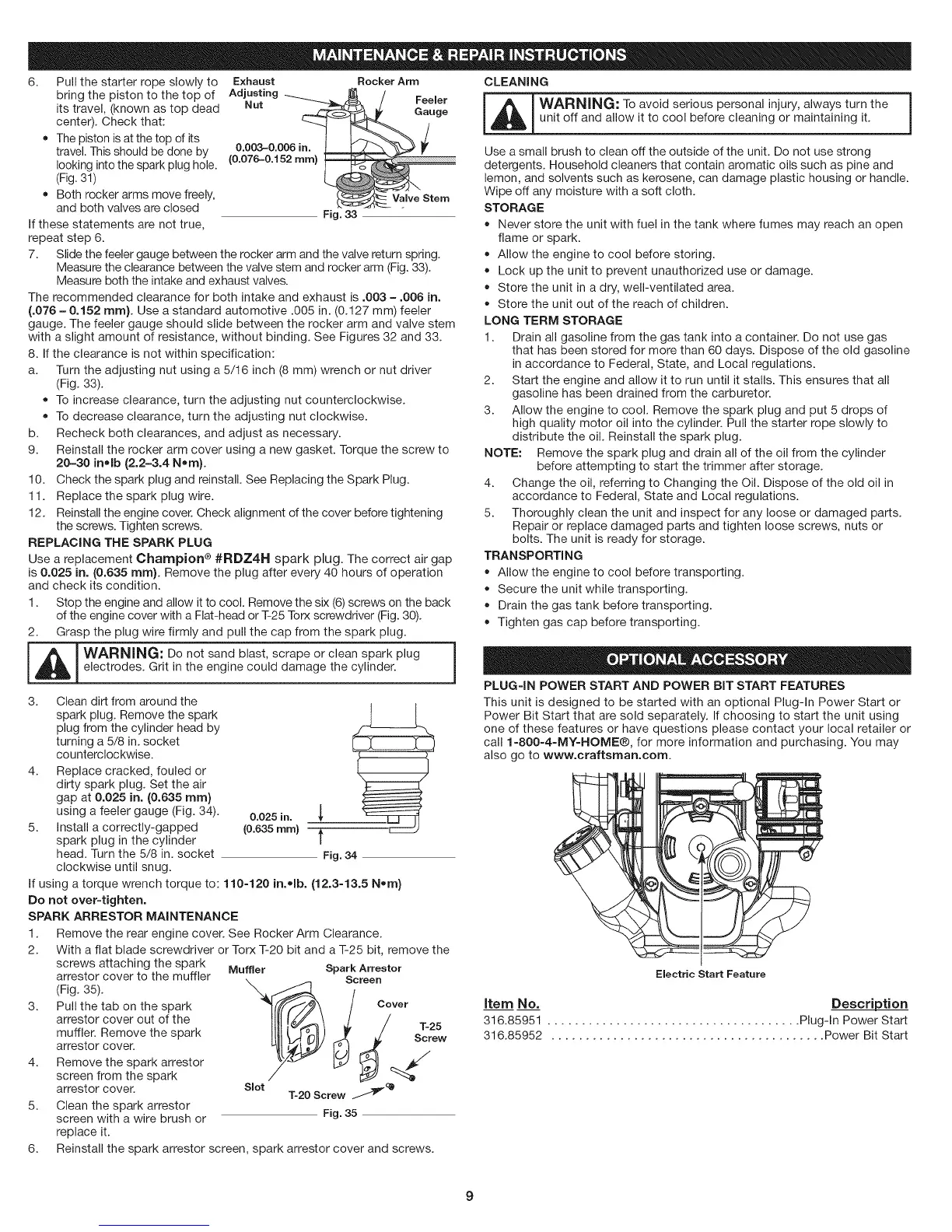

6. Pull the starter rope slowly to Exhaust Rocker Arm

bring the piston to the top of Adjusting _tt /

Nut "--"_-_ / Feeler

its travel, (known as top dead _ _, Gauge

center). Check that:

t

• The piston is at the top of its ,/

travel. This should be done by 0.003-0.005 in. _ "_._

p,

looking into the spark plug hole. (0.076-0.152 ram)

(Fig.31)

• Both rocker arms move freely,

and both valves are closed _Valve Stem

Fig. 33

If these statements are not true,

repeat step 6.

7. Slide the feeler gauge between the rocker arm and the valve return spring.

Measure the clearance between the valve stem and rocker arm (Fig. 33).

Measure both the intake and exhaust valves.

The recommended clearance for both intake and exhaust is .003 - .006 in.

(.076 - 0.152 rnrn). Use a standard automotive .005 in. (0.127 mm) feeler

gauge. The feeler gauge should slide between the rocker arm and valve stem

with a slight amount of resistance, without binding. See Figures 32 and 33.

8. If the clearance is not within specification:

a. Turn the adjusting nut using a 5/16 inch (8 mm) wrench or nut driver

(Fig. 33).

• To increase clearance, turn the adjusting nut counterclockwise.

• To decrease clearance, turn the adjusting nut clockwise.

b. Recheck both clearances, and adjust as necessary.

9. Reinstall the rocker arm cover using a new gasket. Torque the screw to

20=30 in,lb (2.2-3.4 N,rn).

10. Check the spark plug and reinstall. See Replacing the Spark Plug.

11. Replace the spark plug wire.

12. Reinstall the engine cover. Check alignment of the cover before tightening

the screws. Tighten screws.

REPLACING THE SPARK PLUG

Use a replacement Champion ® #RDZ4H spark plug. The correct air gap

is 0.025 in. (0.635 rnrn). Remove the plug after every 40 hours of operation

and check its condition.

1. Stop the engine and allow it to cool. Remove the six (6) screws on the back

of the engine cover with a Flat-head or T-25 Torx screwdriver (Fig. 30).

2. Grasp the plug wire firmly and pull the cap from the spark plug.

-- ]

I ,_ I WARNING: Do not sand blast, scrape or clean spark plug

the

engine could damage the cylinder.

_ electrodes. Grit in

3. Clean dirt from around the

spark plug. Remove the spark

plug from the cylinder head by

turning a 5/8 in. socket

counterclockwise.

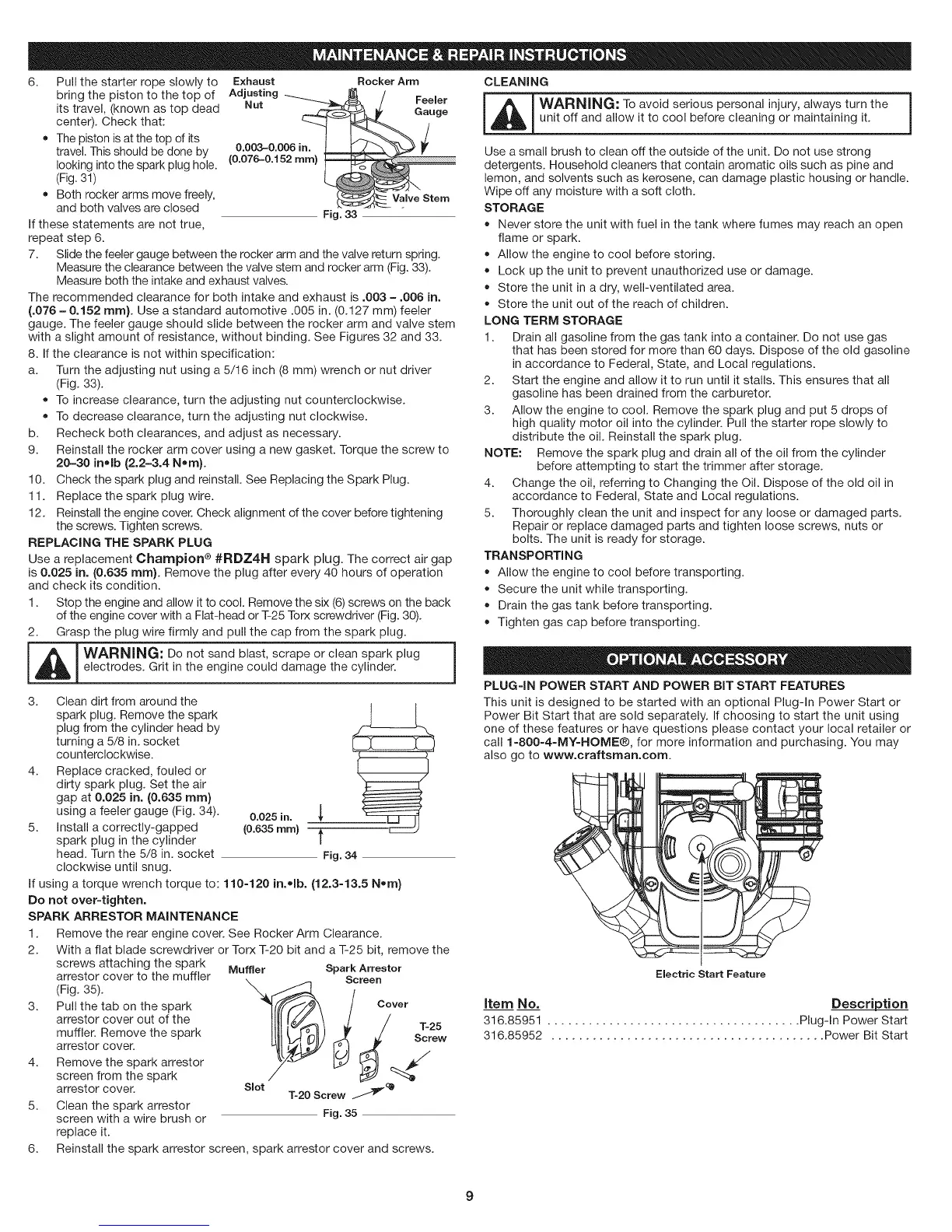

4. Replace cracked, fouled or

dirty spark plug. Set the air

gap at 0.025 in. (0.635 rnrn)

using a feeler gauge (Fig. 34). 0.025 in.

5. Install a correctly-gapped (0.635ram) t

spark plug in the cylinder

head. Turn the 5/8 in. socket Fig. 34

clockwise until snug.

If using a torque wrench torque to: 110=120 in.=ib. (12.3=13.5 N,rn)

Do not over=tighten.

SPARK ARRESTOR MAINTENANCE

1. Remove the rear engine cover. See Rocker Arm Clearance.

2. With a flat blade screwdriver or Torx T-20 bit and a T-25 bit, remove the

screws attaching the spark Muffler Spark Arrestor

arrestor cover to the muffler Screen

tFi035/ /

3. Pull the tab on the spark Cover

arrestor cover out of the 1"-25

muffler. Remove the spark ._ Screw

arresto r cover.

4. Remove the spark arrestor _) _::_/"

screen from the spark

arrestor cover, slot T-20 Screw ._ "lv'q_

5. Clean the spark arrestor

screen with a wire brush or Fig. 35

replace it.

6. Reinstall the spark arrestor screen, spark arrestor cover and screws.

CLEANING

_[_ ARNING: To avoid serious personal injury, always turn the

unit off and allow it to cool before cleaning or maintaining it.

Use a small brush to clean off the outside of the unit. Do not use strong

detergents. Household cleaners that contain aromatic oils such as pine and

lemon, and solvents such as kerosene, can damage plastic housing or handle.

Wipe off any moisture with a soft cloth.

STORAGE

• Never store the unit with fuel in the tank where fumes may reach an open

flame or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

LONG TERM STORAGE

1. Drain all gasoline from the gas tank into a container. Do not use gas

that has been stored for more than 60 days. Dispose of the old gasoline

in accordance to Federal, State, and Local regulations.

2. Start the engine and allow it to run until it stalls. This ensures that all

gasoline has been drained from the carburetor.

3. Allow the engine to cool. Remove the spark plug and put 5 drops of

high quality motor oil into the cylinder. Pull the starter rope slowly to

distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil from the cylinder

before attempting to start the trimmer after storage.

4. Change the oil, referring to Changing the Oil. Dispose of the old oil in

accordance to Federal, State and Local regulations.

5. Thoroughly clean the unit and inspect for any loose or damaged parts.

Repair or replace damaged parts and tighten loose screws, nuts or

bolts. The unit is ready for storage.

TRANSPORTING

• Allow the engine to cool before transporting.

• Secure the unit while transporting.

• Drain the gas tank before transporting.

• Tighten gas cap before transporting.

PLUG=IN POWER START AND POWER BIT START FEATURES

This unit is designed to be started with an optional Plug-In Power Start or

Power Bit Start that are sold separately. If choosing to start the unit using

one of these features or have questions please contact your local retailer or

call 1=800=4=MY=HOME®, for more information and purchasing. You may

also go to www.craftsrnan.com.

Electric Start Feature

Item No. Description

316.85951 ..................................... Plug-In Power Start

316.85952 ........................................ Power Bit Start

9

Loading...

Loading...