8

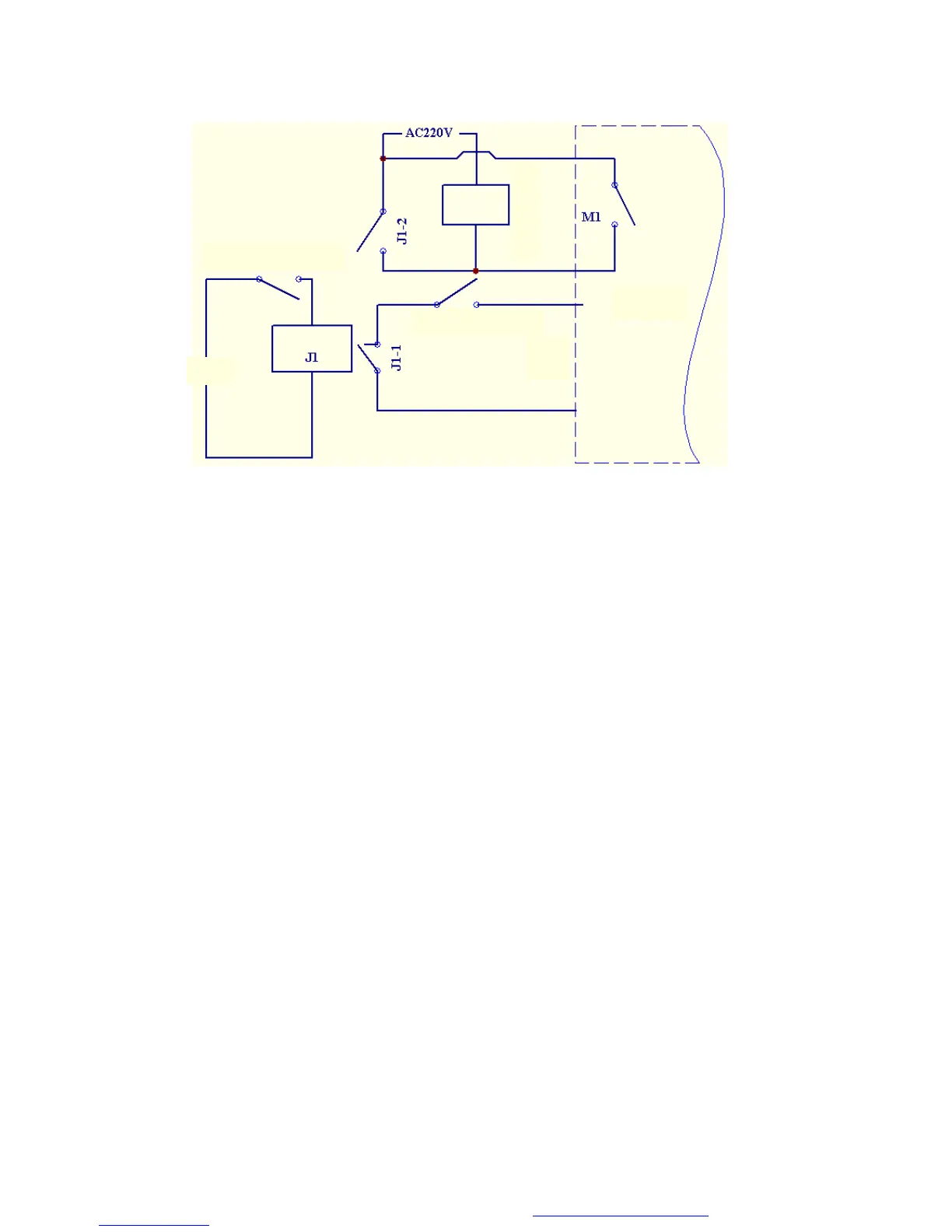

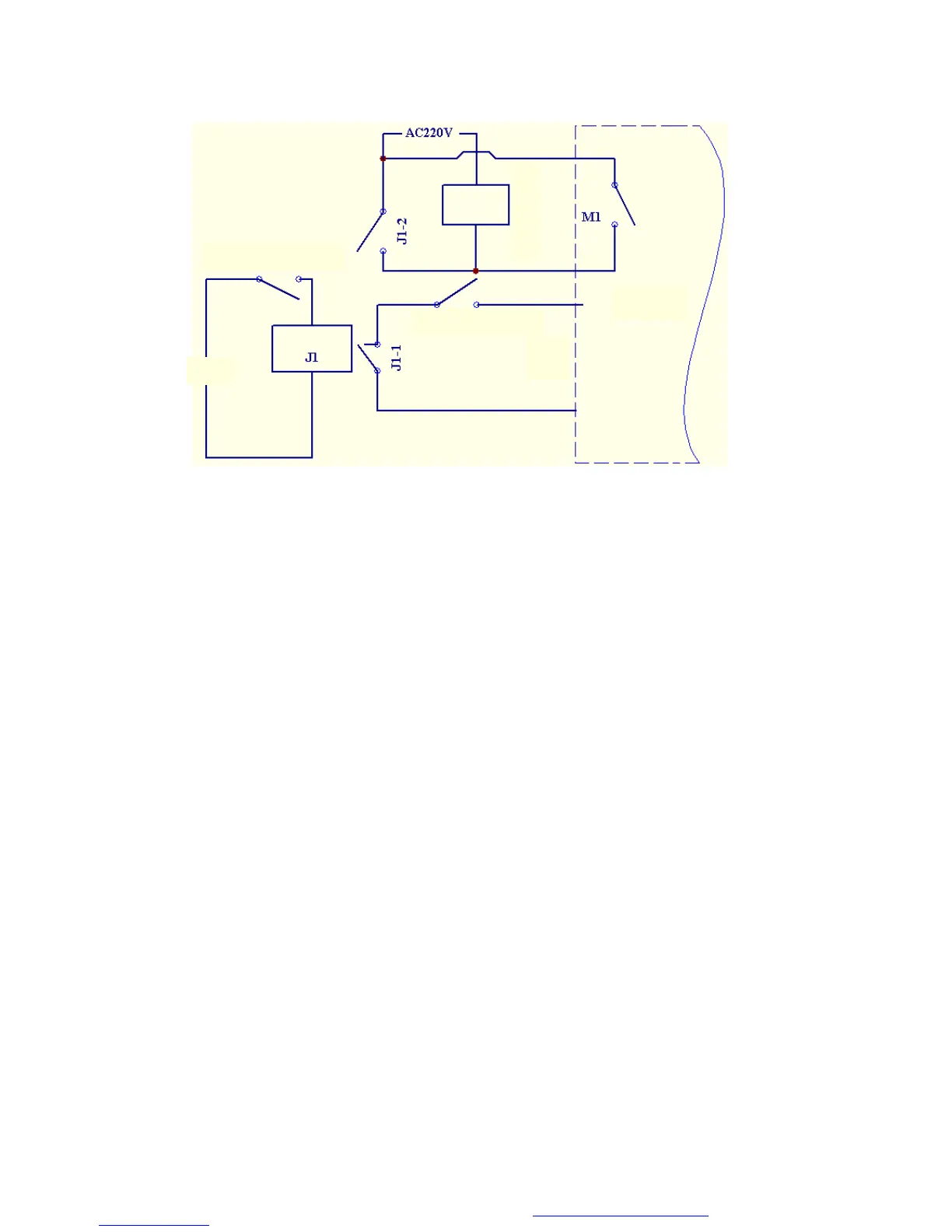

8 Connection for automatic reverse flushing:

Relay J1 should be added for reverse flushing. Two contacting points J1-1,J1-2 is normally open and

close .J1 is controlled by pretreatment timer and time of reverse flushing is subject to close time of

normally open contacting point.

9 Measurement electrode (CELL) installation

To ensure the real measurement result, data distortion caused by air bubble or dead water in

conductance cell should be avoided. The installation should be performed strictly according to the

following drawing:

Notes: (1) The electrode should be installed at a lower location in the pipe where the flow speed is steady

and air bubbles are seldom generated.

(2) No matter the conductance cell is horizontally or vertically installed, it should be deeply

inserted into the moving water.

(3) The conductivity signal is weak electronic signal and its collecting cable should be separately

installed. They should not be connected to the same group of cable joint or terminal board with

the power line.

(4) When the measurement cable needs to be lengthened, it’s recommended to use the cable provided

by the original manufacturer, When a longer distance is involved, the length of the cable

(<30m) should be agreed on before delivery, and if the length is over 30m, a transmitter should

be used.

10 Maintenance

(1) The conductance cell, as a sophisticated component, can not be disassembled. Unless necessary the

electrode cell should not be taken out of measurement cell .Conductance cell should be cleaned

regularly for keeping surface clean. when the electrode platinum black coating is dirty, soak it in 10%

dilute hydrochloric acid for two minutes , then rinse it with pure water to keep the surface clean.

(2) The measurement cable is special cable and should not be changed at will or it will cause significant

error.

(4)The special auxiliary electrode cell should be used in case of damage .

Pre-processing normally open contact

Loading...

Loading...