English

7

English

8

Figure 3

Figure 4

Figure 5

Allow the angle grinder to run in idle for at least a minute with the grinding or cutting

disc correctly assembled, vibration disc should be immediately replaced.

3.Operation

Switch Action (

CT13300 CT13301 CT13115)

1)When starting hold the tool firmly with both hands i.e. One hand on the rear handle

and the other on the side handle.

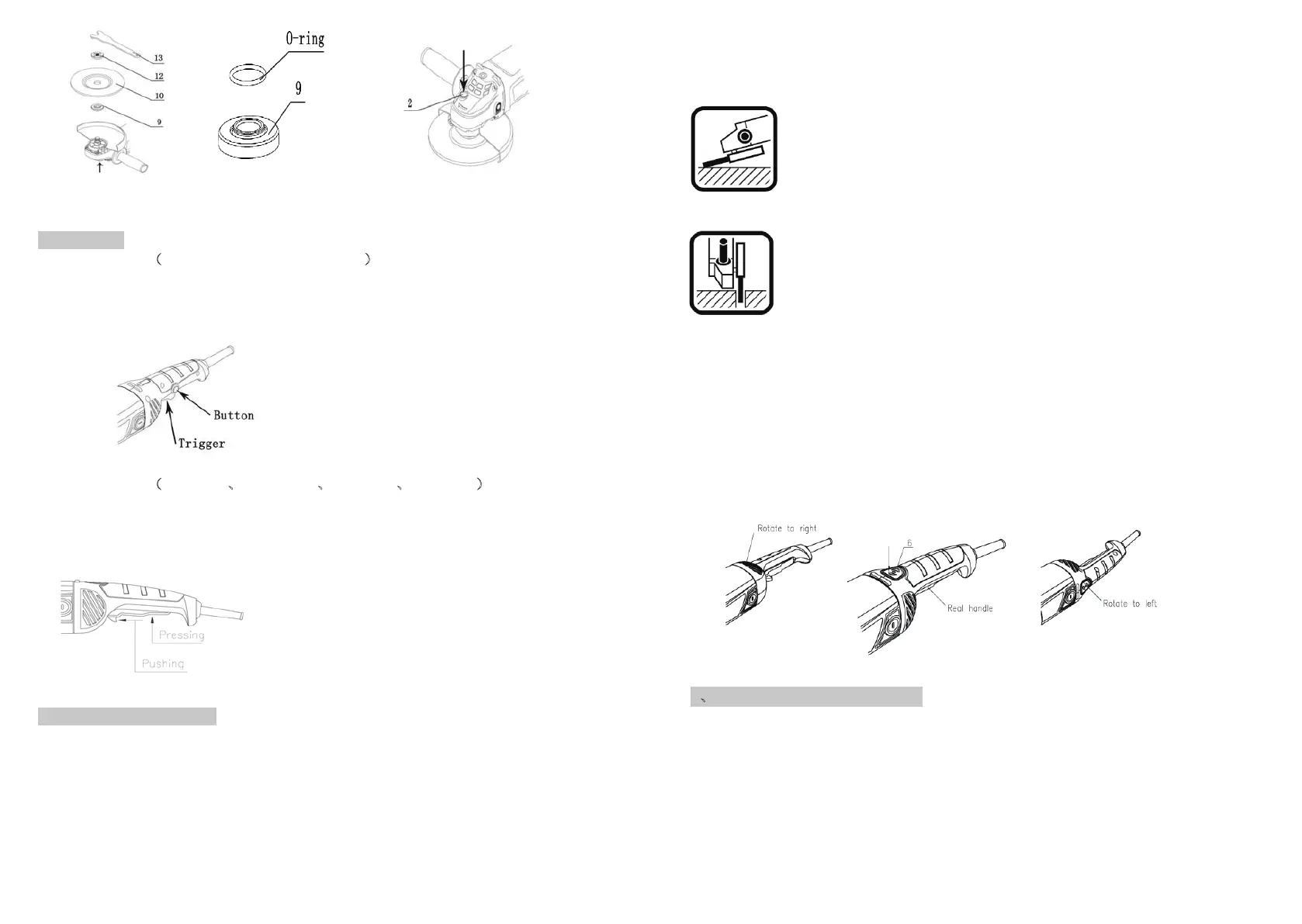

2)Start the tool by pressing the button of on/off switch, then pressing the trigger of

on/off switch down slightly.(See figure 6)

Figure 6

3)Stop the tool by releasing the trigger of switch.

Switch Action (

CT13303、CT13287S、CT13287、CT13070)

1)When starting hold the tool firmly with both hands i.e. One hand on the rear handle

or motor housing and the other on the side handle.

2)Start the tool by pushing forward on the switch, then pressing the trigger of switch

down slightly.(figure 7)

Figure 7

3)Stop the tool by releasing the trigger of switch.

4.Operating instructions

Note: This angle grinder can be used for grinding and cutting steel , stone or ceramic

workpieces such as pipe, box section, rectangular, angle iron steel bar, house bricks

and tiles. Do not attempt to grind wood or a soft metal such as lead. The material will

quickly “fill” the disc and render it useless.

Before starting the grinder first ensure that the disc、 disc guard and tool are in good

condition. Position the guard so that it will deflect hot sparks away from the operator.

1)Do not cover exhaust vents when the tool is in use. This may cause damage to the

motor and reduce the efficiency of the tool.

2)Guide back and forth over the work piece in a steady motion.

3)To cut hard stone a diamond cutting wheel is recommended.

Grinding

The best results are achieved with an angle of 30

to 40

for grinding.

Move the machine back and forth with light pressure. In this manner,

the workpiece does not become too hot, no discoloration occurs and

no ridges are produced.

Under no circumstances should a cutting disc be used for roughing

work.

Cutting

When cutting, do not press, tilt or oscillate. Work with a moderate

feed rate that is suited to the material to be worked.

The direction in which one cuts is important.

The machine must always rotate opposite to the direction of motion;

therefore never move the machine in the other direction. Otherwise,

the danger exists that it will be forced uncontrolled out of the cut.

When cutting profiles or square pipes, it is best to start with the smallest cross

section.

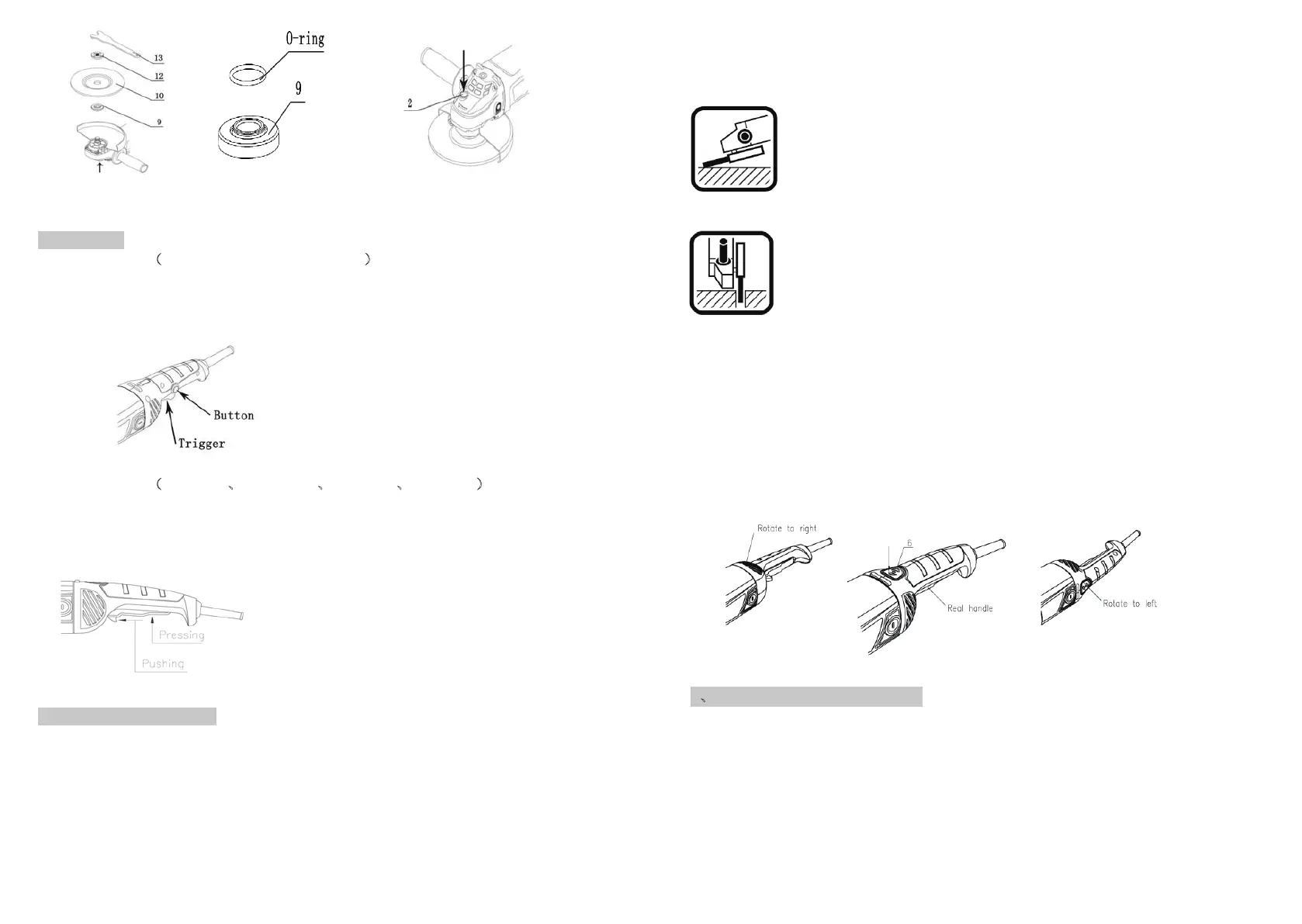

1)To rotate the rear handle press on the rotating release button (6) and move the

handle to one of the present positions.

Note: The rear handle can be rotated to the left or right. It must be “Locked” into one

of the three preset positions: central, 90°to the left or 90°to the right. It must not be

used at any position in between these three preset positions as it might rotate during

us

e and create a hazard.(Figure 8)

Figure 8

5、Maintenance and inspection

CAUTION: Always be sure that the tool is switched off and unplugged before

attempting to perform inspection or maintenance.

1)The armature and stator(motor) is the heart of the power tool. Exercise due care to

ensure they do not become damaged or affected by oil or water.

2)The carbon brushes should be checked periodically and worn-out brushes should

be replaced in time. After replacing, inspect whether the new carbon brushes can

move freely in the brush bolder. Keep running the motor for 15 minutes to match the

contact of the carbon brushes and commutator.

Loading...

Loading...