Operation

7-8

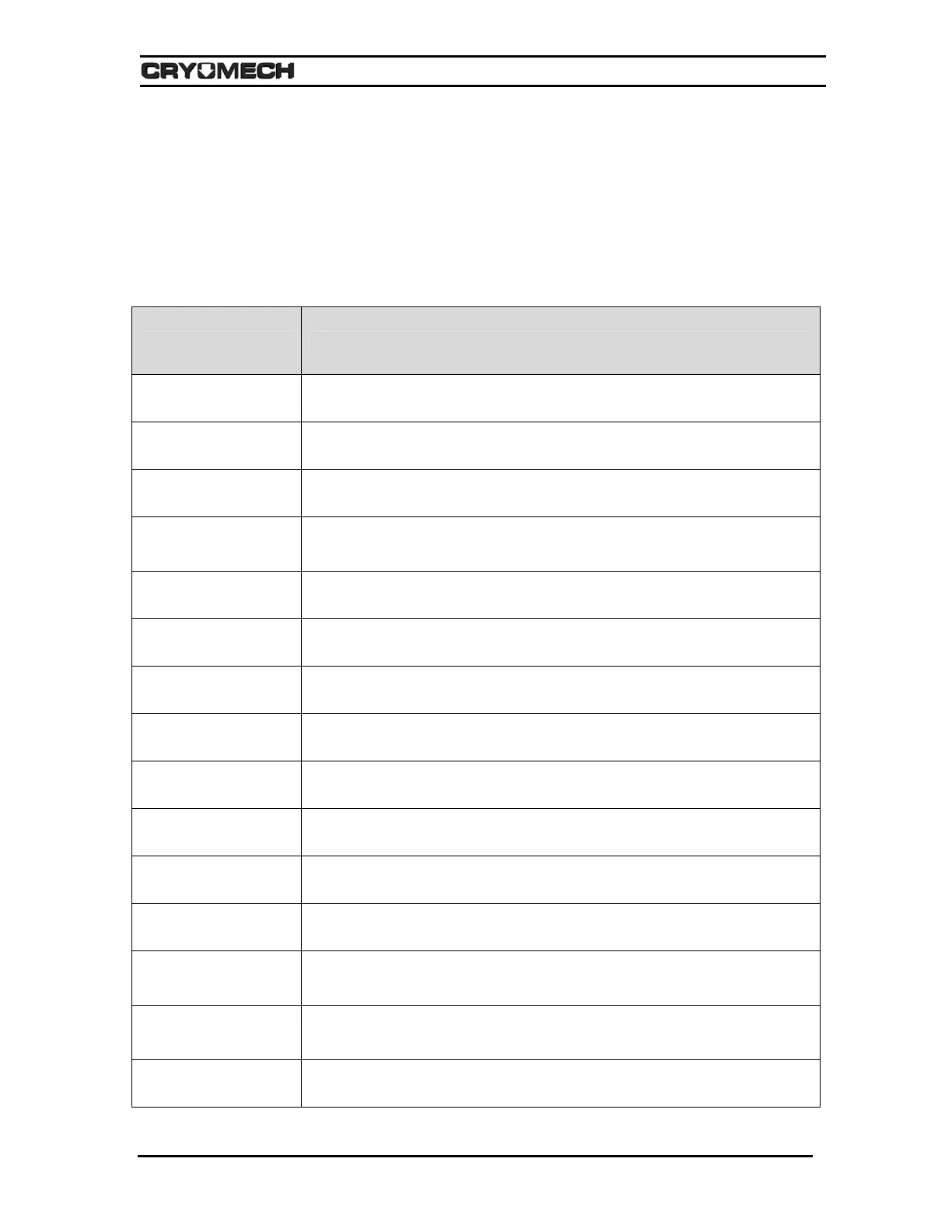

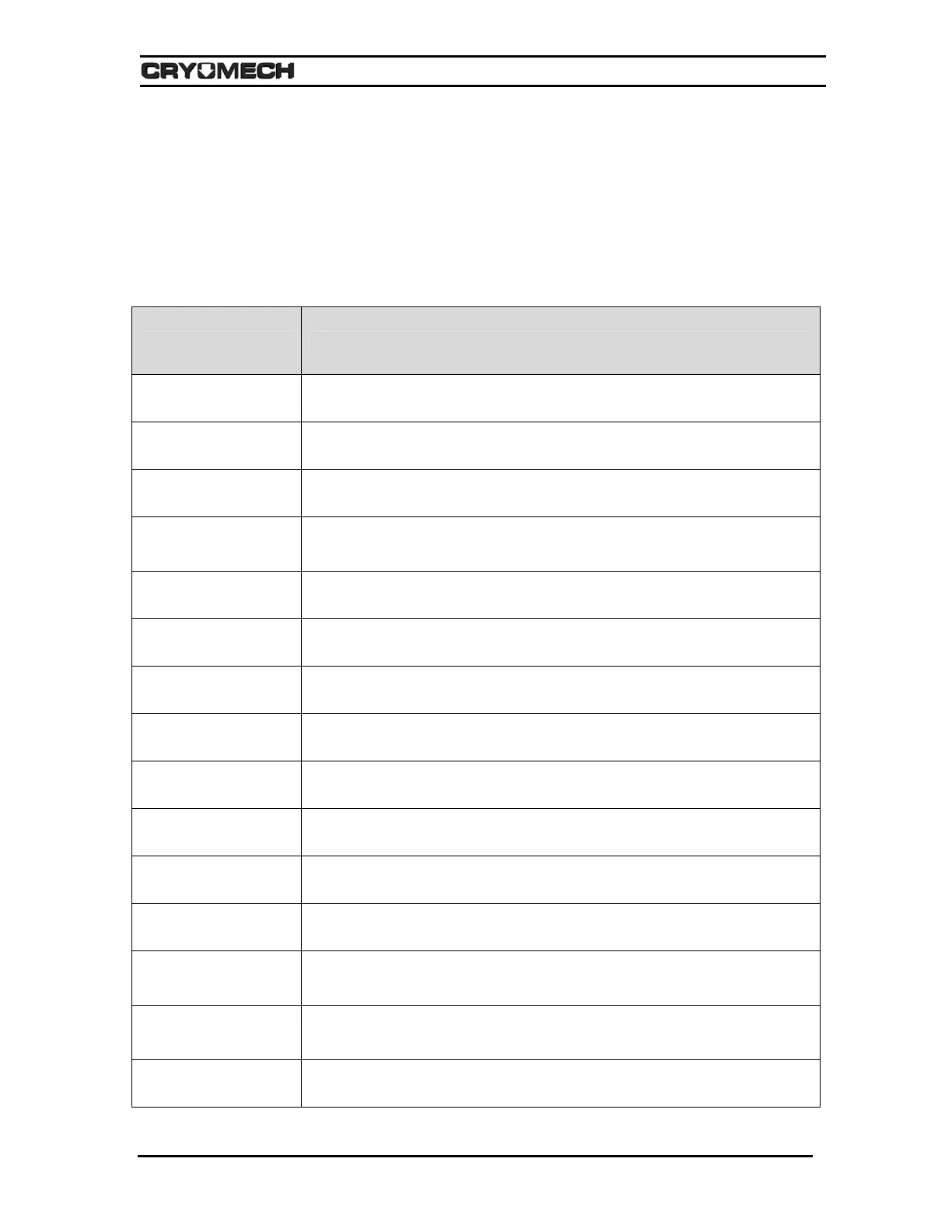

7.7.5 Error diagnostics on display screen

Errors will cause the compressor system to stop. Errors are displayed on the bottom line

of the display screen. If more than one of the errors below is present, only the highest

priority one will be displayed. The table lists errors from highest to lowest priority. If the

error is a lockout contributor, it will be noted in the Explanation column.

Once the error condition has cleared, the compressor can be restarted by pressing the

Compressor ON button.

If the error condition still exists the compressor will not restart.

Error Message Explanation

"High pressure too

High!"

The high side pressure is above the high set point. Release helium from

the system.

"High pressure too

Low!"

The high side helium below the low set point. Add helium to the system.

“Low Pressure Too

Low!”

The helium gas pressure is below the threshold. Add helium to the

system.

“Low Pressure Too

High!"

The low side helium pressure is above the high set point; release helium

from the system, verify line orientation (lines may be reversed High to

Low.)

"Delta Pressure Too

High!"

The differential pressure is above the high set point; verify static

pressure.

"Delta Pressure Too

Low!"

The differential pressure is below the low set point verify static pressure;

verify line orientation (lines may be reversed High to Low.)

"Static Pressure Too

High!"

The static pressure is above the high set point; verify static pressure,

release helium

"Static Pressure Too

Low!"

The static pressure is below the low set point; verify static pressure, add

helium

"Water In Temp Too

High"

The inlet water temperature is above the high set point; reduce water

temperature

"Water In Temp Too

Low"

The inlet water temperature is below the low set point; increase water

temperature

“Water Out Temp Too

High!”

The outlet water temperature is above the high set point; increase water

flow rate and/or reduce temperature.

"Water Out Temp Too

Low"

The outlet water temperature is below the low set point; increase water

temperature.

“Helium Temp Too

High!”

The helium gas temperature is above the high set point; check cooling

water flow rate/temperature, check compressor module oil level by

checking sight glass when the compressor is running.

“Helium Temp Too

Low!"

Helium discharge temperature below the low set point; check cooling

water temperatures, increase ambient temperature if system has been

off and ambient temperature is below 40°F

“Oil Temp Too High!”

The oil temperature is above the high set point; Check flow rate and

inlet temperature of cooling water.

Loading...

Loading...