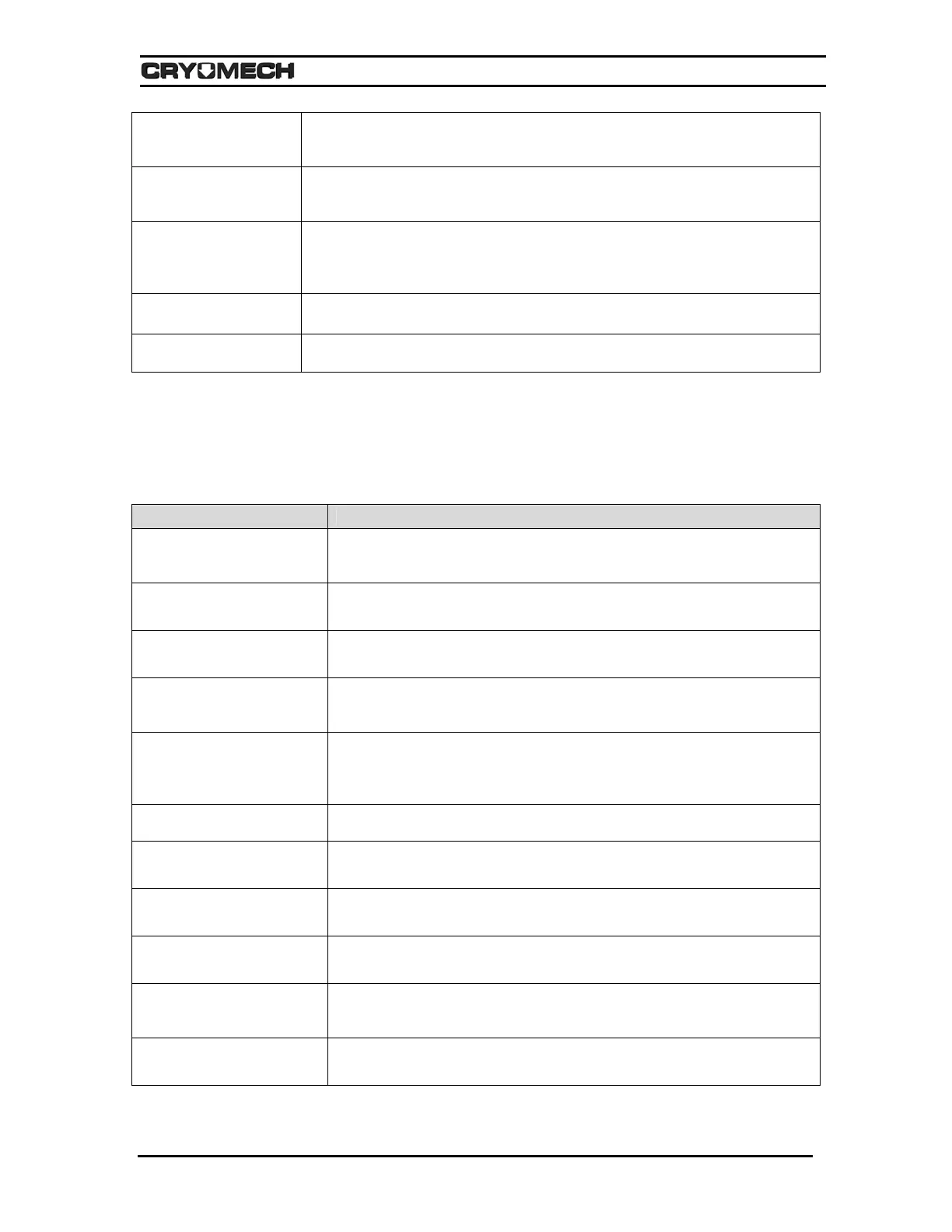

Operation

7-9

“Oil Temp Too Low!" The oil temperature is below the low set point; check cooling water

temperatures, increase ambient temperature if system has been off and

ambient temperature is below 40°F

“Compressor Motor

Current Too Low!”

This occurs when the compressor module motor current is below

threshold while the motor is requested running. Can be caused by an

overheated compressor module.

“You have had 6

errors in less than an

hour: MM:SS”

The compressor is in lockout mode due to more than 6 errors within one

hour; the compressor cannot be started until 30 minutes has elapsed,

and the lockout has been reset using the reset button. MM:SS indicates

minutes : seconds remaining until compressor can be restarted

“3 Phase Power

Improperly Wired!”

The order of the phase power is wrong. Re-wire the input to the

compressor by switching any 2 of the 3 input power wires.

"Power Supply Error!"

Power supply has exhibited a fault, verify voltage output or contact

Cryomech

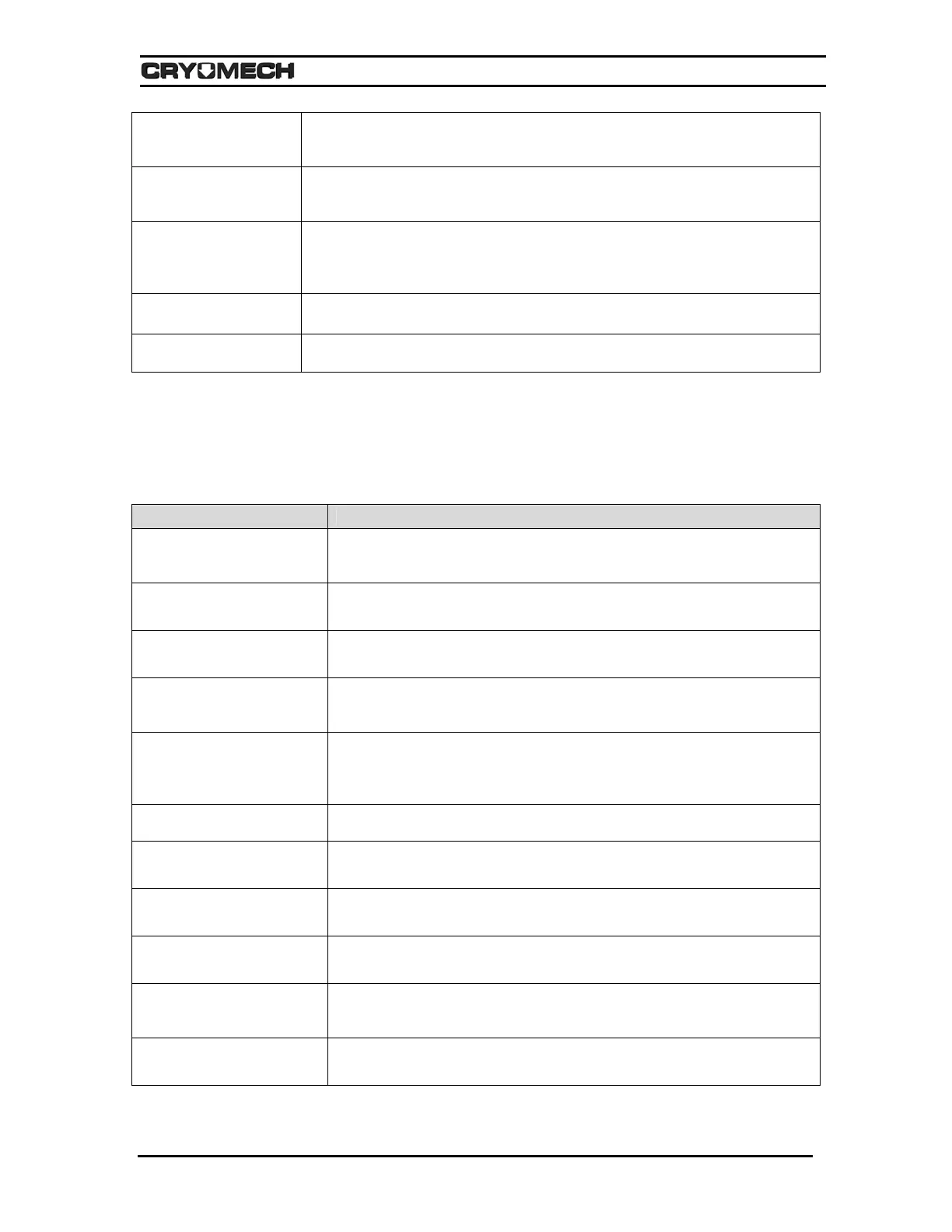

7.7.6 Warning diagnostics on display screen

Warnings do not cause the compressor to stop and do not prevent the compressor from

starting. If more than one of the warnings below is present, only the highest priority one

will be displayed.

Warning Description Explanation

"High Pressure Running

High!"

High pressure is approaching high set point, if the warning does not

go away after the cold head cools down, verify that static pressures

are correct and all lines are connected completely.

"High Pressure Running

Low!"

High pressure is approaching the low set point; verify static pressure,

check historical data to determine if a leak may have occurred.

“Low Pressure Running

Low!”

Low pressure is approaching the low set point; verify static pressure,

check historical data to determine if a leak may have occurred.

“Low Pressure Running

High!"

Low pressure is approaching the high set point; Flex lines may be

reversed check orientation of lines, verify that the high pressure is

greater than the low pressure

"Delta Pressure Running

High!"

Differential pressure approaching high set point; this condition may

occur on initial startup. Under normal operation it will reduce as the

cold head begins to cool down. If not check static pressure and flex

line connections

"Delta Pressure Running

Low!"

Differential pressure approaching low error set point; flex lines may

be reversed

"Static Pressure Running

High!"

Static pressure approaching high error set point; verify required

static pressure before starting the compressor

"Static Pressure Running

Low!"

Static pressure approaching low error set point; verify required static

pressure before starting the compressor

"Water In Temp Running

High"

Water inlet temperature is approaching high error set point; reduce

inlet water temperature or increase flow rate to prevent overheating

"Water In Temp Running

Low"

Water inlet temperature is approaching low error set point; increase

inlet water temperature or reduce flow rate to prevent overcooling or

overheating caused by reduced oil temperature

“Water Out Temp

Running High!”

Water outlet temperature is approaching high error set point; reduce

inlet water temperature or increase flow rate to prevent overheating

Loading...

Loading...