Maintenance Guide CCP800 series

5

Maintenance Guide CCP800 series

4

3 CCP800 series Trolley & Ancillaries Maintenance

3.1 Trolley Power

3.2 Bluetooth Oil Temp Probe

Always return the probe back to the holster

when not in use. Failure to follow this

process may lead to poor charge in the

batteries and not enough to complete a test.

3.3 Oil Temp Probe Length

Always adjust the probe to the correct length

prior to starting a test, it should be 10mm

shorter than the dipstick.

Failure to follow this process may cause not

only probe but engine damage.

3.4 RPM Device (Battery Tach)

To minimise the risk of unstable readings

load the battery by turning on headlights,

fog lights etc. Keep the cabin fan o as this

may introduce interference. Some modern

vehicles may not be detected due to “smart

charging systems” cutting the charge when

the battery does not require it. This is not a

fault with the equipment.

Daily

At the end of the day shut down the PC

and then turn the power o using the

switch on the side of the trolley leaving

the unit plugged in and switched on at the

mains. Failure to follow this process may

lead to poor charge in the batteries and

not enough to complete a test.

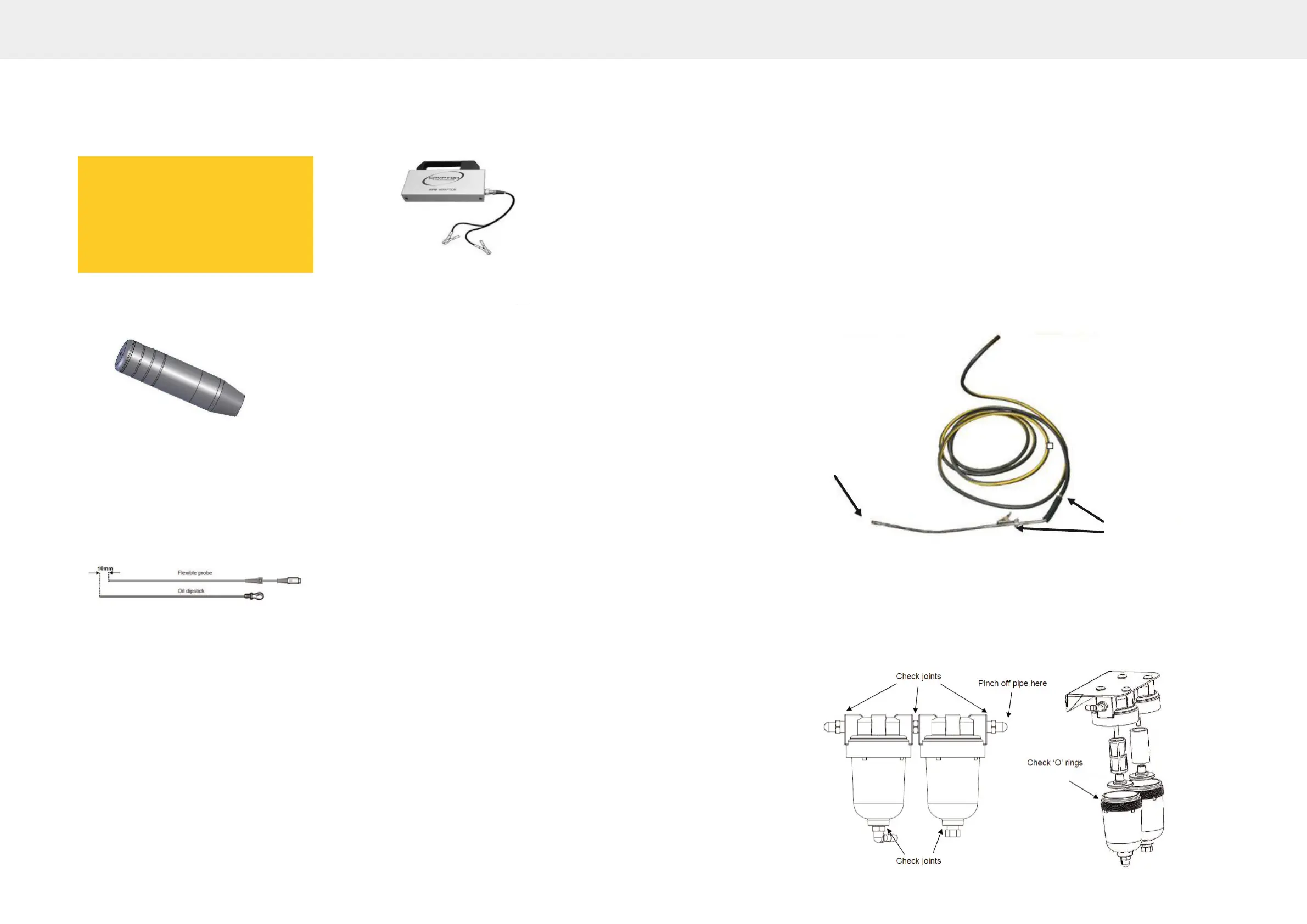

■ If the test still fails, ‘pinch o’ the pipe immediately after the gas lter bowl (see Fig 3.

overleaf) and retest.

■ If problem cured, check all joints on sample inlet and lter bowl assembly, particularly the

bowl to bowl adapter.

■ Unscrew lter bowls and ensure the 'O' rings are in good condition and have not been

'pinched' during assembly.

4 Vehicle Exhaust Gas Analyser (VEGA) Fault Finding

4.1 Leak Test Failure

The system is drawing in air, possible causes of a leak test failure are faulty joints, particularly in

sample probe/hose assembly and between the two lter bowls. Damaged 'O' ring seals of lter

bowls, particularly if lters have just been changed.

4.2 Checks

■ Pump operation - Is the pump running?

■ Disconnect sample hose from the gas analyser

■ Block the sample inlet and re-test

■ If problem cured, inspect joints for leaks/damage

■ Ensure exible probe is not damaged

■ In cases of extreme exhaust gas temperature the PTFE liner may melt and cause leak test

failure

Check exible P.T.F.E liner

inside braiding. Replace the

exible probe end if

necessary.

Check joints

4.3 Sample probe/hose assembly

Fig. 3

Loading...

Loading...