2.1 Clean Optics

Do not use chemical based cleaning products

on the optics

2.2 Smoke Head Cable (cable

version)

Always return to the cradle when not in use.

2.3 Clean Charging Pins

(Bluetooth Version)

Always return to the cradle when not in use.

2.4 Sample Pipe

Weekly

Clean the charging pins at least once a

week to avoid corrosion. If unmaintained

you may have communication issues

and/or early life battery failure.

Daily

Ensure cable is kept clean and unkinked.

Failure to maintain may cause

communication problems.

Monthly

Remove dirt from the lens with a clean

cloth or alcohol wipe. If unmaintained this

may cause zero drift issues. More detail

available in the operators manual.

Maintenance Guide CCP800 series

2

Maintenance Guide CCP800 series

3

1 Vehicle Exhaust Gas Analyser (VEGA) Maintenance

1.1 Water Trap

Do not use any chemical based products to

clean the water trap. Soapy water and gently

airline.

1.2 Sample Probe

Do not use any chemical based products to

clean the water trap. Soapy water and gently

airline.

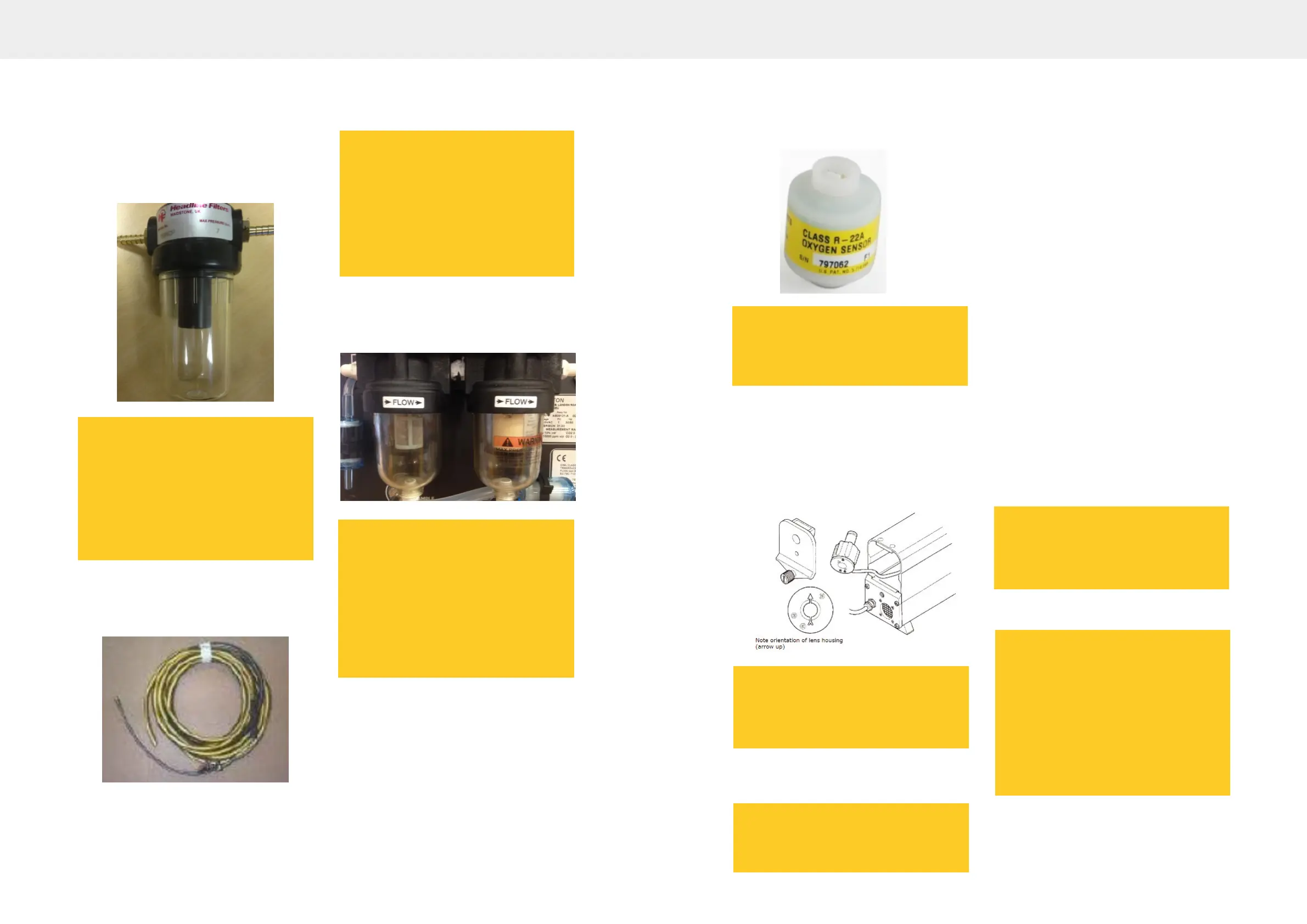

1.3 Filter Bowls

Do not use any Chemical based products to

clean the water trap. Soapy water and gently

airline.

Daily

Check pipe and probe tip for damage.

Gently with an airline blow down the

probe to remove any blockages or

moisture. Don’t leave the sample hoses

on the workshop oor when not in use,

always return them to the trolley. I f

unmaintained this may cause low ow

errors, leak test failures and/or terminal

gas bench errors.

2 Diesel Smoke Meter (DSM) Maintenance

Daily

Remove any moisture from the water trap

and check that the ‘o’ rings are not

damaged or pinched.

Add a small amount of inert silicone

petroleum jelly around the top of the

water trap where the o ring sits. This may

cause terminal gas bench failure and

possible low ow issues if maintenance is

not carried out correctly.

Weekly

Remove excess moisture from all lter

bowls (Replace lter weekly if required)

and check that the o rings are not

damaged or pinched. Add a small amount

of inert silicone petroleum jelly around the

top of the water trap where the o ring sits

to help create a seal. This may cause

terminal gas bench failure and possible

low ow or contamination issues if

maintenance is not carried out correctly.

Annually

O2 sensor will need to be checked and/or

replaced every 6 - 12 months depending

on your usage. It is recommended that

you keep a spare available on site.

As required

Under normal circumstances the sampling

head does not require cleaning. If a

sampling pipe becomes restricted with

deposits, the test results can be aected.

To clean a sampling pipe, remove the

sample probe from the smoke head. Blow

through the sample pipe only, using

compressed air.

DO NOT BLOW THROUGH THE

SMOKEHEAD.

1.4 O2 Sensor

Loading...

Loading...