PART NO. MS0070

>

REvISION 3

>

JULY 2017 V2

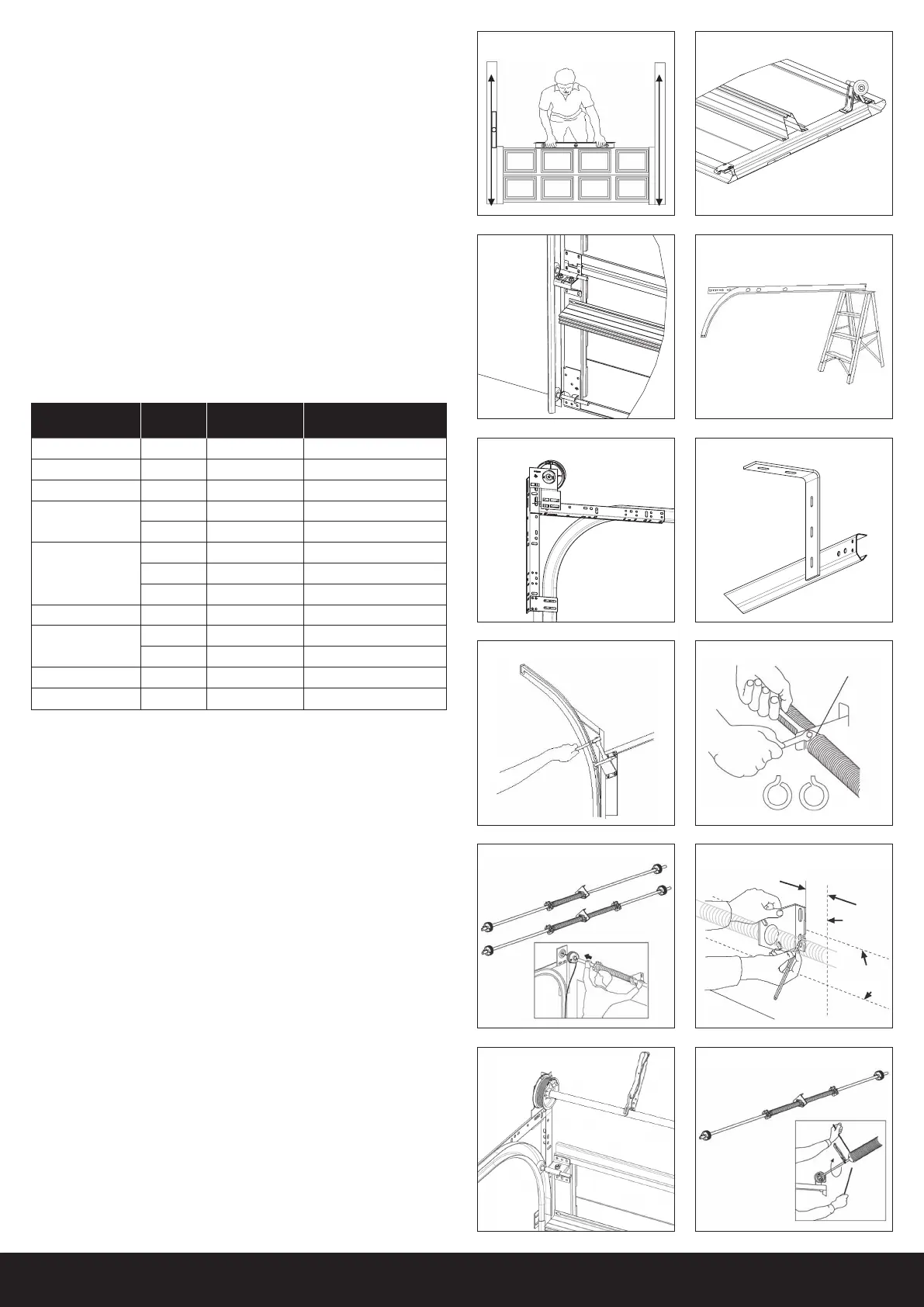

STE P 11

Secure the rear of the horizontal track with steel angle brackets supplied, if

not suitable it will be necessary to fabricate from other material. Make sure

that the track is level and square with the opening. Due to the fact that the

horizontal tracks are weight bearing, when the door is fully opened ensure

that adequate fasteners are used into solid fixings (FIGURE 12). Repeat this

step for the second horizontal track.

STEP 12

Fit the top panel by removing the sliding section from each top hangar and

placing the panel in position with cardboard between the joint to the panel

below, refit the sliding section with the axle into the track fit bolts and nuts

do not tighten, fit fixings to the hinge below.

The sliding section on the top door panel bracket should be loose. Push

roller to the front of the front of the guide and adjust top panel leaving

enough clearance between head and jamb. Once satisfied that the roller is

correctly positioned in the track then tighten the slide bracket (FIGURE 13).

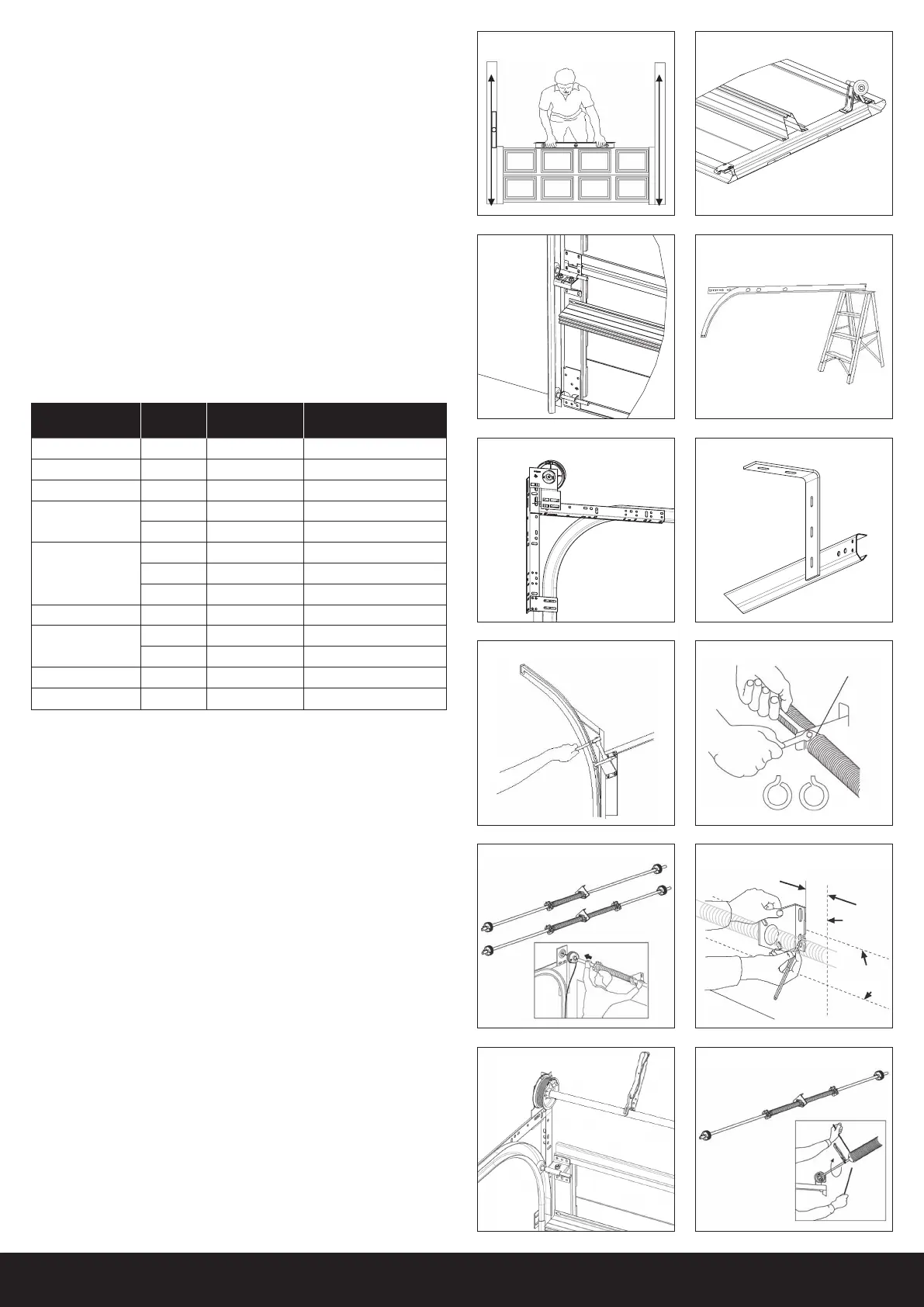

REINFORCING BRACING

STEP 13

These are placed as follows:

When fixing reinforcing ensure 2 fixing are placed at each end and to every

intermediate stile (FIGURE 8).

SPRING AND SHAFT ASSEMBLY

STEP 14

Attach the bearing plate to each horizontal angle on both tracks using

carriage bolts and nuts (FIGURE 11).

STEP 15

Secure the spring anchor plugs to the centre bearing. Locate the left wound

spring to the right side of the plate and the right wound spring to the left of

the plate. If your door only requires one wound spring locate it to the left or

right as detailed above. Slide the completed spring assembly over the shaft

and slide into place the cable drums at each end. Ensure that the correct

drums are on the right ends as marked (FIGURE 14 and 15 also ATTENTION

INSTALLERS diagram on following page).

STEP 16

Place the shaft assembly over the horizontal tracks and slide one end

through the bearing plate with the greatest side clearance, then insert the

opposite end into its bearing plate (FIGURE 15).

STEP 17

Take hold of the spring bearing plate and raise it until the shaft is level.

Position the bracket near the centre of the header so that the opener can be

fixed in the centre and securely fix to the wall (FIGURE 16).

STEP 18

Pull the cables up in the space between the tracks and the door. Align the

cable over the back of the cable drum and insert in the cable slot. Lay the

cable over the highest outside groove of the drum and tighten cable drum

onto the shaft place a clamp onto the shaft and against the lintel to prevent

the cable unwinding (FIGURE 17). Repeat for the second cable and drum

making sure both cables and drums are evenly aligned.

FIGURE 13

FIGURE 10

FIGURE 12

FIGURE 8

FIGURE 14 Two spring arrangement

Left

wound

spring

Right

wound

spring

Spring

Anchor

Plug

L.W.S R.W.S

FIGURE 15

FIGURE 17

FIGURE 16

FIGURE 18

Guide only

2100mm high

- approx 7.5 turns

2400mm high

- approx 8.5 turns

+/- 75mm

Door

centre

line

Centre line

between bearing

holes

Line B

FIGURE 9

FIGURE 7

DOOR WIDTH

PANEL

QTY

REO QTY FIT TO

0 - 3,570mm 4-6 0 n/a

3,575 - 4,600mm 4-6 1 top

4,605 - 4,900mm 4-6 2 top + bottom

4,905 - 5,250mm

4 2 top + bottom

5-6 3 top + bottom + middle

5,255 - 5,510mm

4 2 top + bottom

5 3 top + bottom + middle

6 5 miss the middle panel

5,515 - 5,930mm 4-5 3 top + bottom + middle

5,935 - 6,100mm

4 3 top + bottom + middle

5 4 miss the middle panel

5,515 - 6,100mm 6 6 all the panels

6,105 - 6,500mm 4-6 reo all panels

all the panels

FIGURE 11

Loading...

Loading...