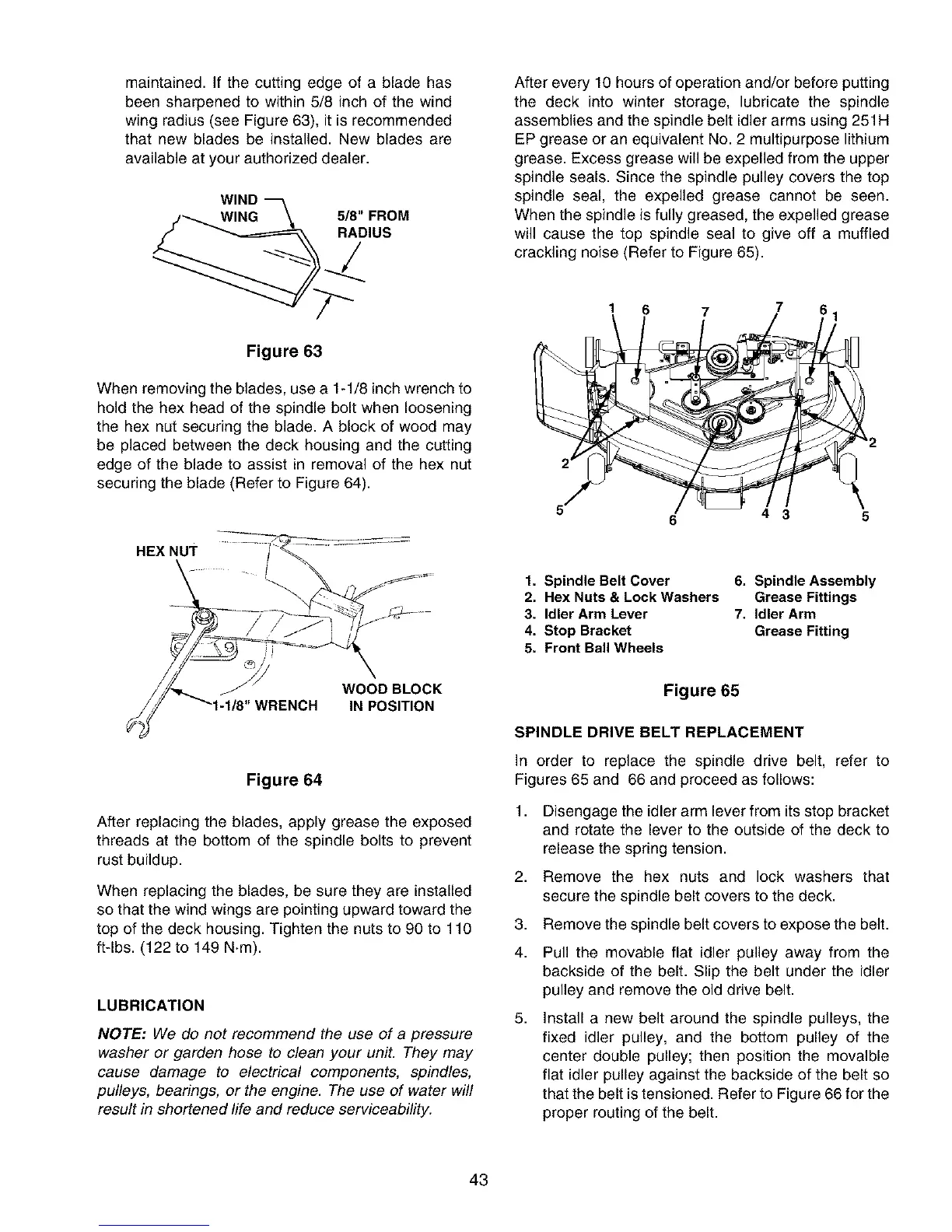

maintained. If the cutting edge of a blade has

been sharpened to within 5/8 inch of the wind

wing radius (see Figure 63), it is recommended

that new blades be installed. New blades are

available at your authorized dealer.

WIND

WING 5/8" FROM

RADIUS

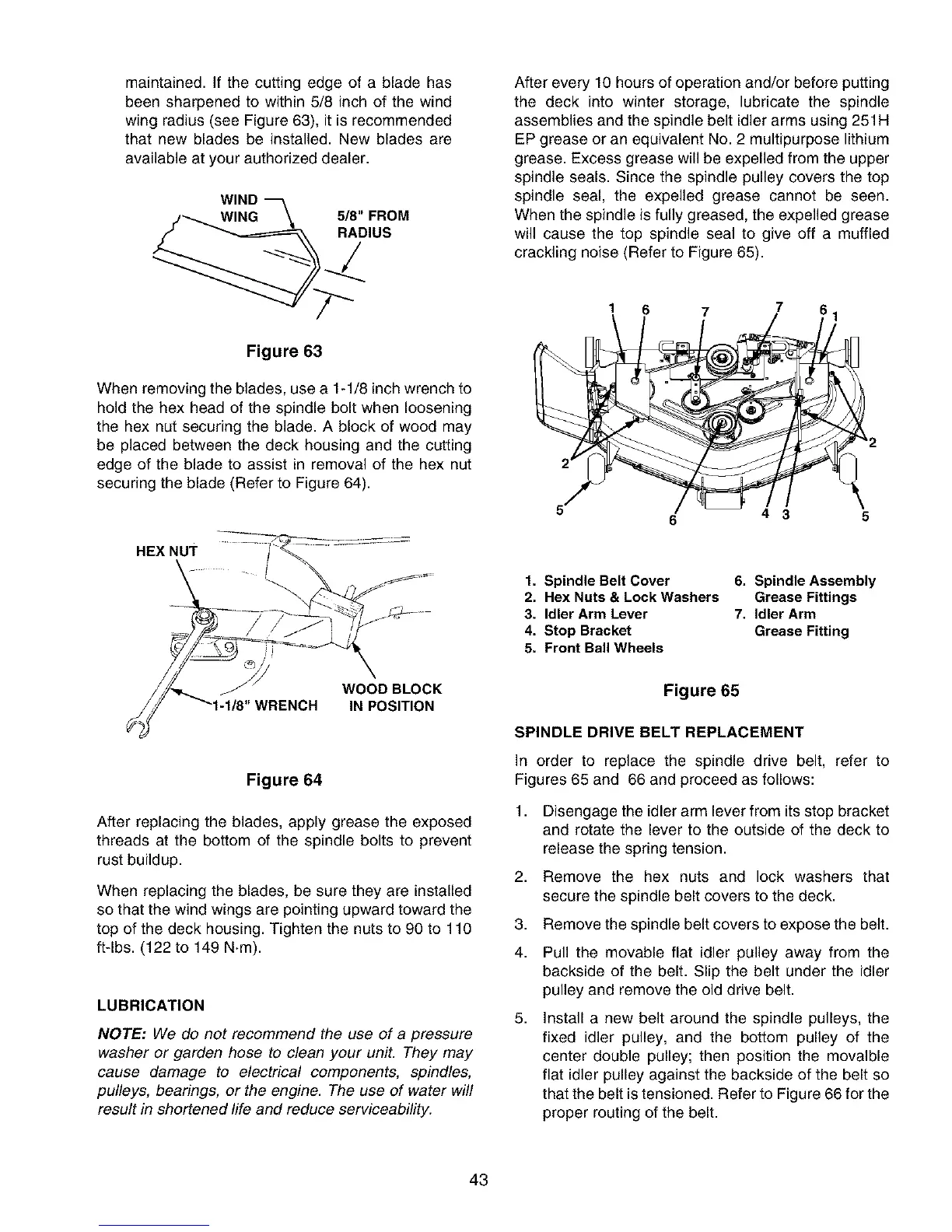

After every 10 hours of operation and/or before putting

the deck into winter storage, lubricate the spindle

assemblies and the spindle belt idler arms using 251H

EP grease or an equivalent No. 2 multipurpose lithium

grease. Excess grease will be expelled from the upper

spindle seals. Since the spindle pulley covers the top

spindle seal, the expelled grease cannot be seen.

When the spindle is fully greased, the expelled grease

will cause the top spindle seal to give off a muffled

crackling noise (Refer to Figure 65).

Figure 63

When removing the blades, use a 1-1/8 inch wrench to

hold the hex head of the spindle bolt when loosening

the hex nut securing the blade. A block of wood may

be placed between the deck housing and the cutting

edge of the blade to assist in removal of the hex nut

securing the blade (Refer to Figure 64).

HEX NUT

1 6

'2

1. Spindle Belt Cover

2. Hex Nuts & Lock Washers

3. Idler Arm Lever

4. Stop Bracket

5. Front Ball Wheels

6. Spindle Assembly

Grease Fittings

7. Idler Arm

Grease Fitting

WOOD BLOCK

1/8"WRENCH IN POSITION

Figure 64

After replacing the blades, apply grease the exposed

threads at the bottom of the spindle bolts to prevent

rust buildup.

When replacing the blades, be sure they are installed

so that the wind wings are pointing upward toward the

top of the deck housing. Tighten the nuts to 90 to 110

ft-lbs. (122 to 149 N.m).

LUBRICATION

NOTE: We de not recommend the use of a pressure

washer or garden hose to clean your unit. They may

cause damage to electrical components, spindles,

pulleys, bearings, or the engine. The use of water will

result in shortened life and reduce serviceability.

Figure 65

SPINDLE DRIVE BELT REPLACEMENT

In order to replace the spindle drive belt, refer to

Figures 65 and 66 and proceed as follows:

1. Disengage the idler arm lever from its stop bracket

and rotate the lever to the outside of the deck to

release the spring tension.

2. Remove the hex nuts and lock washers that

secure the spindle belt covers to the deck.

3. Remove the spindle belt covers to expose the belt.

4. Pull the movable flat idler pulley away from the

backside of the belt. Slip the belt under the idler

pulley and remove the old drive belt.

5,

Install a new belt around the spindle pulleys, the

fixed idler pulley, and the bottom pulley of the

center double pulley; then position the movalble

flat idler pulley against the backside of the belt so

that the belt is tensioned. Refer to Figure 66 for the

proper routing of the belt.

43

Loading...

Loading...