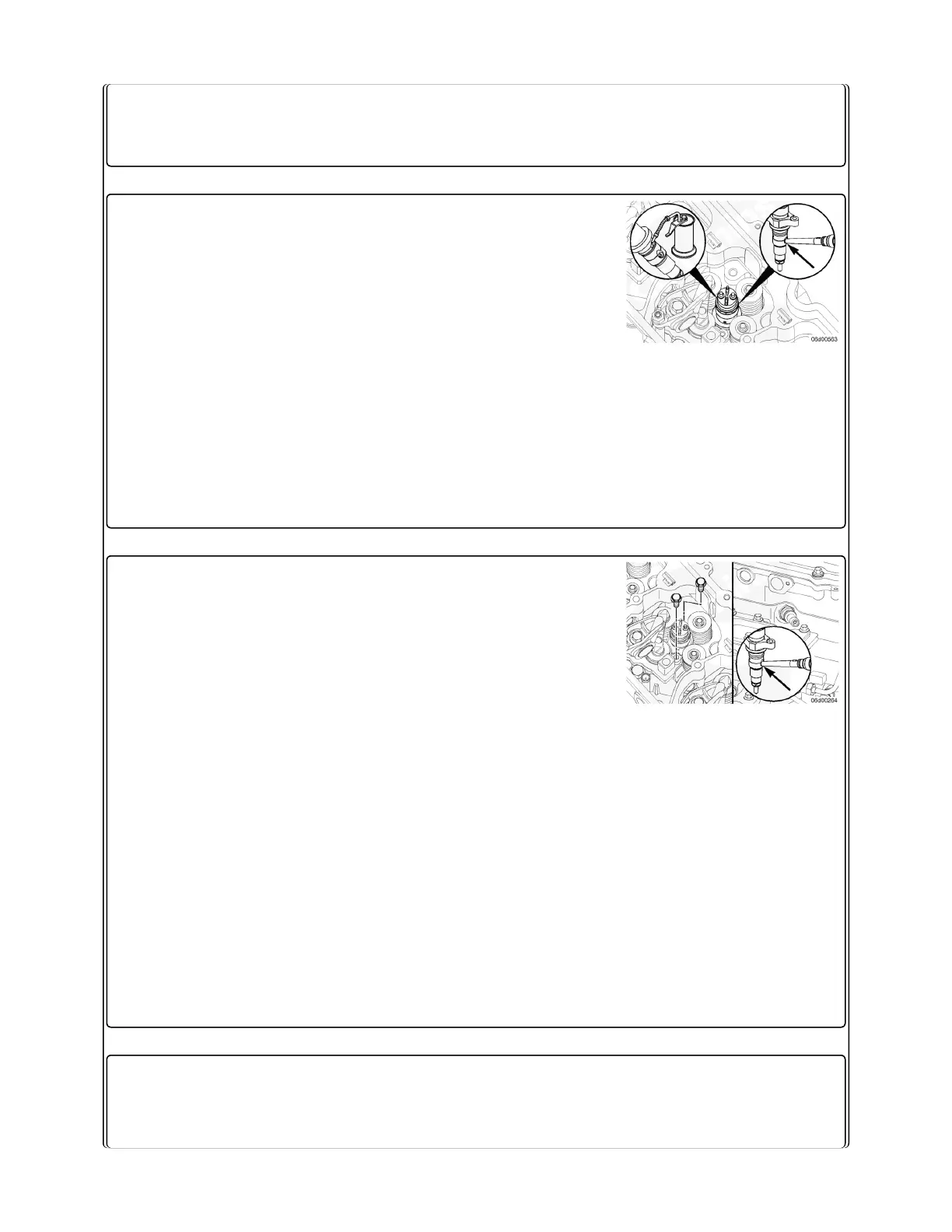

Note: The injector trim codes are nine character

alphanumeric codes located on the solenoid at the

top of the injector.

Note: If a new injector is being installed, a new

fuel connector must be used.

Make sure the injector bore is clean and that only one

(1) sealing washer is installed on the injector nozzle.

Lubricate the injector o-ring with clean engine oil.

Place the injector in the cylinder head in the proper

orientation (fuel inlet toward the high-pressure fuel

connector).

Press down firmly on the injector to make sure it is

seated in the injector bore.

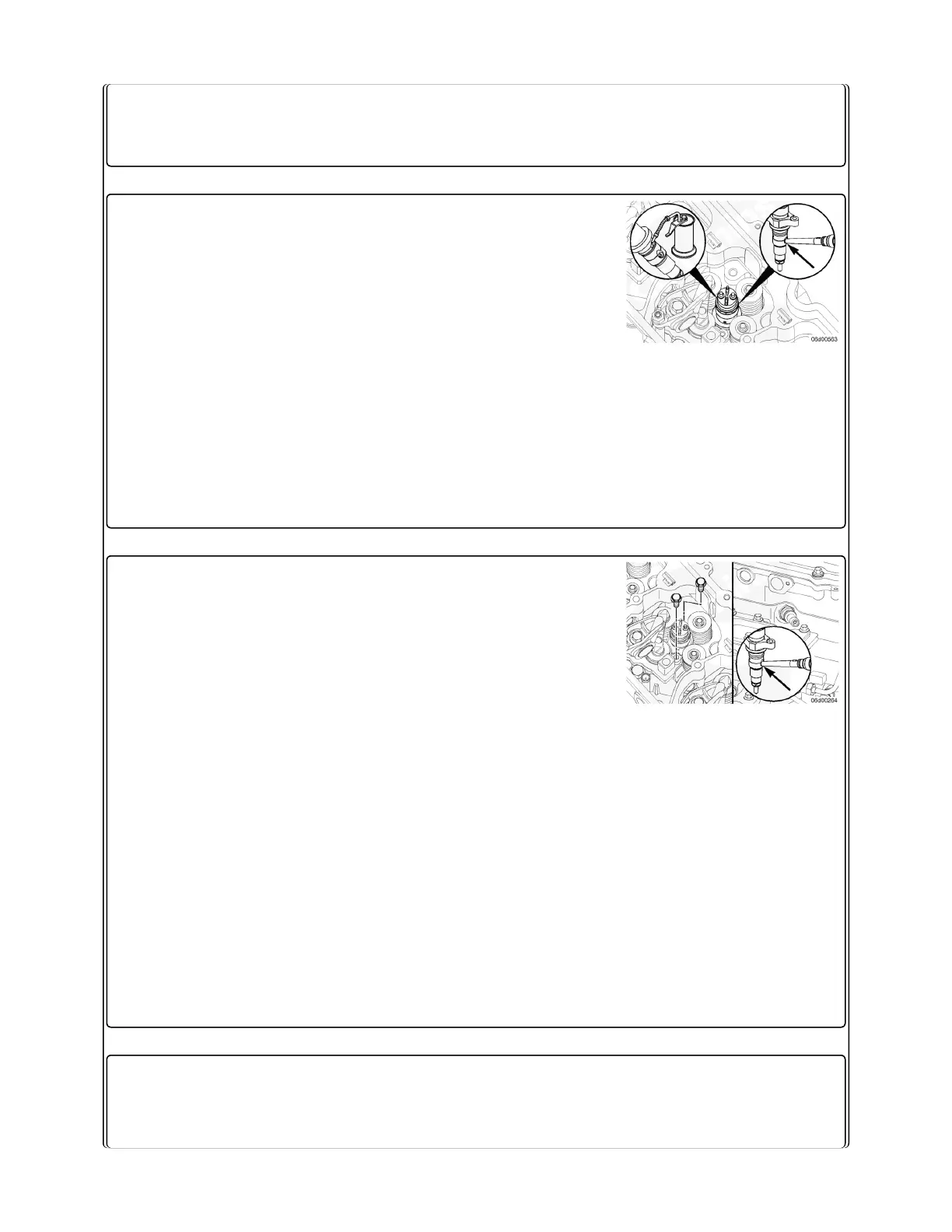

Note: Start the injector hold-down clamp

capscrews, but do not tighten.

Start the injector hold-down clamp capscrews, and

tighten hand-tight.

Install the high-pressure fuel connector, making sure the

end of the high-pressure fuel connector is in the injector

inlet port.

Note: The high-pressure fuel connector should

click into place if it is seated in the injector inlet

port correctly.

Start the high-pressure fuel connector retaining nut and

tighten partially.

TorqueValue: 15 n•m [ 133 in-lb ]

Note: This is not the final torque for the high-

pressure fuel connector retaining nut.

Tighten the injector hold-down clamp capscrews.

Note: Make sure to tighten the hold-down clamp

capscrews evenly. Check to make sure the gap

Loading...

Loading...