5 Piping installation

Installation manual

16

2MXM-A, 3MXM-A, 4MXM-A, 5MXM-A

R32 Split series

3P600450-6R – 2022.05

Outdoor unit Total indoor unit capacity

class

4MXM80 ≤14.5kW

5MXM90 ≤15.6kW

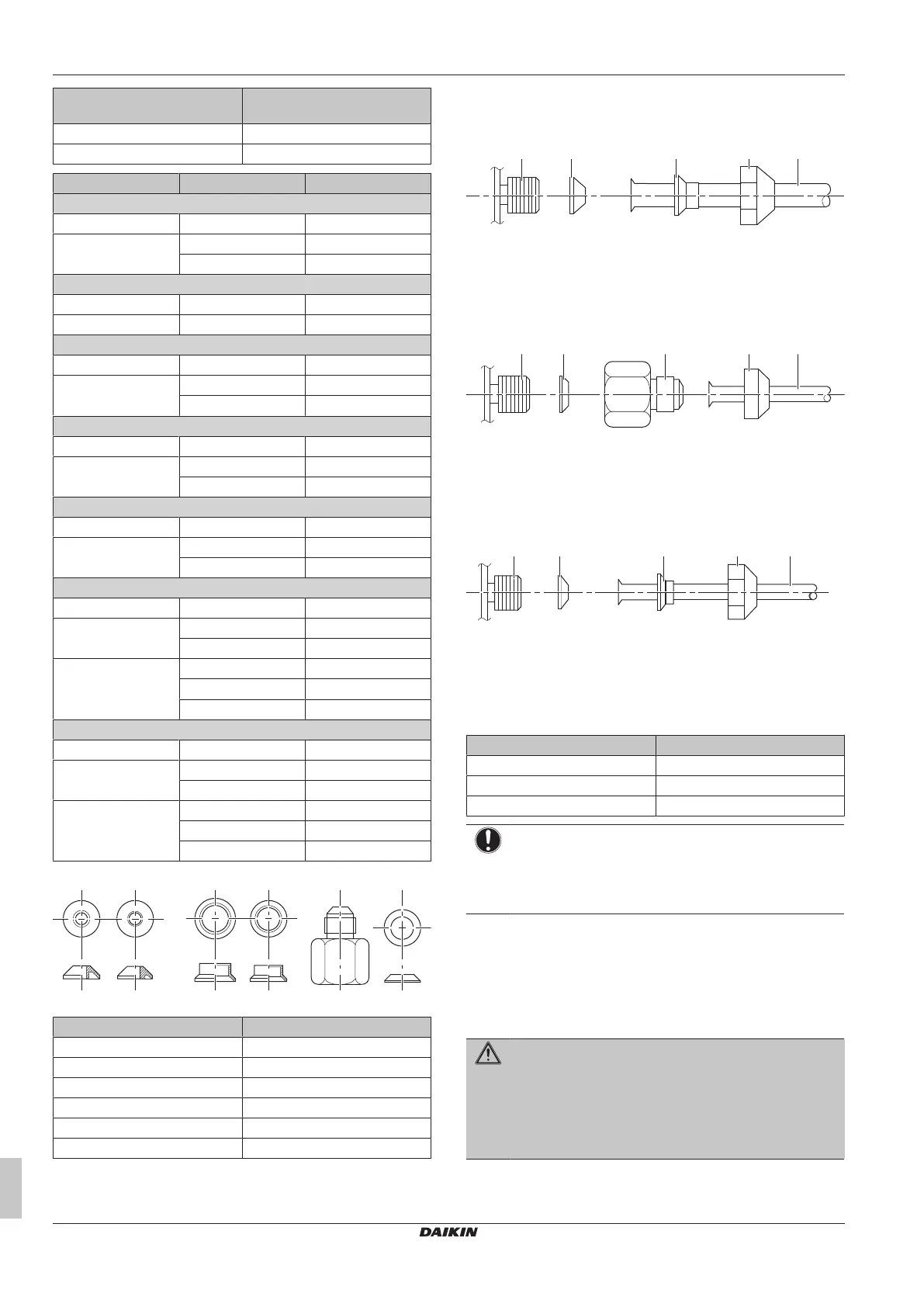

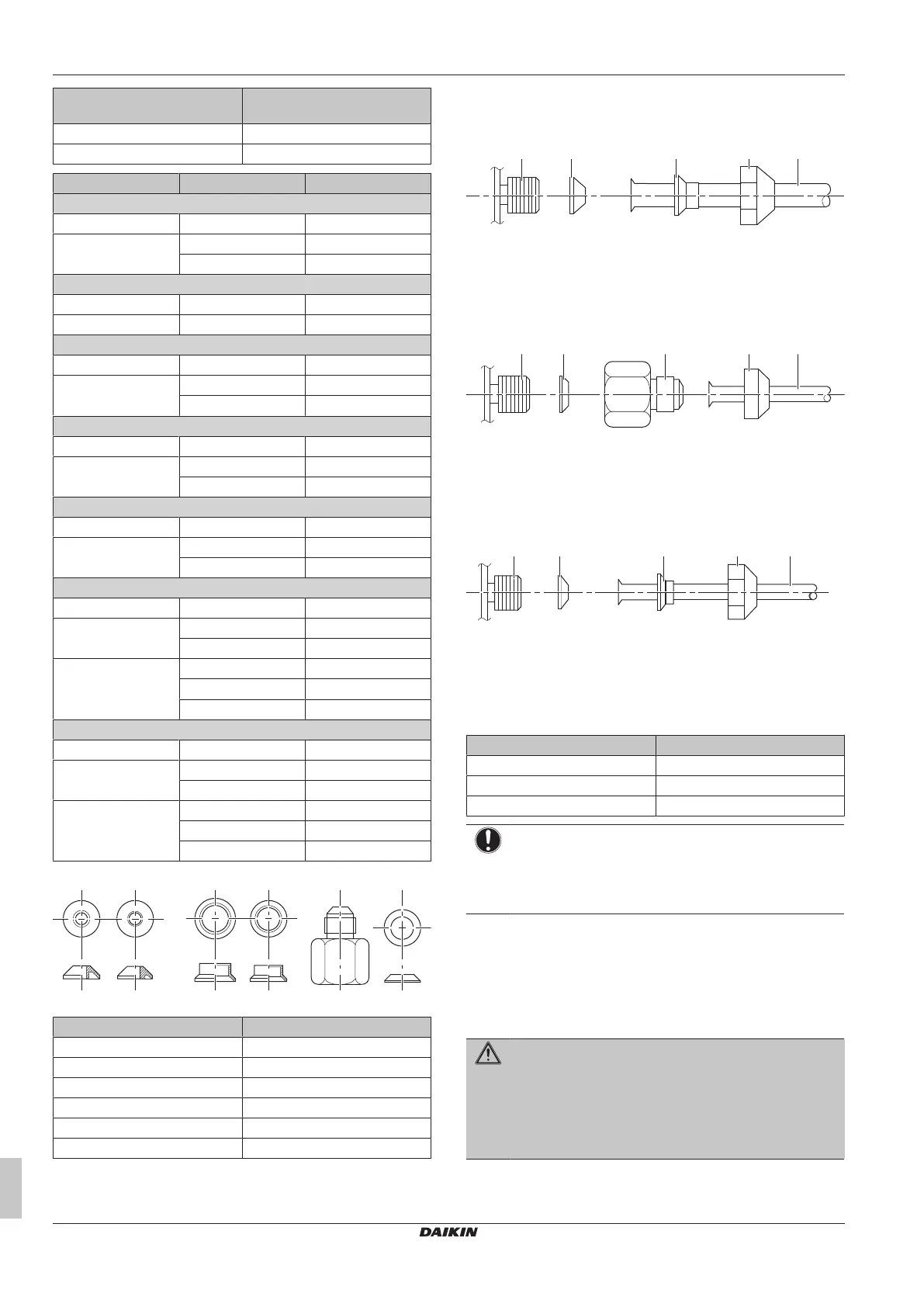

Port Class Reducer

2MXM68

A (Ø9.5mm) 15, 20, 25, 35, (42)

(a)

—

B (Ø12.7mm) 15, 20, 25, 35, (42)

(a)

2+4

42, 50, 60 —

3MXM40

A (Ø9.5mm) 15, 20, 25, 35 —

B + C (Ø12.7mm) 15, 20, 25, 35 2+4

3MXM52

A (Ø9.5mm) 15, 20, 25, 35, (42)

(a)

—

B + C (Ø12.7mm) 15, 20, 25, 35 2+4

42, 50 —

3MXM68

A (Ø9.5mm) 15, 20, 25, 35, (42)

(a)

—

B + C (Ø12.7mm) 15, 20, 25, 35, 42 2+4

50, 60 —

4MXM68

A + B (Ø9.5mm) 15, 20, 25, 35, (42)

(a)

—

C + D (Ø12.7mm) 15, 20, 25, 35, (42)

(a)

2+4

42, 50, 60 —

4MXM80

A (Ø9.5mm) 15, 20, 25, 35, (42)

(a)

—

B (Ø12.7mm) 15, 20, 25, 35, (42)

(a)

2+4

42, 50, 60 —

C + D (Ø15.9mm) 15, 20, 25, 35, (42)

(a)

5+6

42, 50, 60 1+3

71 —

5MXM90

A + B (Ø9.5mm) 15, 20, 25, 35, (42)

(a)

—

C (Ø12.7mm) 15, 20, 25, 35, (42)

(a)

2+4

42, 50, 60 —

D + E (Ø15.9mm) 15, 20, 25, 35, (42)

(a)

5+6

42, 50, 60 1+3

71 —

(a)

Only in case of connection with FTXM42R.

Reducer type Connection

1 Ø15.9mm → Ø12.7mm

2 Ø12.7mm → Ø9.5mm

3 Ø15.9mm → Ø12.7mm

4 Ø12.7mm → Ø9.5mm

5 Ø15.9mm → Ø9.5mm

6 Ø15.9mm → Ø9.5mm

Connection examples:

▪ Connecting a Ø12.7mm pipe to a Ø15.9mm gas pipe connection

port

a Outdoor unit connection port

b Reducer no. 1

c Reducer no. 3

d Flare nut for Ø15.9mm

e Inter-unit piping

▪ Connecting a Ø9.5mm pipe to a Ø15.9mm gas pipe connection

port

a Outdoor unit connection port

b Reducer no. 6

c Reducer no. 5

d Flare nut for Ø9.5mm

e Inter-unit piping

▪ Connecting a Ø9.5mm pipe to a Ø12.7mm gas pipe connection

port

a Outdoor unit connection port

b Reducer no. 2

c Reducer no. 4

d Flare nut for Ø12.7mm

e Inter-unit piping

Coat the threaded connection port of the outdoor unit where the flare

nut comes in with refrigeration oil.

Flare nut for (mm) Tightening torque (N•m)

Ø9.5 33~39

Ø12.7 50~60

Ø15.9 62~75

NOTICE

Use an appropriate wrench to avoid damaging the

connection thread by overtightening the flare nut. Be

careful NOT to overtighten the nut, or the smaller pipe may

be damaged (about 2/3-1× the normal torque).

5.2.2 To connect the refrigerant piping to the

outdoor unit

▪ Piping length. Keep field piping as short as possible.

▪ Piping protection. Protect the field piping against physical

damage.

WARNING

Connect the refrigerant piping securely before running the

compressor. If the refrigerant piping is NOT connected and

the stop valve is open when the compressor is run, air will

be sucked in. This will cause abnormal pressure in the

refrigeration cycle, which may result in equipment damage

and even injury.

1 Connect the liquid refrigerant connection from the indoor unit to

the liquid stop valve of the outdoor unit.

Loading...

Loading...