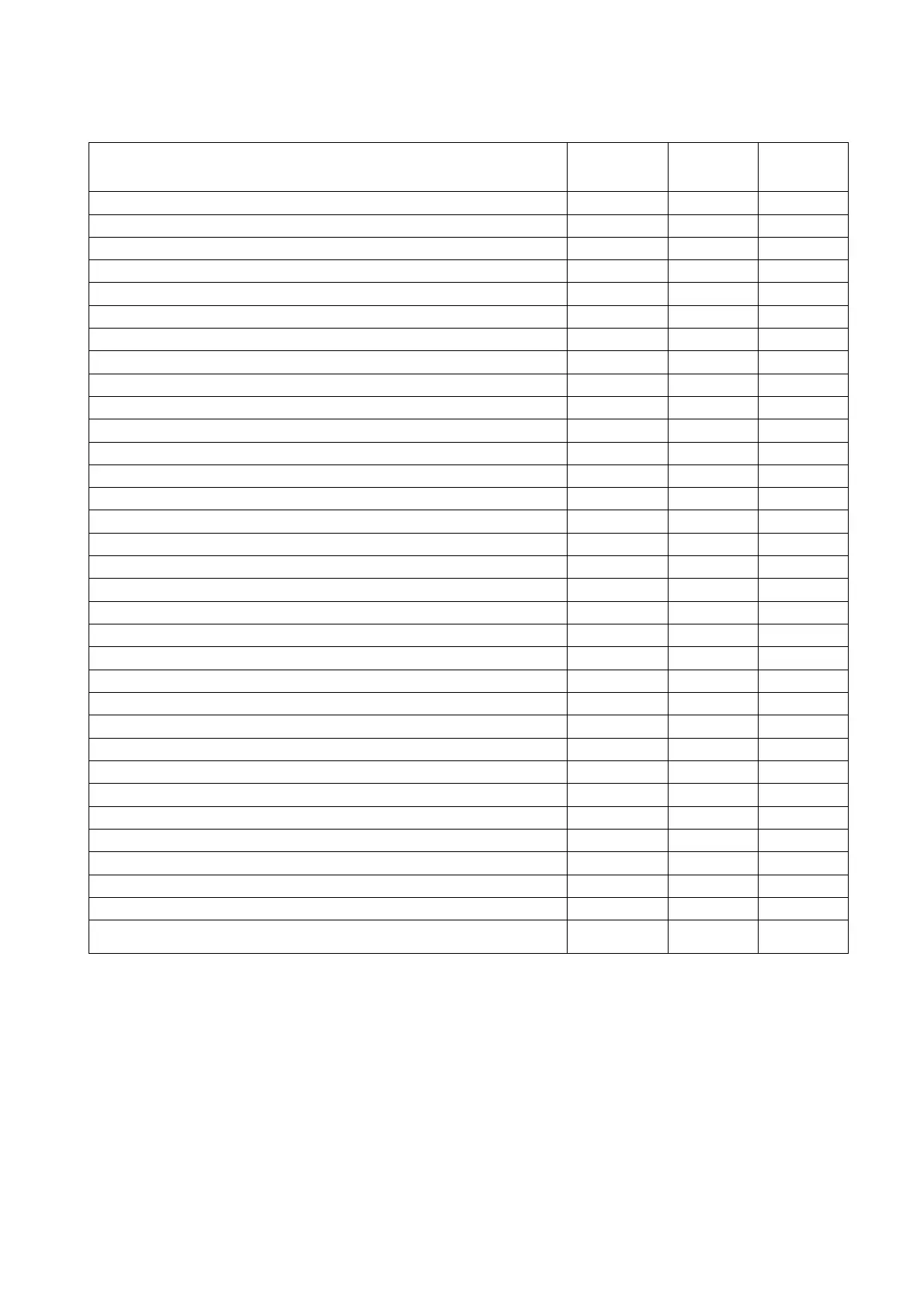

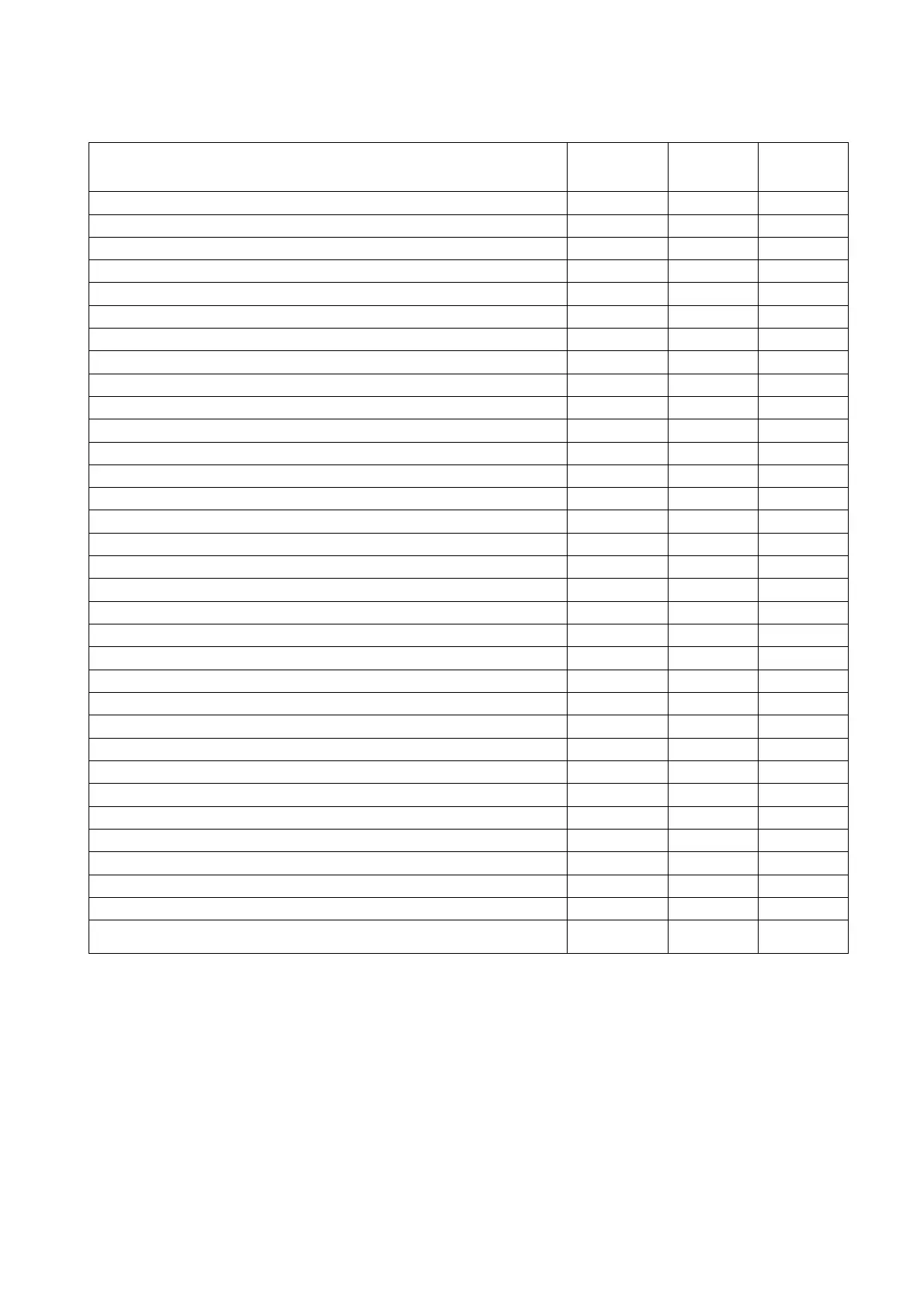

D–EIMAC01603-18_02EN - 23/27

Table 3 –Routine Maintenance Plan for Critical Application and/or Highly Aggressive Environment

List of Activities (Note 8)

Yearly/

Seasonal

(Note 2)

Reading of operating data (Note 3)

Visual inspection of unit for any damage and/or loosening

Verification of thermal insulation integrity

Check of flow switch operation

Verification of control sequence

Verify contactor wear – Replace if necessary

Verify that all electrical terminals are tight – Tighten if necessary

Clean inside the electrical control board

Visual inspection of components for any signs of overheating

Verify operation of compressor and oil heater

Measure compressor motor insulation using the Megger

Clean air intake filters of the electrical panel

Verify operation of all ventilation fans in the electrical panel

Verify operation of inverter cooling valve and heater

Verify status of capacitors in the inverter (signs of damage, leaks, etc)

Check for any refrigerant leakage

Verify refrigerant flow using the liquid sight glass – Sight glass full

Verify filter dryer pressure drop

Verify oil filter pressure drop (Note 5)

Analyse compressor vibrations

Analyse compressor oil acidity (7)

Clean water rinse condenser coils (Note 4)

Quarterly clean condenser coils (E-coated only)

Verify that fans are well tightened

Verify condenser coil fins – Comb if necessary

Check the aspect of the plastic protection of the copper/aluminum

connection

Notes:

1. Monthly activities include all the weekly ones.

2. The annual (or early season) activities include all weekly and monthly activities.

3. Unit operating values should be read on a daily basis thus keeping high observation standards.

4. In environments with a high concentration of air-borne particles, it might be necessary to clean the condenser bank more often.

5. Replace the oil filter when the pressure drop across it reaches 2.0 bar.

6. Check for any dissolved metals.

7. TAN (Total Acid Number) : 0,10 : No action

Between 0.10 and 0.19 : Replace anti-acid filters and re-check after 1000 running hours. Continue to

replace filters until the TAN is lower than 0.10.

0,19 : Replace oil, oil filter and filter dryer. Verify at regular intervals.

8. Units placed or stored in a Highly Aggressive Environment for long time without operation are still subject to those routine

maintenance steps.

Loading...

Loading...