7 English

Insulation of field piping must be carried out up to the con-

nection inside the casing. If the piping is exposed to the

atmosphere, it may cause sweating or burn due to touching

the piping, electric shocks or a fire due to the wiring touch-

ing the piping.

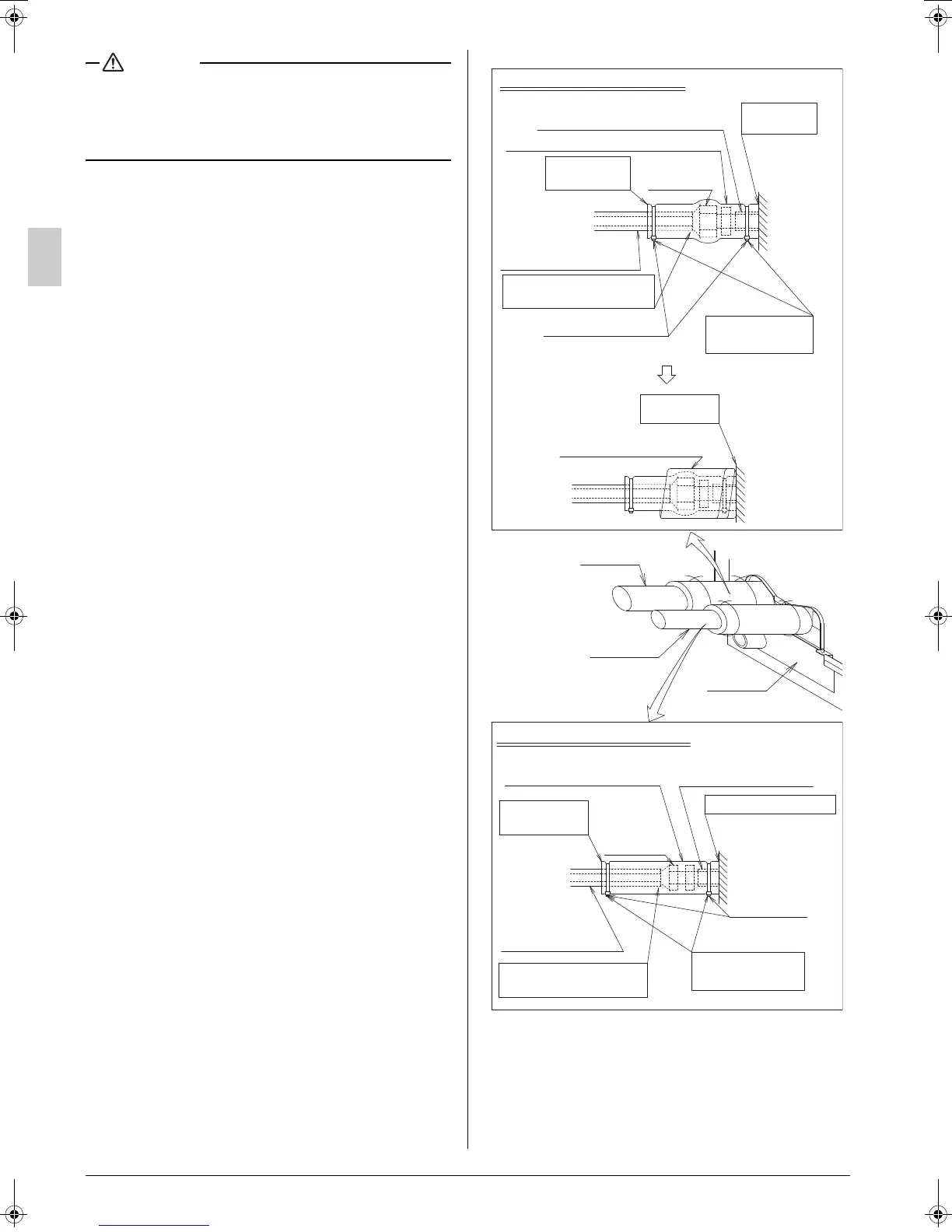

• After leak test, referring to Fig. 15, insulate both the gas and

liquid piping connection with the attached joint insulating

material (6) and (7) to prevent the piping from getting

exposed. Then, tighten the both ends of insulating material

with the clamp (4).

• Wrap the sealing material (Small) (9) around the joint insulat-

ing material (6) (flare nut section), only the gas piping side.

• Make sure to bring the seam of joint insulating material (6)

and (7) to the top.

Joint insulating material (6) (accessory)

Gas side piping insulating method

Piping insulating material (unit side)

Do not leave

clearance

Wrap from the

root of the unit

Sealing material (Small) (9)

(accessory)

Bring the seam

to the top

Flare nut

connection

Piping insulating material

(field supply)

For prevention of sweating,

do not expose the piping

Clamp (4) (accessory)

Tighten the piping

insulating material

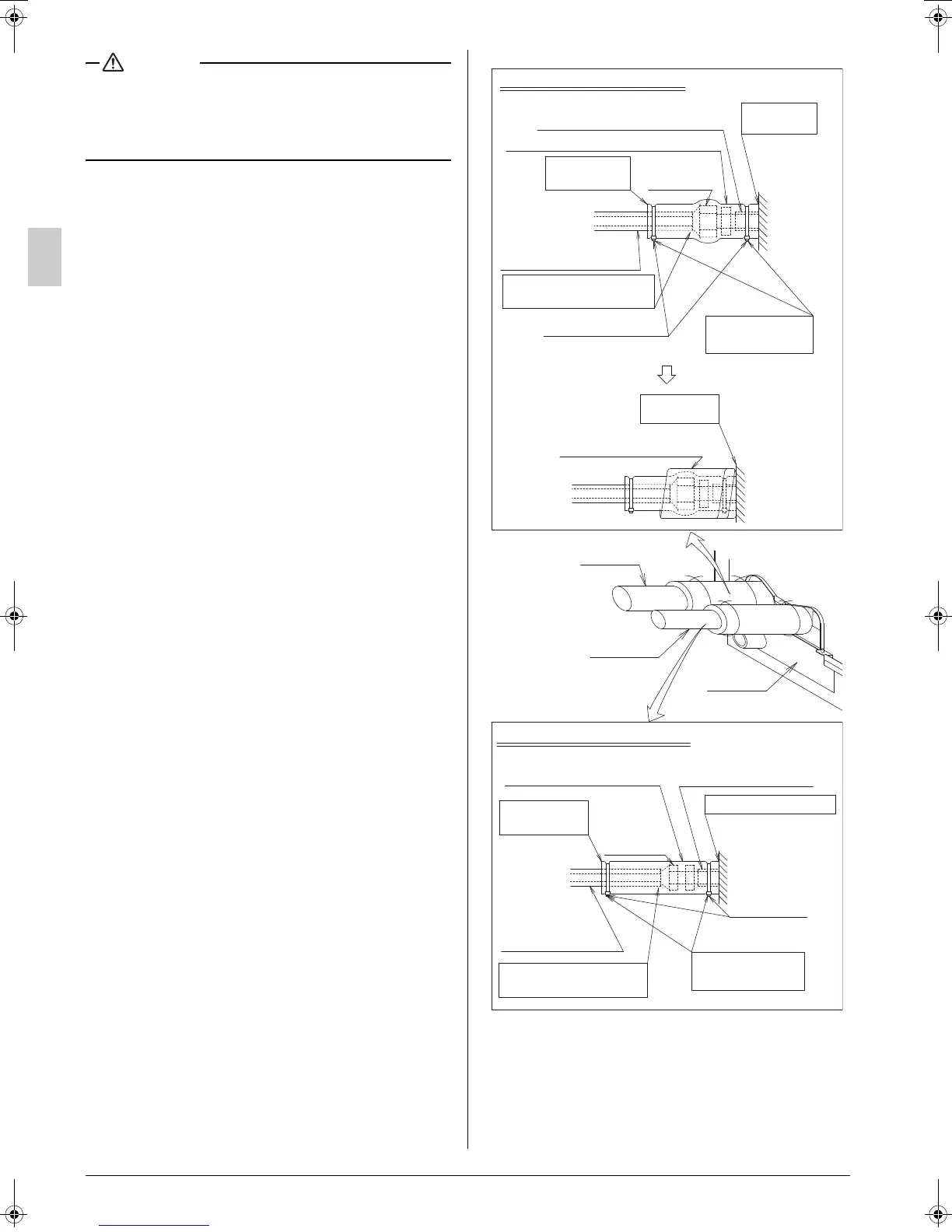

Liquid side piping insulating method

Joint insulating material (7)

(accessory)

Flare nut

connection

Piping insulating

material (field supply)

For prevention of sweating,

do not expose the piping

Fig. 15

Gas piping

Liquid piping

Indoor unit

Bring the seam

to the top

Piping insulating material

(unit side)

Do not leave clearance

Clamp (4)

(accessory)

Tighten the piping

insulating material

01_EN_3P368557-1.fm Page 7 Wednesday, December 10, 2014 10:31 AM

Loading...

Loading...