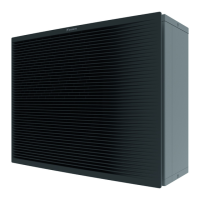

Why does my Daikin GQI-Eco Heat Pump emit an odor?

- LLisa ReynoldsAug 1, 2025

If your Daikin Heat Pump emits an odor, it's likely due to room smells and cigarette odors that have accumulated inside the indoor unit. To resolve this, the inside of the indoor unit must be cleaned.