5.9.1 HOW TO CHECK AND RESTORE THE PRESSURE IN THE

HYDRAULIC TRANSLATION SYSTEM

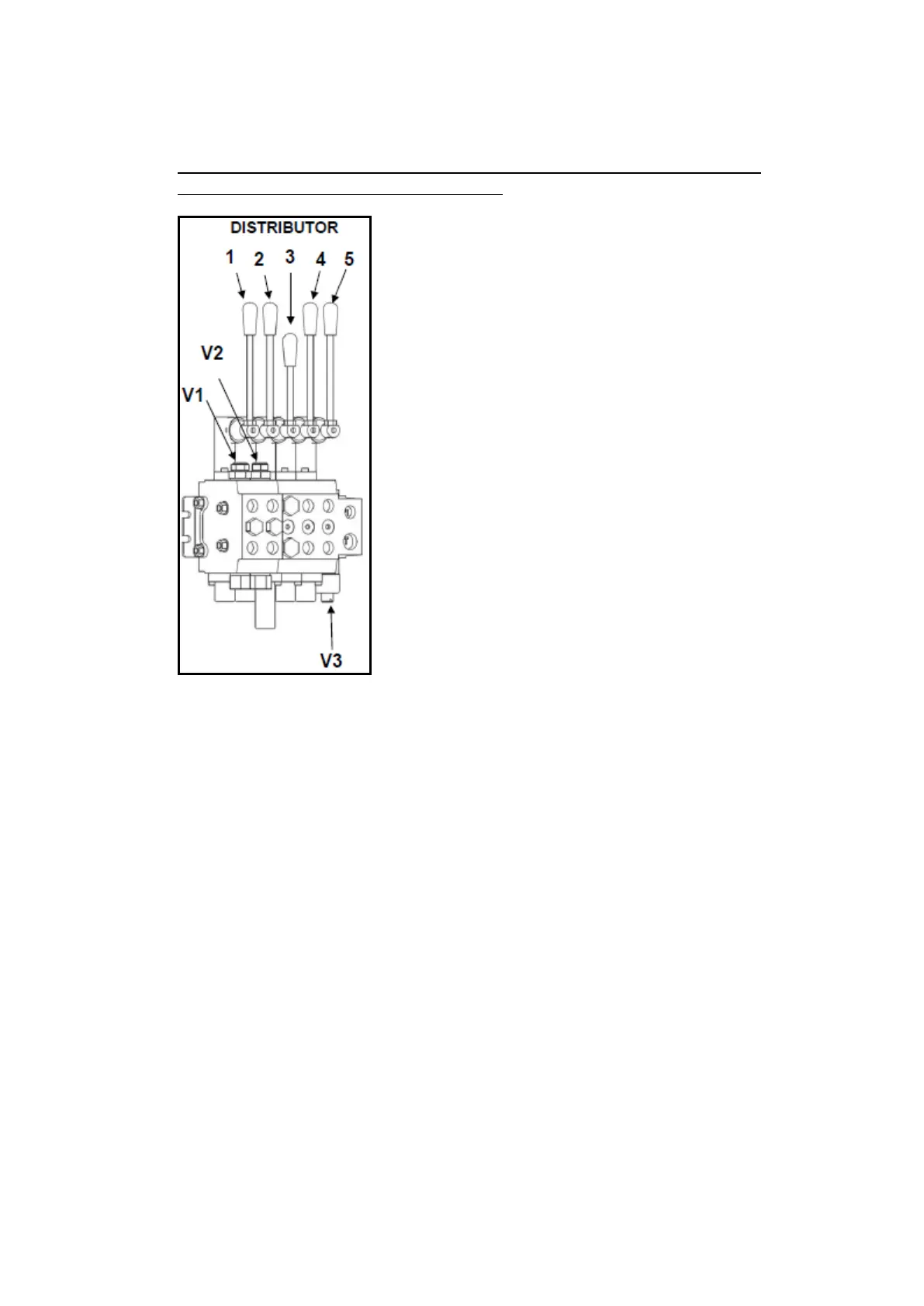

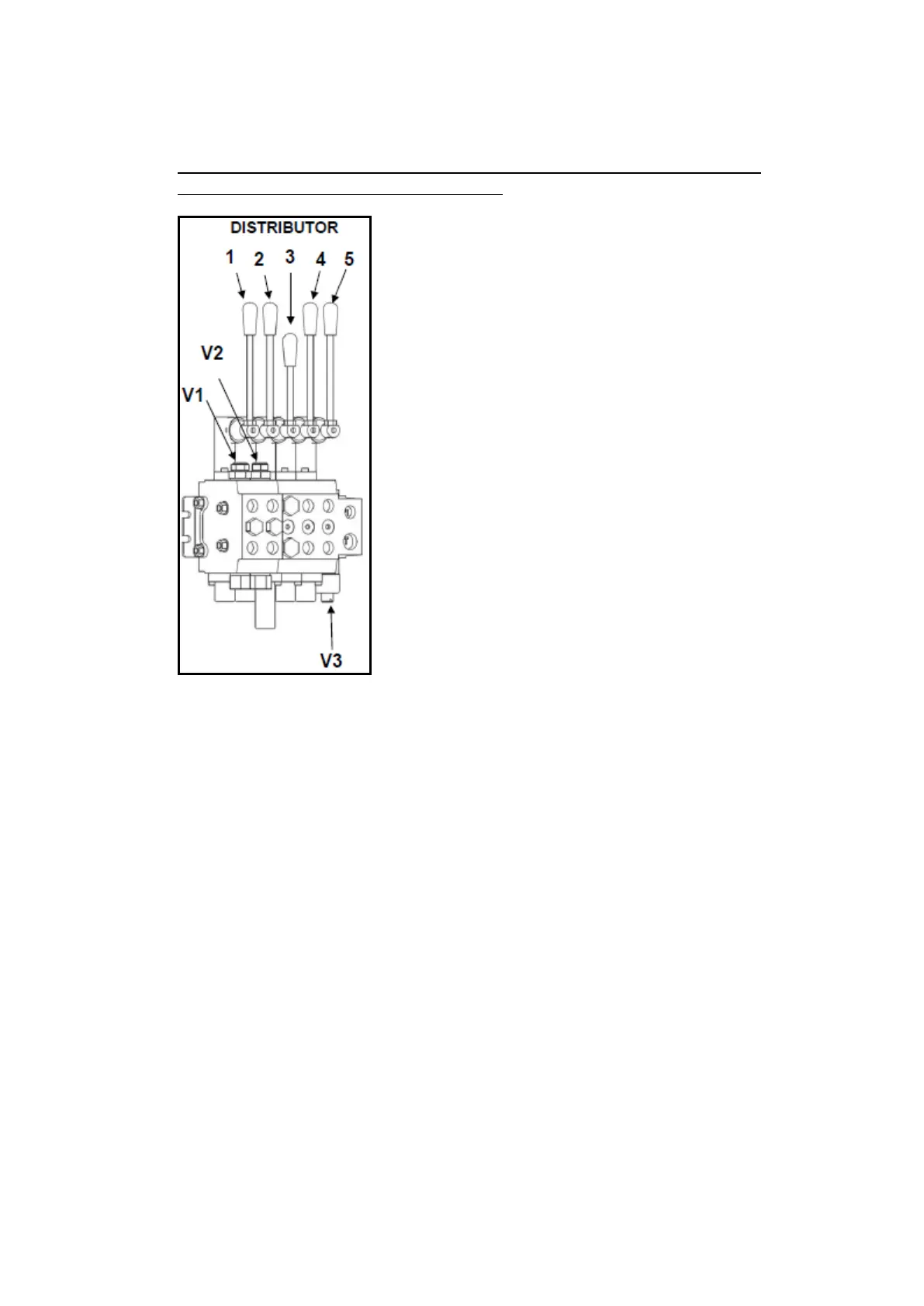

FIGURE 5.8 - DISTRIBUTOR

LEFT TRACK

To check correct pressure, once the manometer has been positioned in

measuring point “P2”, lock the left track by setting a fixed point between the

drive wheel and the machine frame. Rev up the machine to the set number

of revolutions (3600 rpm) and read the pressure indicated on the manometer.

If it does not match the set point, operate the max. pressure valve “V2” set

on the distributor, turning it until the pressure indicated in the table has been

reached.

RIGHT TRACK

To check correct pressure, once the manometer has been positioned in

measuring point “P1”, lock the right track by setting a fixed point between the

drive wheel and the machine frame. Rev up the machine to the set number

of revolutions (3600 rpm) and read the pressure indicated on the manometer.

If it does not match the set point, operate the max. pressure valve “V1” set

on the distributor, turning it until the pressure indicated in the table has been

reached.

Loading...

Loading...