VLT

®

FCM Series

Note that the bus reference can only be preset

via serial communication.

NB!:

It is best to preset terminals that are not

being used to No function [0].

D

ifferentiator gain limit

If very rapid variations occur in an application in either

the reference signal or the feedback signal, the deviation

between the reference/setpoint and the process’s

actual mode will change quickly. The differentiator

can then become too dominant. This is because it

is reacting to the deviation between the reference

and the process’s actual mode, and the quicker the

variance changes the more powerful the differentiator’s

frequency contribution becomes. The differentiator’s

frequency contribution can therefore be limited in such a

way that both a reasonable differentiation time for slow

changes and an appropriate frequency contribution

for quick changes can be preset. This is done using

parameter 443 Process P ID Differentiator gain limit.

L

owpass filter

If there is a lot of noise in the feedback signal, these

can be dampened using an integrated lowpass filter.

A suitable lowpass filter time constant is preset.

If the lowpass filter is preset to 0.1 s, the cut-off

frequency will be 10 RAD/sec, corresponding to (10 / 2

x π) = 1.6 Hz. This will mean that all currents/voltages

that vary by more than 1.6 oscillations per second

will be dampened. In other words, there will only

be regulation on the basis of a feedback signal

that varies by a frequency of less than 1.6 Hz. The

appropriate time constant is selected in parameter

444 Process PID lowpass filter time.

I

nverse regulation

Normal regulation means that the motor speed is

increased when the reference/setpoint is greater than

the feedback signal. If it is necessary to run inverse

regulation, in which the speed is reduced when

the reference/setpoint is greater than the feedback

signal, parameter 437 PID normal/inverse control

must be programmed at Inverted .

A

nti Windup

In the factory the process regulator is preset with

an active anti windup function. This function means

that when either a frequency limit, a current limit or

a voltage limit is reached, the integrator is initialised

at a frequency corresponding to the present output

frequency. This is a means of avoiding the integration

of a variance between the reference and the process’s

actual mode that cannot be deregulated by means of

a change of speed. This function can be deselected

in parameter 438 Process PID anti windup.

S

tarting conditions

In some applications the optimal setting of the

process regulator will mean that a relatively long

period of time will pass before the required process

condition is achieved. In these applications it can

be a good idea to define an output frequency to

which the frequency converter must run the motor

before the process regulator is activated. This is

done by programming a start frequency in parameter

439 Process PID start frequency.

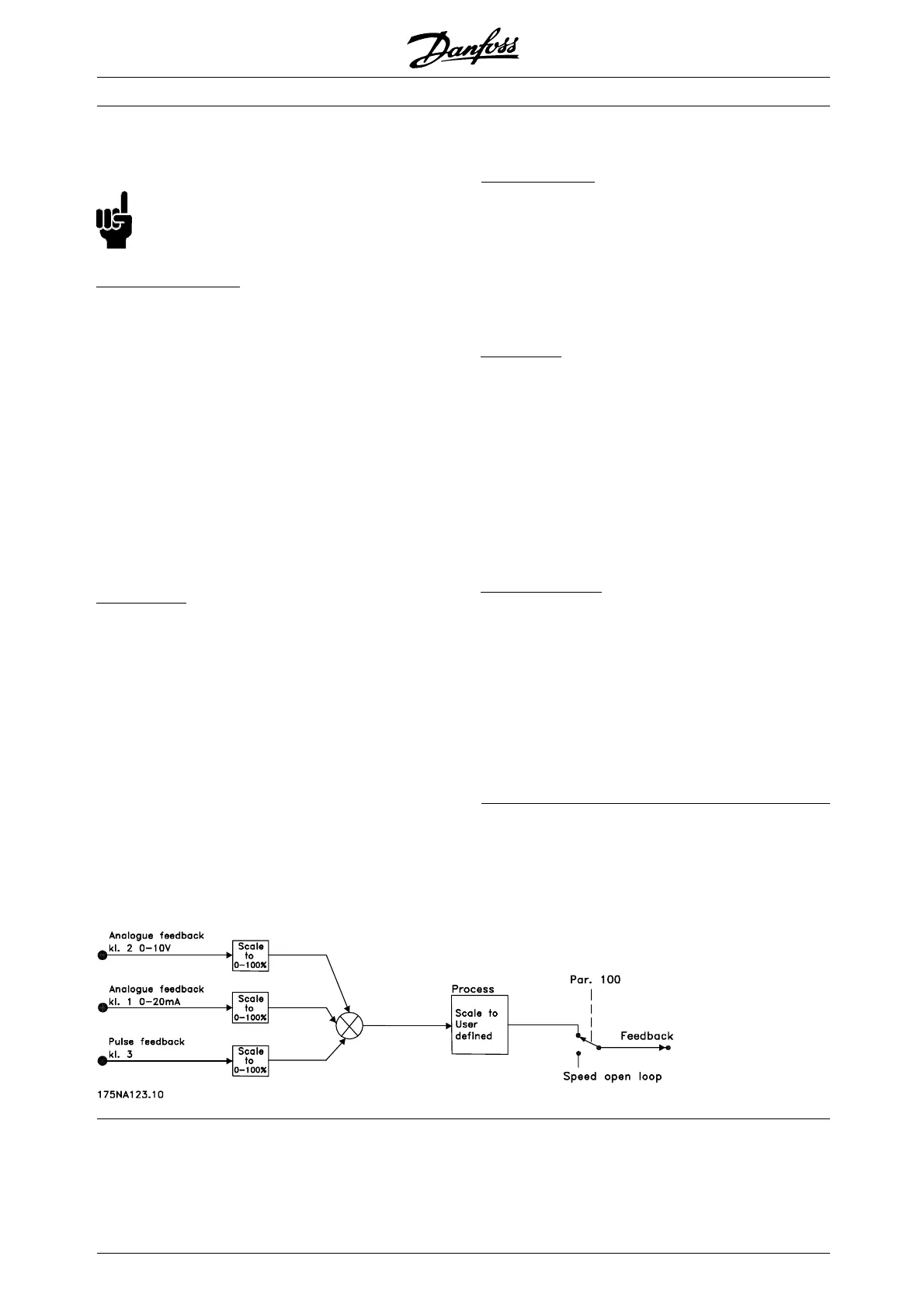

■ Handling of feedback

Feedback handling is depicted in this flowchart.

The flowchart shows which parameters can affect the

handling of feedback and how. A choice can be made

between voltage, current and pulse feedback signals.

✭ = factory setting. () = display text [] = value for use in communication via serial communication port

MG.03.H3.02 - VLT is a registered Danfoss trademark

64

Loading...

Loading...