March 2010

March 6, 2009

Fig. 3-5

Never expose the underside of the DAVCO® Brush Cutter to the operator’s cab (Fig.

3-5) or to personnel within sight of the machine. Flying debris can cause equipment damage, serious injury

or death. Never exit cab while loader arms are raised.

4. Knife change

Fig. 4-1

Remove the disc inspection cover (1) in Fig. 4-1 to gain access to the top of the disc.

Rotate the disc by hand until the first set of knife bolts are visible in the hole.

Fig. 4-2

To remove the knives, set the DAVCO® Brush Cutter on the stand or blocks, undo

the nuts (as illustrated on Fig 4-2), drop the bolts, and then remove the knives and the pucks horizontally.

To install the knives, reverse the procedure, and torque the bolts to 250 ft/lb for Course thread or 300 ft

lbs for fine thread bolts. Note- Remember to re-torque the bolts after the first 8 hours of operation

following a knife replacement

5. Identification

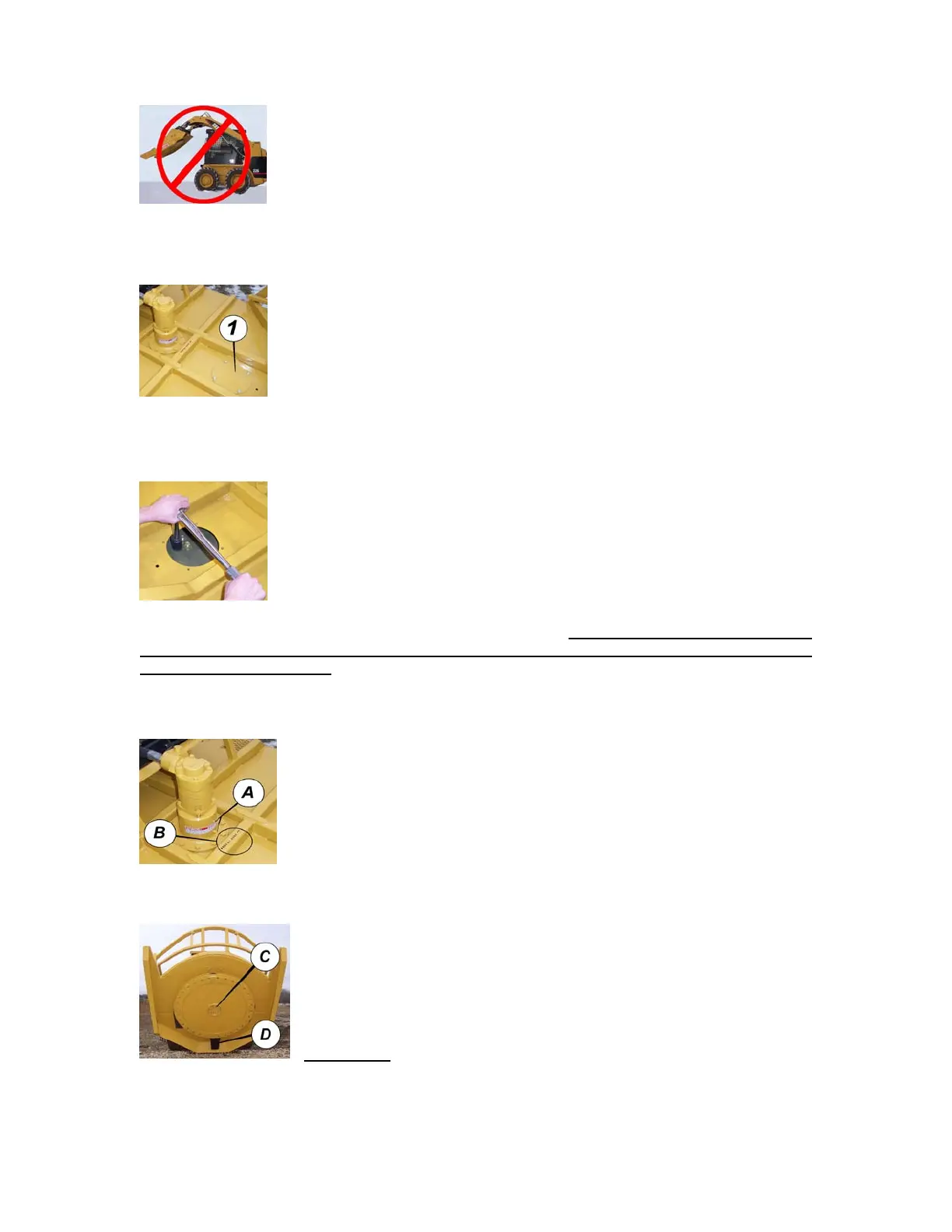

Fig 5-1

Fig. 5-1 shows the identification of the DAVCO® Brush Cutter that includes the

serial numbers and the model (B). Please refer to these numbers when calling for technical support, or

replacement parts.

Fig 6-1

Spindle bolts (Item A in Figure 6-1) must be torqued to 300 ft/lb. Inspect

periodically.

Loading...

Loading...