14

Note: All wire gauge sizes and breaker ratings noted are the recommended size. Larger gauge wiring

and higher breaker rating may be used. There may be variances on specic systems supplied to OEM

customers due to the exact makeup of the system.

Additional information on Power Supply connections

Additional Notes on Wiring

The below is just general information to be used as a guide.

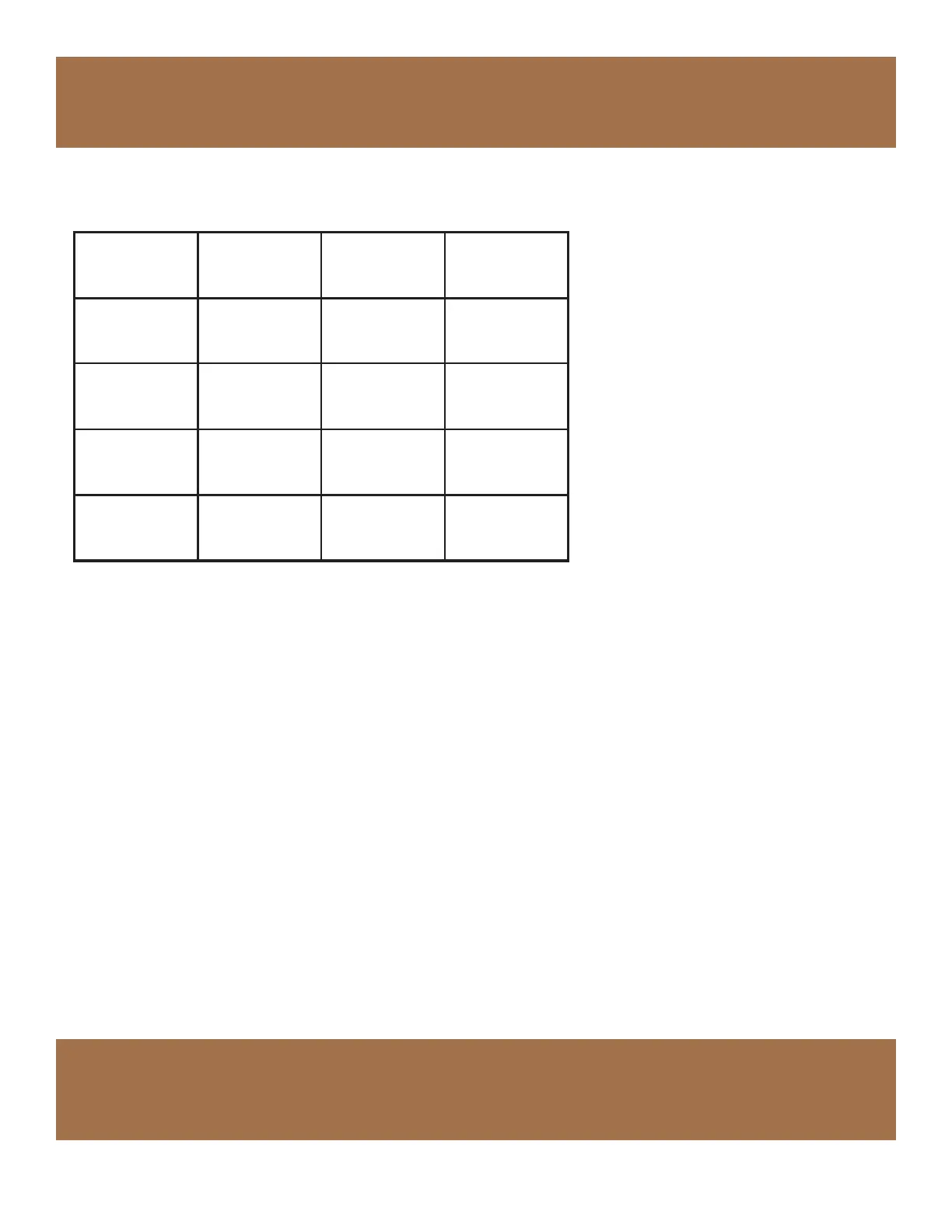

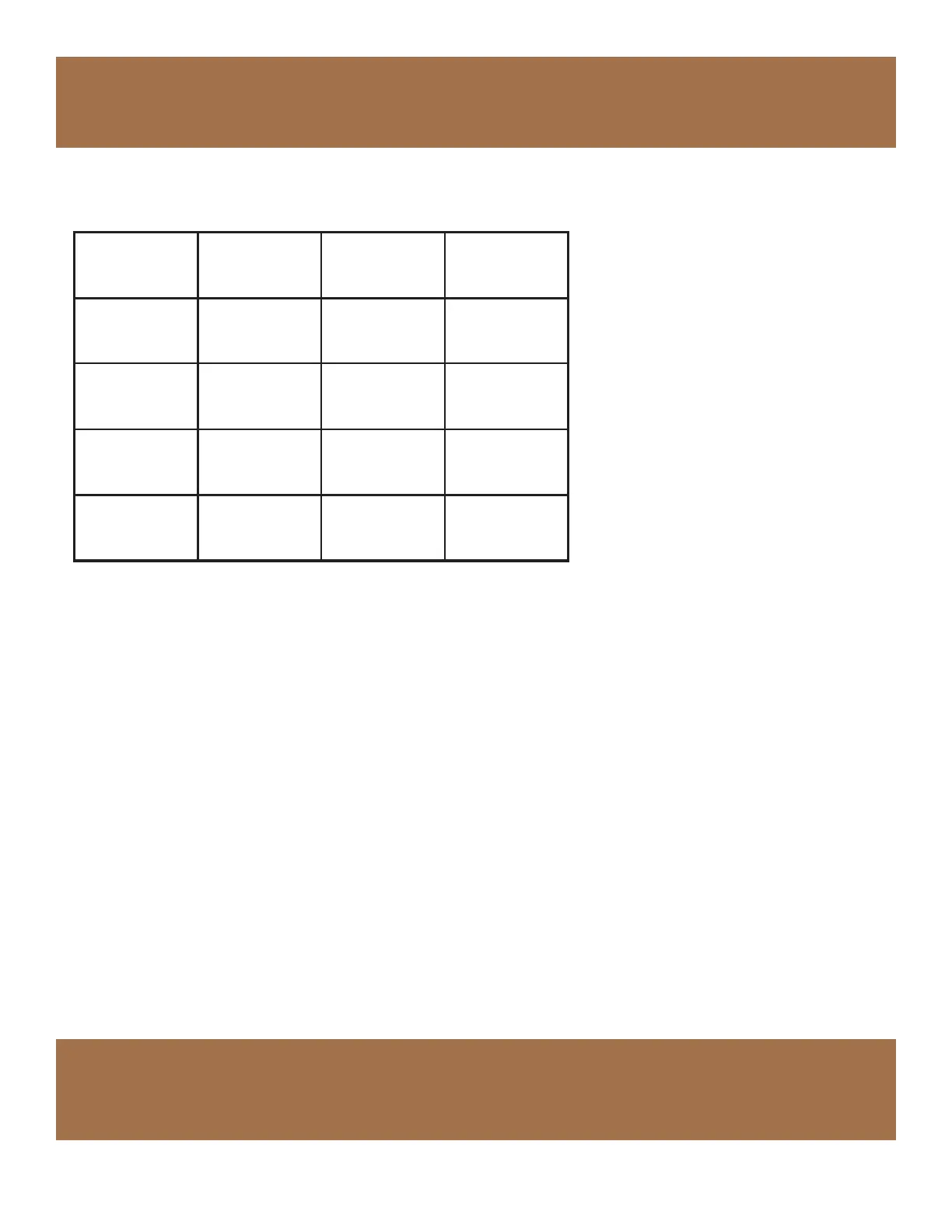

Battery Size

Considerations

Generally, the greater the

size of the battery or bank the

better. A group 24 RV deep

cycle marine battery should

be considered the minimum.

Multiple batteries connected

in parallel is common. The

battery or bank should have

some sort of charging system

in place to keep the battery

or bank at peek charge for

proper operation.

Pump #’s

Recommended Min

Wire Gauge Size

Circuit Breaker

Normal Pump

Amperage

3195KS, 3195, 3043 4 or 6 Gauge 100 40 - 100

2542KS, 2532, 2542 2 or 4 Gauge 150 60 - 140

3218 2 or 4 Gauge 150 60 - 140

1551 2 or 4 Gauge 150 60 - 150

Battery Type and Size

A minimum group 24 RV/marine type battery is recommended. Battery rating should be a minimum

100 RC (Reserve capacity) with a 500 CCA (Cold Cranking Amperage). The higher these numbers

the better. Common types are ooded lead acid, Gel and AGM (Absorbed Glass Mat).

Note: Some lithium batteries are not suited for this application. As they cannot provide the high

running amperage and surges. Check with the battery supplier/manufacture for info on this.

Circuit Breakers

The breaker should be of the manual reset type that is typical of the RV/Marine industries usage.

This should be of the “slow blow or trip type” to avoid nuisance tripping due to current surges common

to the hydraulic pump motor start up. These surges may be many times the normal pump amperage

generally lasting only milliseconds.

Note: if a fuse is used in lieu of a breaker, a “slow blow” type of higher amperage rating is

recommended to prevent nuisance “blowing” of the fuse.

The purpose of the breaker is to provide protection against shorting to ground of the positive feed to

the pump assembly. It is not needed for system overload protection which is provided by the hydraulic

systems relief circuit.

There may be additional wiring at the pump or near the control panel for specic OEM requirements.

Check with Equalizer Systems on the usage of these if present.

Loading...

Loading...