Publication 85B

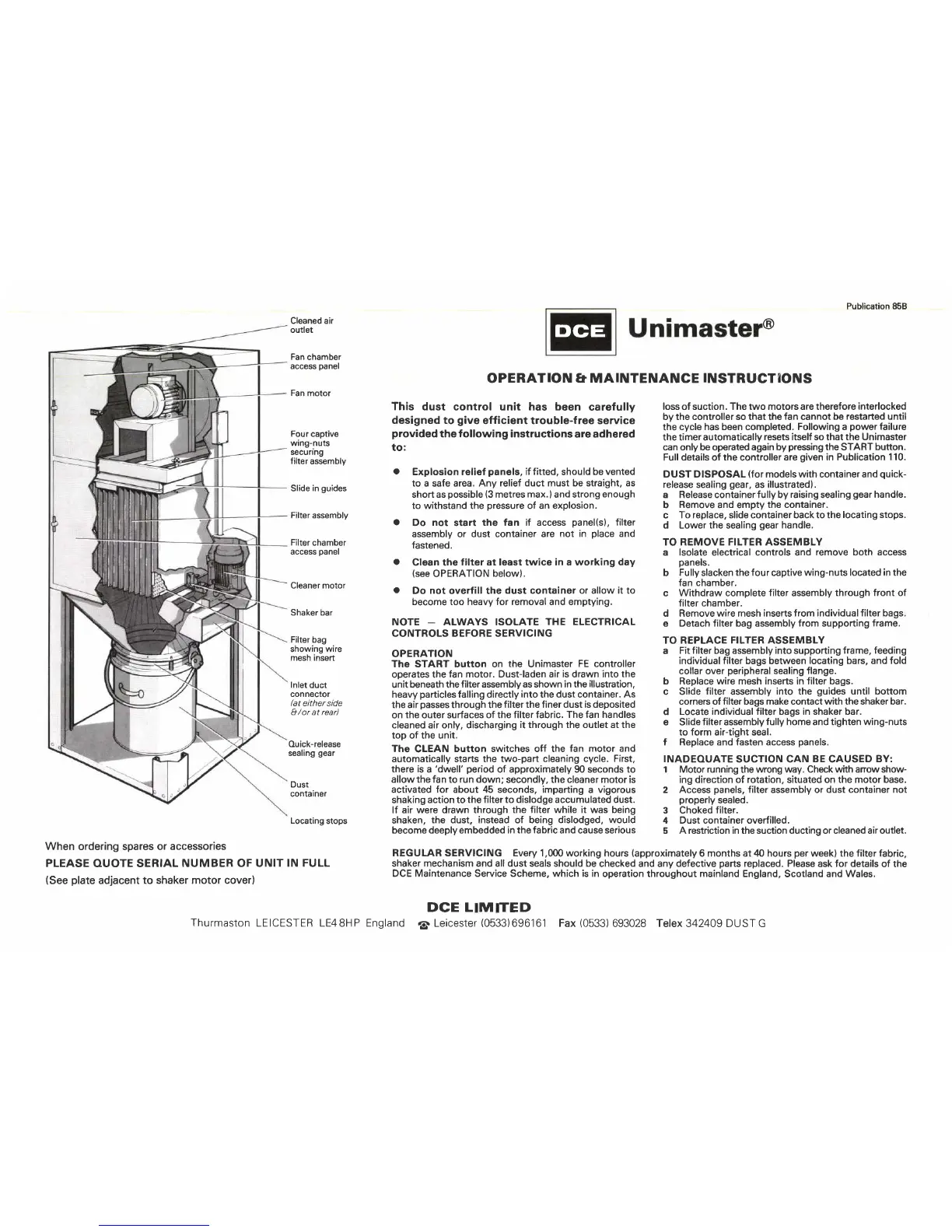

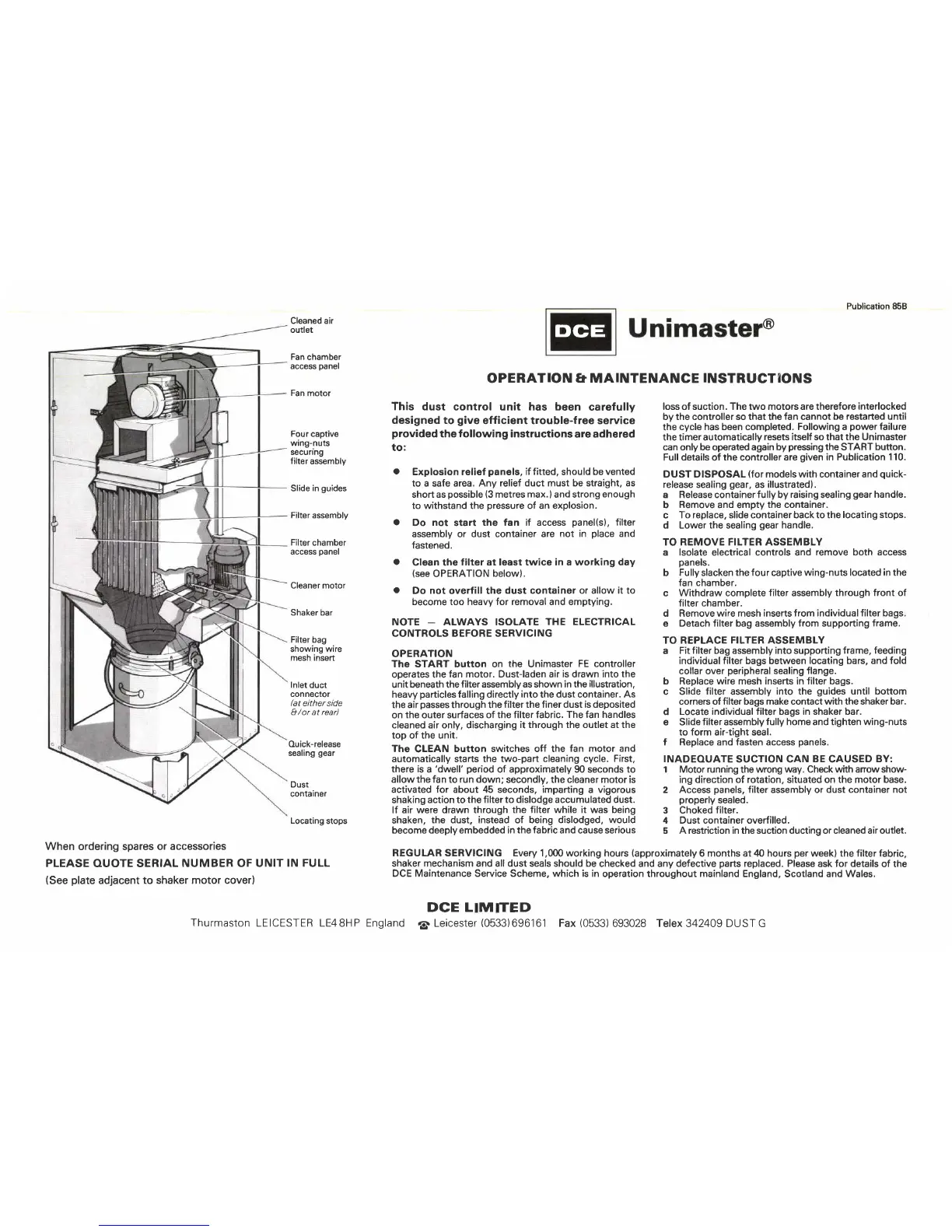

Cleaned air

outlet

Fan

chamber

access

panel

Fan

motor

Four captive

wing-nuts

secunng

filter

assembly

Slide

in

guides

Filter assembly

Filter chamber

access

panel

Cleaner motor

Shaker bar

Filter bag

showing wire

mesh insert

lnlet

duct

connector

bt either side

I /or at rear)

Ouick-release

sealing

gear

Dust

container

Locating

stops

When ordering spares or

accessories

PLEASE

OUOTE SERIAL

NUMBER OF UNIT

IN FULL

(See

plate

adjacent

to shaker motor cover)

DCE

This

dust control unit has been

carefully

designed to

give

efficient trouble-free service

provided

the following instructions

are adhered

to:

a

Explosion relief

panels,

if fitted,

should

be vented

to a safe area, Any

relief duct must be straight, as

short as

possible

(3

metres

max.

)

and strong

enough

to withstand the

pressure

of an

explosion.

a

Do

not

start

the fan if access

panel(s),

filter

assembly or dust container are

not in

place

and

fastened.

a

Clean the

filter at least twice in a working day

(see

OPERATION

below).

a

Do not overfill the

dust container or allow it to

become too heavy for removal and emptying.

NOTE

_

ALWAYS ISOLATE

THE ELECTRICAL

CONTROLS BEFORE SERVICING

OPERATION

The START button on

the

Unimaster

FE controller

operates the

fan motor. Dust-laden air

is

drawn into

the

unit beneath the

filter assembly as shown in the

illustration,

heavy

particles

falling directly

into

the dust container.

As

the air

passes

through the

filter the finer dust is deposited

on

the

outer surfaces

of the filter fabric.

The fan handles

cleaned air only, discharging

it through the outlet at the

top of the unit.

The

CLEAN

button switches off the

fan motor and

automatically starts the two-part

cleaning cycle. First,

there is

a

'dwell' period

of approximately 90 seconds to

allow the fan

to

run down;

secondly, the cleaner motor is

activated for about 45 seconds, imparting

a

vigorous

shaking action to

the filter to dislodge accumulated dust.

lf air were drawn through

the filter while it was being

shaken,

the dust, instead of being dislodged, would

become deeply embedded in the

fabric

and cause serious

@

OPERAT ON

ET

MA NTENANCE NSTRUCT

ONS

loss of suction. The two motors are therefore

interlocked

by the controller so that the

fan

cannot

be restarted until

the

cycle has been completed. Following a

power

failure

the timer automatically

resets itself so that the Unimaster

can only be operated again by

pressing

the START

button.

Full

details

of

the

controller

are

given

in Publication

110.

DUST DISPOSAL

(for

models with container and

quick-

release sealing

gear,

as illustrated).

a Release container f ully by

raising

sealing

gear

handle.

b

Remove

and empty

the container.

c

To replace, slide container back to the

locating stops.

d Lower the sealing

gear

handle.

TO REMOVE FILTER ASSEMBLY

a lsolate electrical controls and

remove both access

panels.

b

Fully

slacken

the four

captive

wing-nuts located in the

fan chamber.

c Withdraw complete

filter

assembly

through front of

filter chamber.

d Remove wire mesh

inserts from individual filter bags.

e Detach filter bag assembly from supporting

frame.

TO REPLACE

FILTER

ASSEMBLY

a

Fit filter bag assembly into supporting frame, feeding

individual

filter

bags between

locating bars, and fold

collar over

peripheral

sealing flange.

b Replace wire mesh inserts in filter bags.

c Slide

filter

assembly

into the

guides

until bottom

corners of filter bags make contact with the shaker bar.

d

Locate individual filter bags in shaker bar.

e Slide

filter

assembly

fully home and tighten wing-nuts

to form air-tight seal.

f Replace and fasten access

panels.

INADEOUATE

SUCTION CAN

BE

CAUSED

BY:

1

Motor

running

the wrong

way. Check with anow show-

ing direction of rotation, situated on the motor base.

2 Access

panels,

filter

assembly or

dust container not

properly

sealed.

3 Choked

filter.

4 Dust container overfilled.

5 A restriction in the suction ducting or cleaned air outlet.

REGULAR SERVICING Every 1,000

working hours

(approximately

6 months at

zl0

hours

per

week) the filter fabric,

shaker mechanism and all dust seals should be

checked and any defective

parts

replaced. Please ask for details

of the

DCE Maintenance Service Scheme, which is in

operation throughout mainland England,

Scotland

and Wales.

DCE L M TED

Thurmaston

LEICESTER LE48HP England

O,

Leicester

(0533)696161

Fax

(0533)

693028 Telex 342409 DUSTG

Loading...

Loading...