lrla

@

T LL

TY

T9, 12, 23 30

FUNCTION

This controller

ensures the efficient

cleaning

of

the

filter

mattress

on initiation of a cleaning

rycle

after

each

dutycycle of

the

Unimaster dust control

unit.

To

protect

the Unimaster filter fabric, the

controller

is interlocked so.that the fan motor

cannot

be

restarted during the operation of the cleaner

motor.

SPECIFICATION

The equipment is housed

in

a

rigid

H/C box

designed

to

lP65

protection,

with

cable entries

at top

and

bottom.

Functioning

as a dual direct-on-line

starter,

it

comprises

(1)

a double-wound transformer

with

a

selection of input tappings for the

incoming supply,

gMng

an

output of 24Y AC;

(2)two

contactors

labelled

K1 and K2

(electrically

interlocked to

prevent

simultaneous operation) to control the

fan and cleaner

motors;

(3)

a thermal overload

relay with

single

phase protection

for the fan motor

(no

protection

being

supplied for

the cleaner

motor except

where

required

by national

regulations,

as

in France);

(4)

a

pre-set

electronic

timer

module controlling

the

'fan

rundown' and'cleaning'

periods.

These components

are all

mounted

on a baseplate

within the box.

Timer

ambient temperature

range is

-5"C

to

+40'C.

For temperatures

outside these

limits

please

refer

to DCE.

!NSTALI.ATION

Mount

the controller

independently of the Unimaster

dust control unit on a vertical surface

free of

vibration.

Bring

the

incoming

mains

via

a

switch-fuse

unit

(preferably

'on-load'

typelto the terminal

block,

{see

Table

1

for the fuse rating). Seal all

joints

at conduit

entry

holes

to

prevent

dust entering

the box.

Publication

16244

(GB)

OVERLOAD

SETIING

IMPORTANT

Before start-up,

the overload

relay

calibration

lever must be set

at the value

given

by

motor

full load current

in Table

2.

OPERANNG

RANGE

The controlldr

is.suitable

for use on a

range of

3-phase,

50

-

60

Hz operating

voltages,

with fan

motors

rated up to and

including some

at 11 kW.

A

stardelta

(Y/A)

controller,

type

ECT SD, is available

for other

11 kW fans. S6e

Table

2.

A variance

of t10o/o is

allowable on transformer

input tappings.

OPERATION

1. START

(average

operating

period

for fan, 4 hours)

Press

'START'

button:

o Fan

contactor K1

is

energized;

timer

module

sets

and

fan motor runs.

2. CLEAN

Press'CLEAN' button:

o Fan

contactor

K1 is de+nergized

and the

timer

energized.

O After

approximately 90

seconds

cleaner

motor

contactor

K2 is energized;

cleaner motor

now

runs

for approximately

45 seconds.

o Cleaner

motor

contactor

is

decnergized

and

the

timer

resumes inactive state.

Before

a cleaning

cycle can be

initiated

by

pressing

the

'CLEAN'

button,

thefan

contactor

K1 must

have

remained

energized

for at least

30 seconds.

A

'fail-safe'feature ensures that

if the

power

supply

fails

while the timer

is

performing

a cycle,

then

re-

applying

the

power

will not cause

the cycle

to be

completed.

I nstead, the controller

will

automatically

re-set

ready for the fan to

be restarted.

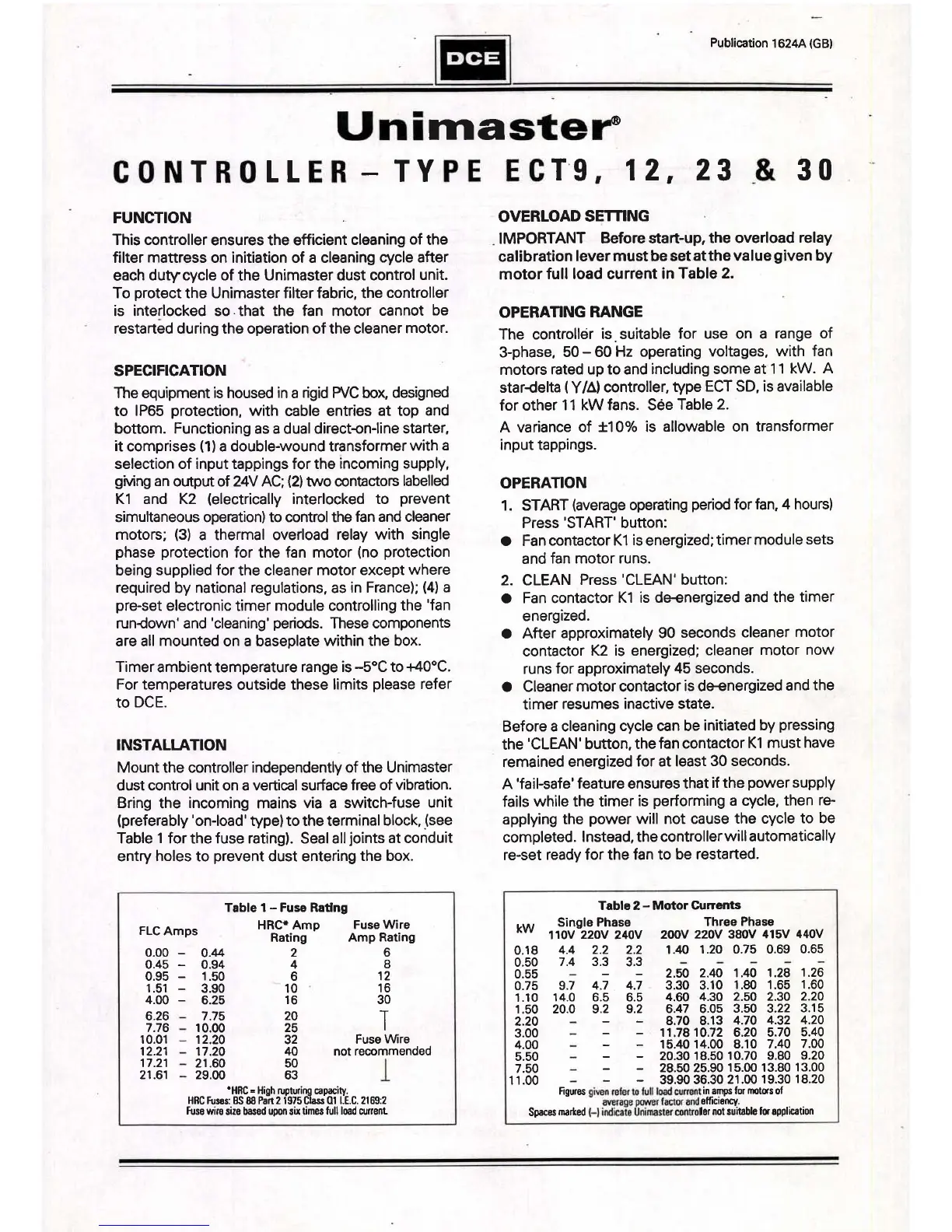

KW

0.18

0.50

0.55

0.75

1.10

1,50

2.20

3.00

4.00

5.50

7.50

11.00

1.28

1.65

2.30

3.22

4.32

5.70

7.40

9.80

13.80

19.30

'1.26

1.60

2.20

3.15

4.20

5.40

7.00

9.20

13.00

18.20

Single Phase

110v

220v

240v

4.4

7.4

9.7

14.0

20.0

Table2-MotorCurtents

Three

Phase

200v

220v 380v

415v 440v

1.40 1.20 0.75 0.69

0.65

2.2 2.2

3.3

3.3

4.t 4.7

6.5 6.5

,r_

r:

2.50

2.40 1.40

3.30 3.10

1.80

4.60 4.30

2.50

6.47 6.05

3.50

8.70 8.13

4.70

11.7810.72 6.20

15.4014.00

8.10

20.3018.5010.70

28.50 25.90

15.00

39.90 36.30

21.00

Figwes

in-amps lor

motds

o,

otlrcrSrlcY-

Spaces

marted

le, not suitablo

to.

application

FLC

Amps

0.00

-

0.45

-

0.95

-

1.51

-

4.00

-

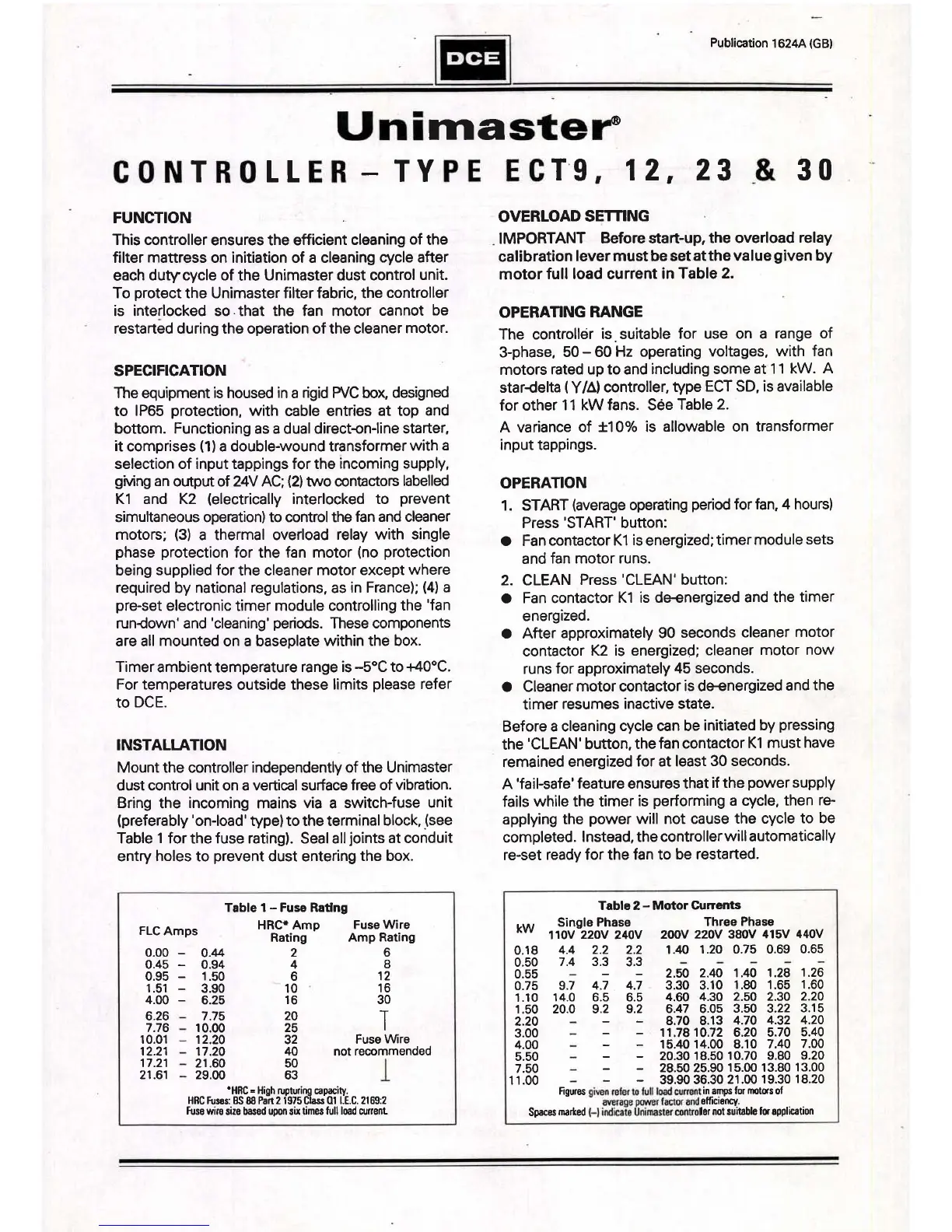

Tablel-FuseRadng

HRC'Amp

Rating

Fuse Wire

Amp Rating

6

8

'12

16

30

o.M

0.94

1.50

3.90

6.25

2

4

6

10

16

20

25

32

40

50

63

6.26

7.76

10.01

12.21

17.2'.1

21.61

7.75

10.00

12.20

17.20

21.60

29.00

T

Fuse

\Nire

not

recommended

'HRC.

High rupturing capacity.

HRC Fusas: BS

88

Pan 2 1975

Class

0l l.E.C. 21 69:2

Fuse

wiro

sire basod

upon

sir

times

full load

curent

Loading...

Loading...