Fuel,

Emission and Exhaust System

D:04:01

EMISSION CONTROL SYSTEM

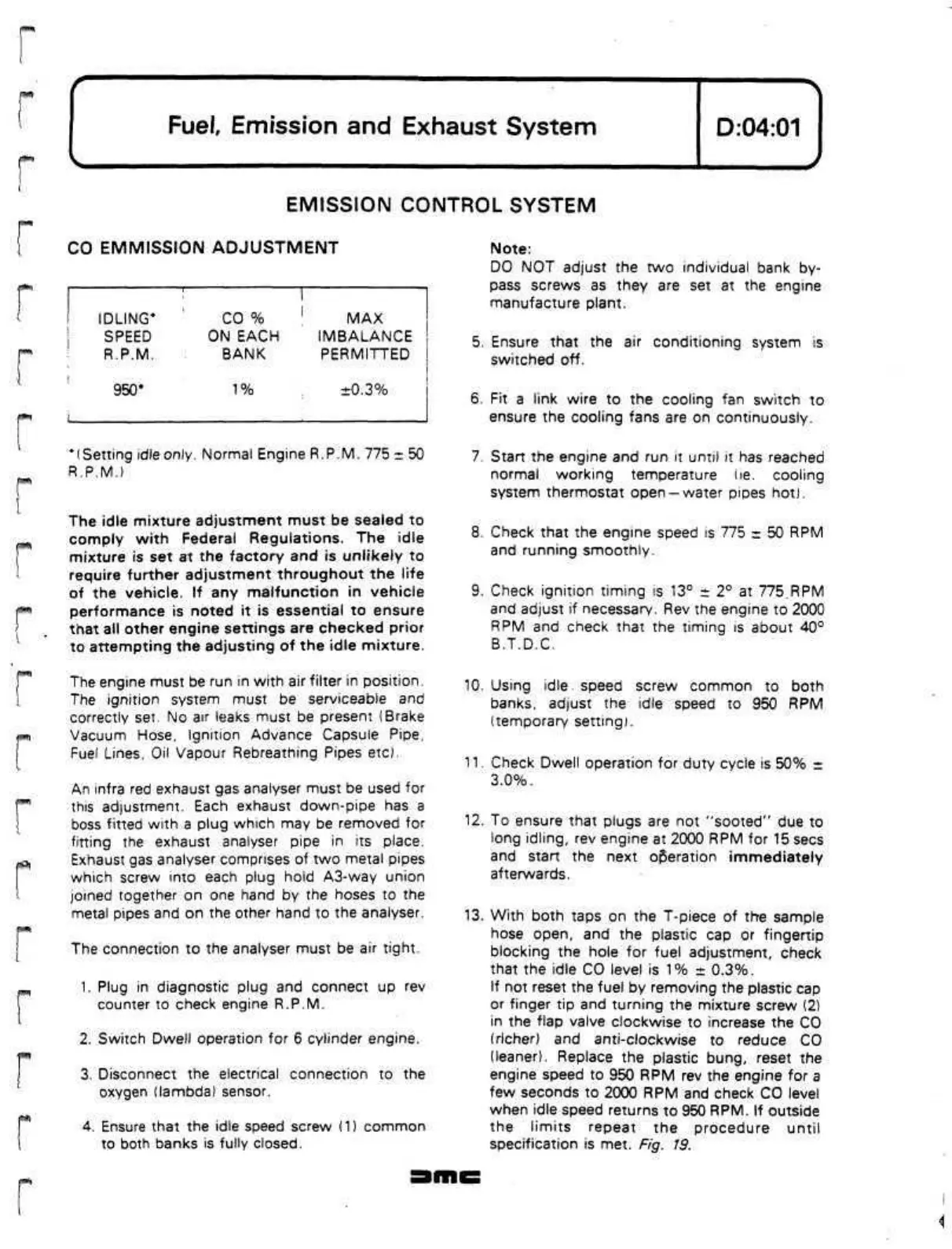

CO EMMISSION ADJUSTMENT

IDLING*

SPEED

R.P.M.

950*

T

CO

%

ON EACH

BANK

1%

1

1

MAX

IMBALANCE

PERMITTED

±0.3%

i

'(Setting

idle only. Normal Engine R.P.M. 775 r 50

R.P.M.)

The idle mixture adjustment must be sealed to

comply with Federal Regulations. The idle

mixture is set at the factory and is unlikely to

require further adjustment throughout the life

of the vehicle. If any malfunction in vehicle

performance is noted it is essential to ensure

that all other engine settings are checked prior

to attempting the adjusting of the idle mixture.

The engine must be run in with air filter in position.

The ignition system must be serviceable and

correctly set. No

air

leaks must be present (Brake

Vacuum Hose, Ignition Advance Capsule Pipe,

Fuel Lines, Oil Vapour Rebreathing Pipes etc).

An

infra

red exhaust gas analyser must be used for

this adjustment. Each exhaust down-pipe has a

boss fitted

with

a plug which may be removed for

fitting the exhaust analyser pipe in its place.

Exhaust gas analyser comprises of two metal pipes

which screw

into

each plug hold A3-way union

joined together on one hand by the hoses to the

metal pipes and on the other hand to the analyser.

The connection to the analyser must be air tight.

1.

Plug in diagnostic plug and connect up rev

counter to check engine R.P.M.

2.

Switch Dwell operation for 6 cylinder engine.

3. Disconnect the electrical connection to the

oxygen (lambda) sensor.

4.

Ensure that the idle speed screw (1) common

to both banks is fully closed.

Note:

DO NOT adjust the two individual bank by-

pass screws as they are set at the engine

manufacture plant.

5. Ensure that the air conditioning system is

switched off.

6. Fit a link wire to the cooling fan switch to

ensure the cooling fans are on continuously.

7.

Stan

the engine and run it until it has reached

normal working temperature

lie.

cooling

system thermostat open

—water

pipes hot).

8. Check that the engine speed is 775

=

50 RPM

and running smoothly.

9. Check ignition timing

is

13° ± 2° at

775.RPM

and adjust if necessary. Rev the engine to 2000

RPM and check that the timing

is

about 40°

B.T.D.C.

10.

Using

idle

speed screw common to both

banks, adjust the idle speed to 950 RPM

(temporary setting).

11.

Check Dwell operation for duty cycle is 50%

*

3.0%.

12.

To ensure that plugs are not "sooted" due to

long idling, rev engine at 2000 RPM for 15

sees

and start the next

operation

immediately

afterwards.

13.

With both taps on the T-piece of the sample

hose open, and the plastic cap or fingertip

blocking the hole for fuel adjustment, check

that the idle CO level is 1% ± 0.3%.

If not reset the fuel by removing the plastic cap

or finger tip and turning the mixture screw (2)

in the flap valve clockwise to increase the CO

(richer) and anti-clockwise to reduce CO

(leaner). Replace the plastic bung, reset the

engine speed to 950 RPM rev the engine for a

few seconds to 2000 RPM and check CO level

when idle speed returns to 950 RPM. If outside

the limits repeat the procedure until

specification is met. Fig. 19.

&Wy

Loading...

Loading...