W&\

rrw\

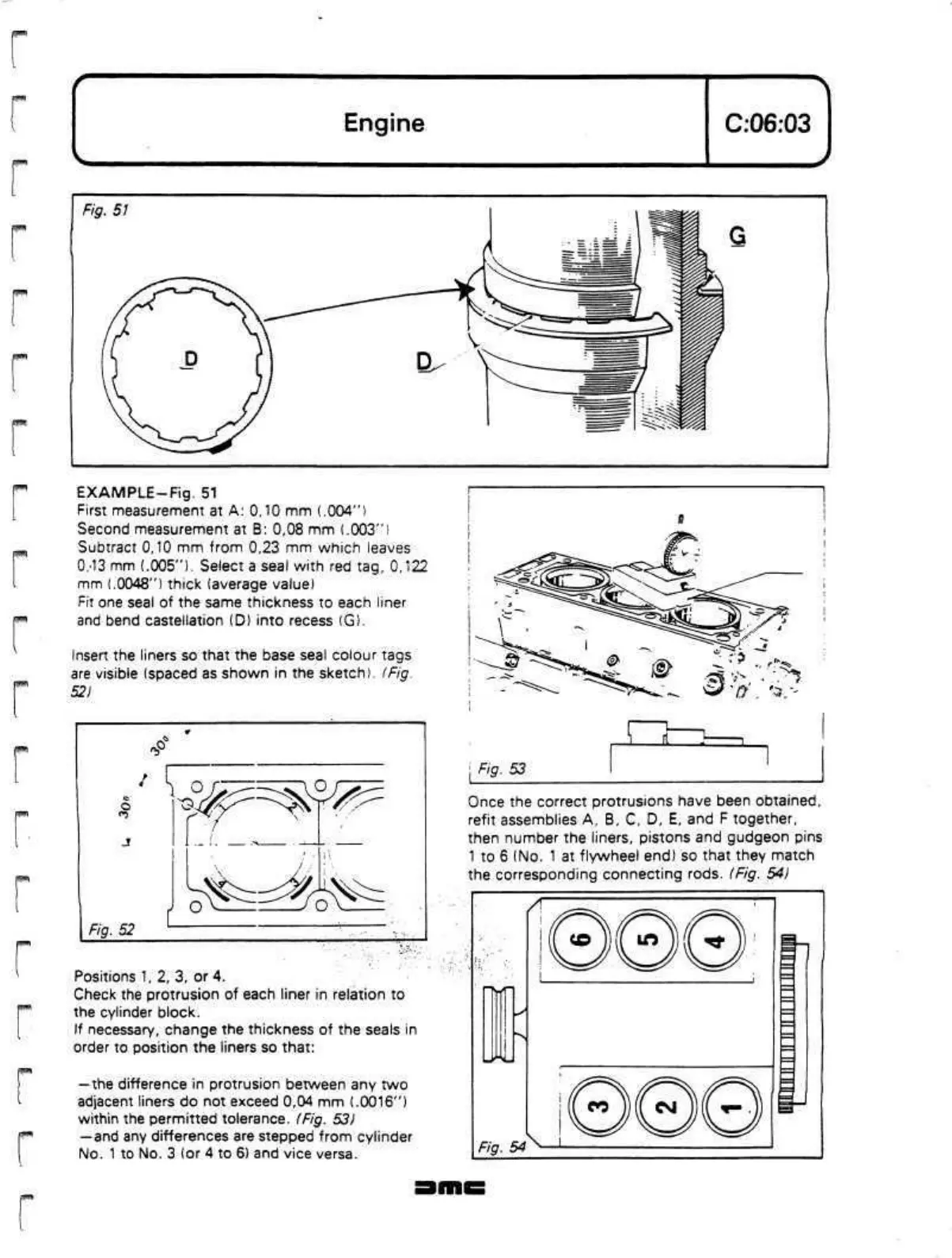

EXAMPLE-Fig.

51

First measurement at A: 0,10 mm

(.004")

Second measurement at B: 0,08 mm

(.003")

Subtract 0,10 mm from 0,23 mm which leaves

0/13

mm (.005"). Select a seal with red tag, 0,122

mm (.0048") thick (average value)

Fit one seal of the same thickness to each liner

and bend castellation (D) into recess (G).

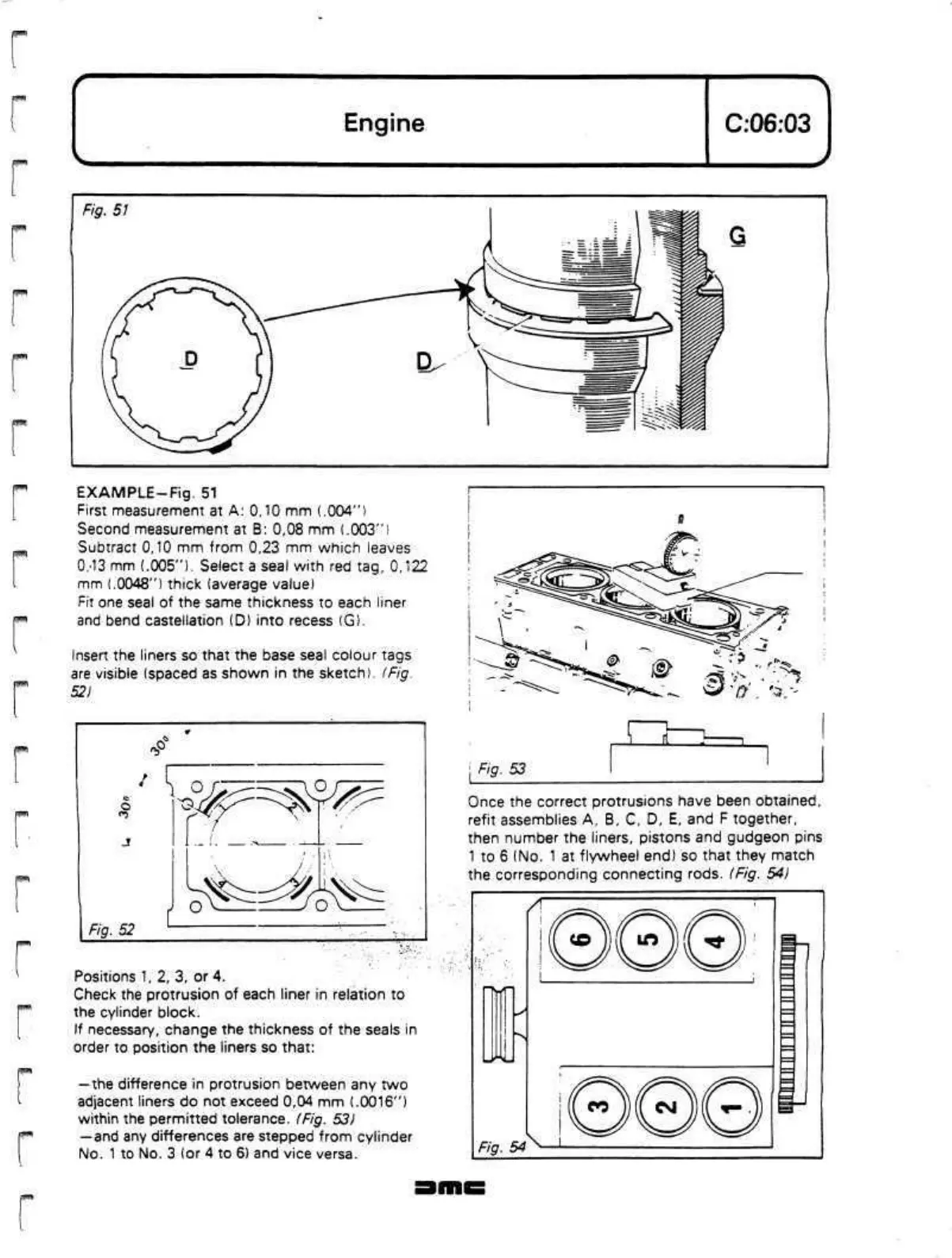

Insert the liners so that the base seal colour tags

are visible (spaced as shown in the sketch). (Fig.

52)

-P

^EE^*^

Fig. 52

Positions 1, 2, 3, or 4.

Check the protrusion of each liner in relation to

the cylinder block.

If necessary, change the thickness of the seals in

order to position the liners so that:

—the difference in protrusion between any two

adjacent liners do not exceed 0,04 mm (.0016")

within the permitted tolerance. (Fig. 53)

— and

any differences are stepped from cylinder

No.

1

to No. 3 (or 4 to 6) and vice versa.

Once the correct protrusions have been obtained,

refit assemblies A, B, C, D, E, and F together,

then number the liners, pistons and gudgeon pins

1 to 6 (No. 1 at flywheel end) so that they match

the corresponding connecting rods. (Fig. 54)

Loading...

Loading...