C:06:02

Engine

OVERHAULING-Fig.

38

Clean gasket faces on cylinder heads and cylinder

block using paint stripper (protect oil holes) 4 and

5.

Take care not to let any foreign matter enter the

oilways which could block the rocker arm jet holes

and lead to excessive wear of cam lobes and

rocker arm fingers.

Clean inside the cylinder block, particularly the

locating flanges for the liner base seals and

crankshaft.

Extract the cylinder head locating roll pins (C) and

(D).

Check condition of:

oil pump

and cylinder heads; check their gasket faces for

truth (resurfacing not permitted)

Grind in the valves and re-cut the valve seats.

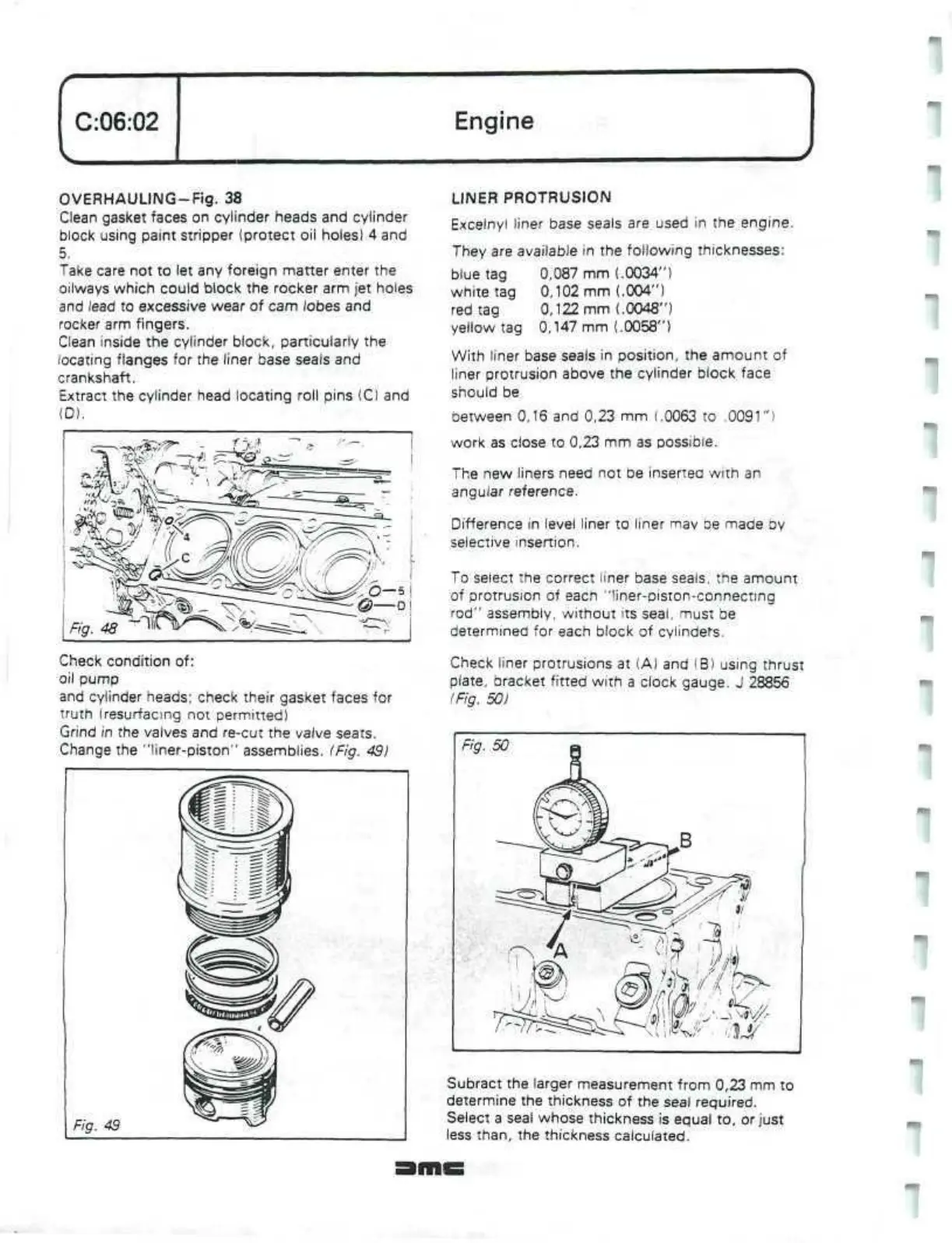

Change the "liner-piston" assemblies. (Fig. 49)

LINER PROTRUSION

Excelnyl liner base seals are used in the engine.

They are available in the following thicknesses:

blue tag 0,087 mm (.0034")

white tag 0,102 mm

(.004")

red tag

~

0,122 mm (.0048")

yellow tag 0,147 mm (.0058")

With liner base seals in position, the amount of

liner protrusion above the cylinder block face

should be

between 0,16 and 0,23 mm (.0063 to .0091")

work as close to 0,23 mm as possible.

The new liners need not

oe

inserted

with

an

angular reference.

Difference in level liner to liner

mav

De made by

selective insertion.

To select the correct liner base seals, the amount

of protrusion of each "liner-piston-connecting

rod"

assembly, without

its

seal,

must be

determined for each block of cylinders.

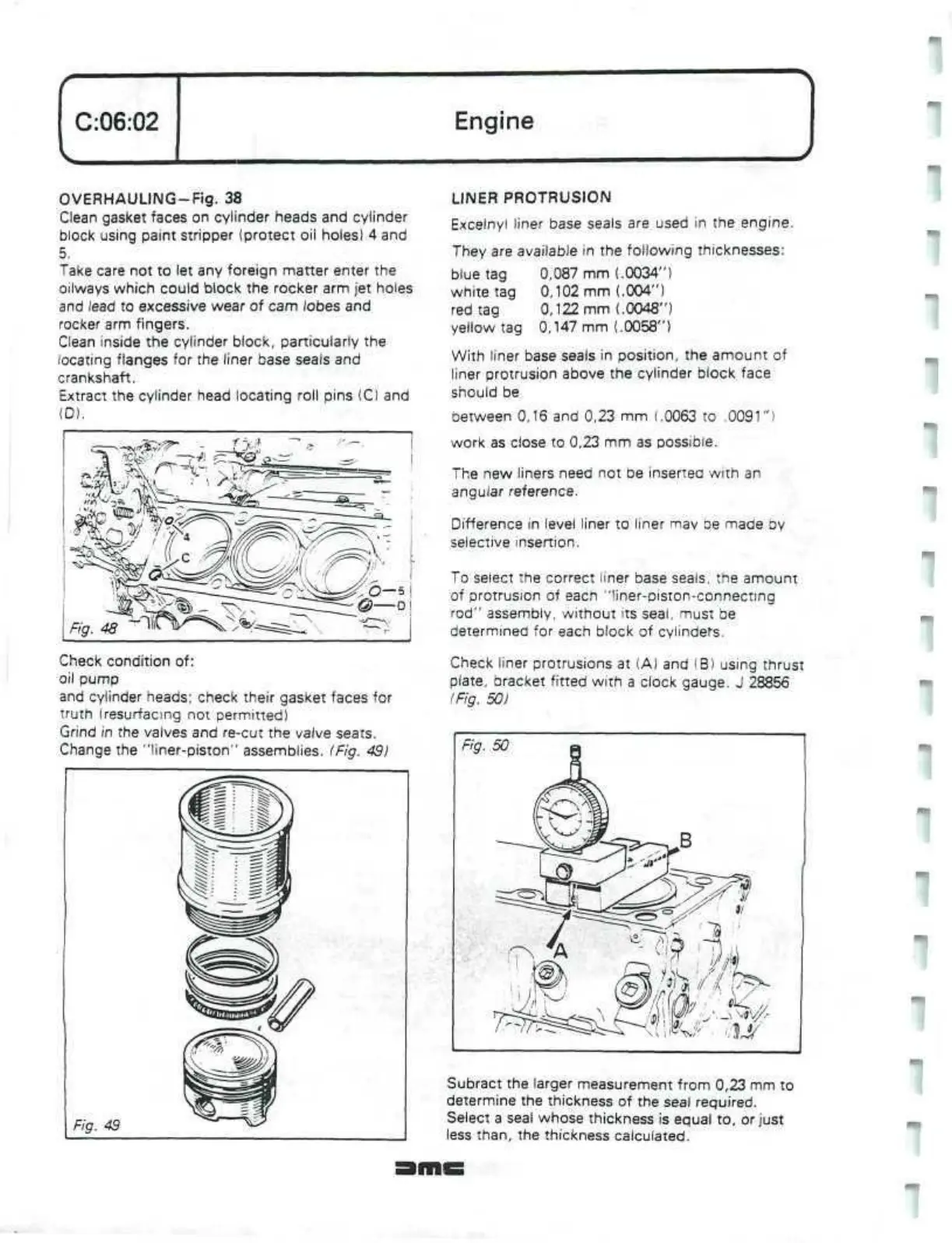

Check liner protrusions at (A) and !B) using thrust

plate,

bracket fitted with a clock gauge. J 28856

(Fig. 50}

Fig. 50

Subract the larger measurement from 0,23 mm to

determine the thickness of the seal required.

Select a seal whose thickness is equal to, or just

less

than,

the thickness calculated.

Loading...

Loading...