Liners—Pistons

CHANGING

The engine need not be removed for this

operation,

furthermore, it is possible to change

one individual "liner-piston" assembly.

It is not necessary to remove the timing cover and

timing gear when one or more "liner" and

"piston"

assemblies belonging to one bank of

cylinders

(LH

or RH) have to be changed.

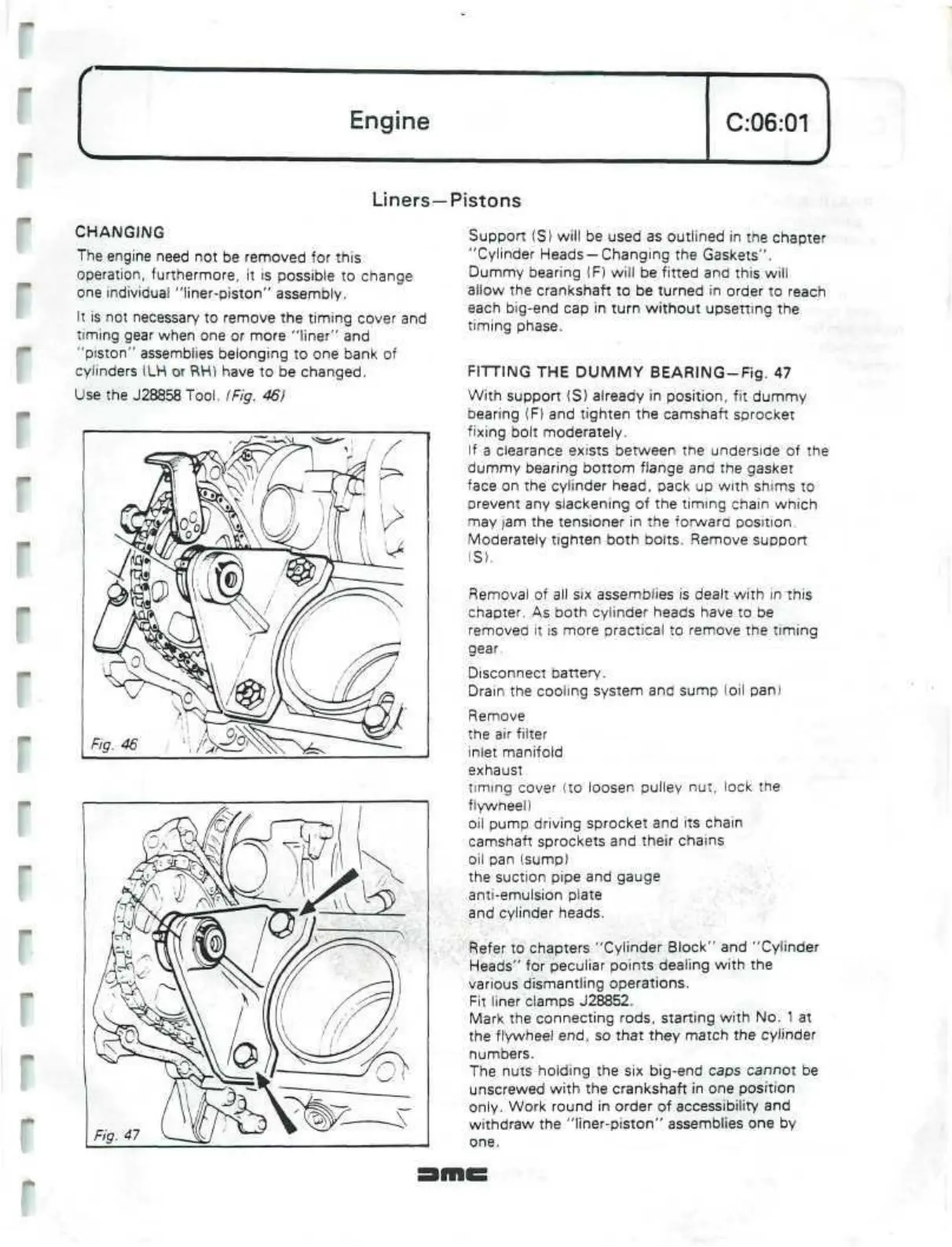

Use the

J28858

Tool.

(Fig. 46)

-

f

Support (S) will be used as outlined in the chapter

"Cylinder Heads

—Changing

the Gaskets".

Dummy bearing (F) will be fitted and this will

allow the crankshaft to be turned in order to reach

each big-end cap in turn without upsetting the

timing phase.

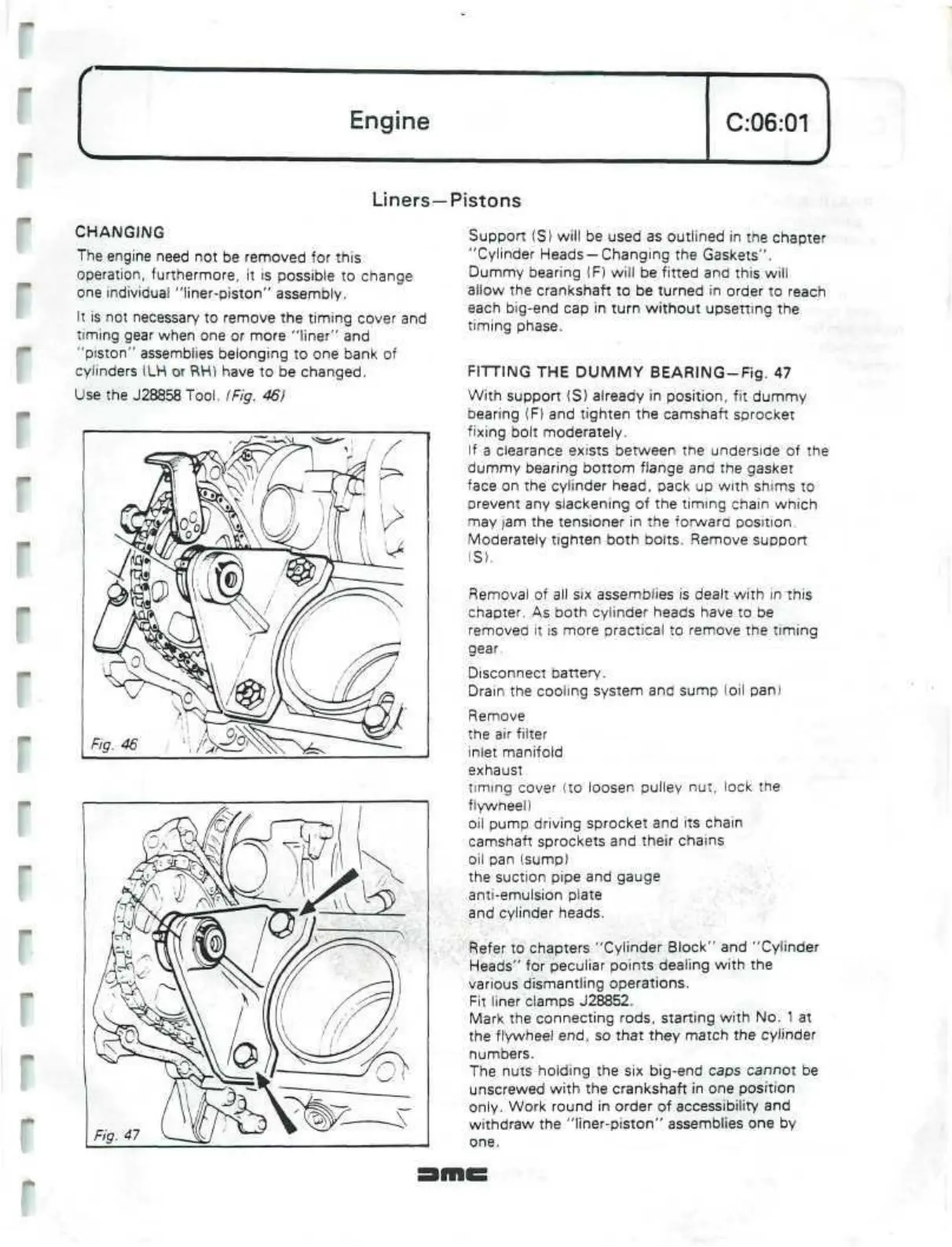

FITTING THE DUMMY

BEARING-Fig.

47

With support (S) already in position, fit dummy

bearing (F) and tighten the camshaft sprocket

fixing bolt moderately.

If a clearance exists between the

undersiae

of the

dummy bearing bottom flange and the gasket

face on the cylinder head, pack up

with

shims to

prevent any slackening of the timing chain which

may jam the tensioner in the forward position.

Moderately tighten both bolts. Remove support

IS).

Removal of all six assemblies

is

dealt with in this

chapter. As both cylinder heads have to be

removed it is more practical to remove the timing

gear.

Disconnect battery.

Drain the cooling system and sump (oil pan)

Remove

the

air

filter

inlet manifold

exhaust

timing cover (to loosen pulley nut, lock the

flywheel)

oil pump driving sprocket and its chain

camshaft sprockets and their chains

oil pan (sump)

the suction pipe and gauge

anti-emulsion plate

and cylinder heads.

Refer to chapters "Cylinder Block" and "Cylinder

Heads" for peculiar points dealing with the

various dismantling operations.

Fit liner clamps J28852.

Mark the connecting rods, starting with No. 1 at

the flywheel end, so that they match the cylinder

numbers.

The nuts holding the six big-end caps cannot be

unscrewed with the crankshaft in one position

only. Work round in order of accessibility and

withdraw the "liner-piston" assemblies one by

one.

Loading...

Loading...