L

W^

pW}

mfy

py^l

rpftl

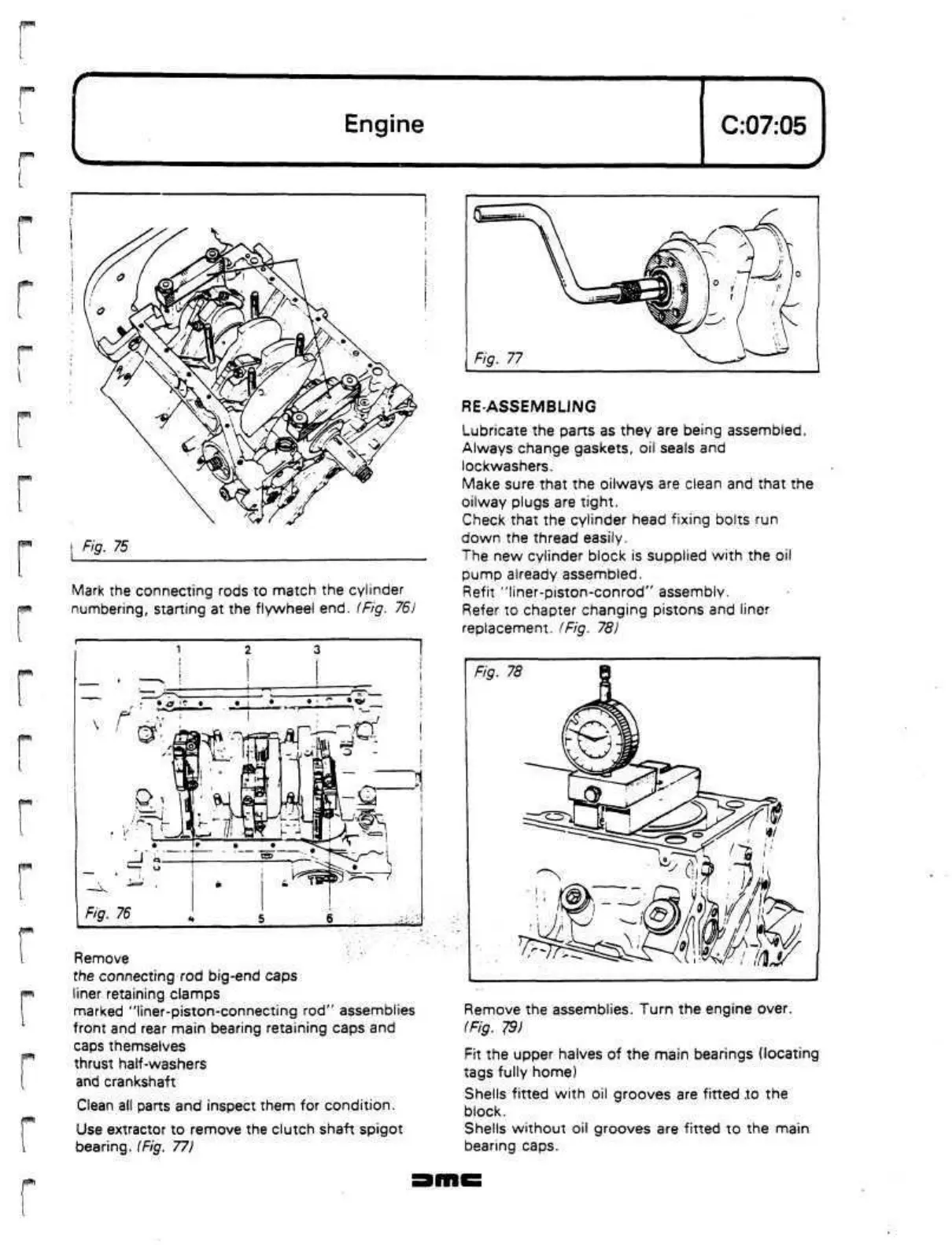

Fig. 75

Mark the connecting rods to match the cylinder

numbering, starting at the flywheel end. (Fig. 76)

Lubricate the parts as they are being assembled.

Always change gaskets, oil seals and

lockwashers.

Make sure that the oilways are clean and that the

oilway plugs are tight.

Check that the cylinder head fixing bolts run

down the thread easily.

The new cylinder block is supplied with the oil

pump already assembled.

Refit

"liner-piston-conrod"

assembly.

Refer to chapter changing pistons and liner

replacement. (Fig. 78)

Remove

the connecting rod big-end caps

liner retaining clamps

marked "liner-piston-connecting rod" assemblies

front

and rear main bearing retaining caps and

caps themselves

thrust

half-washers

and crankshaft

Clean all parts and inspect them for condition.

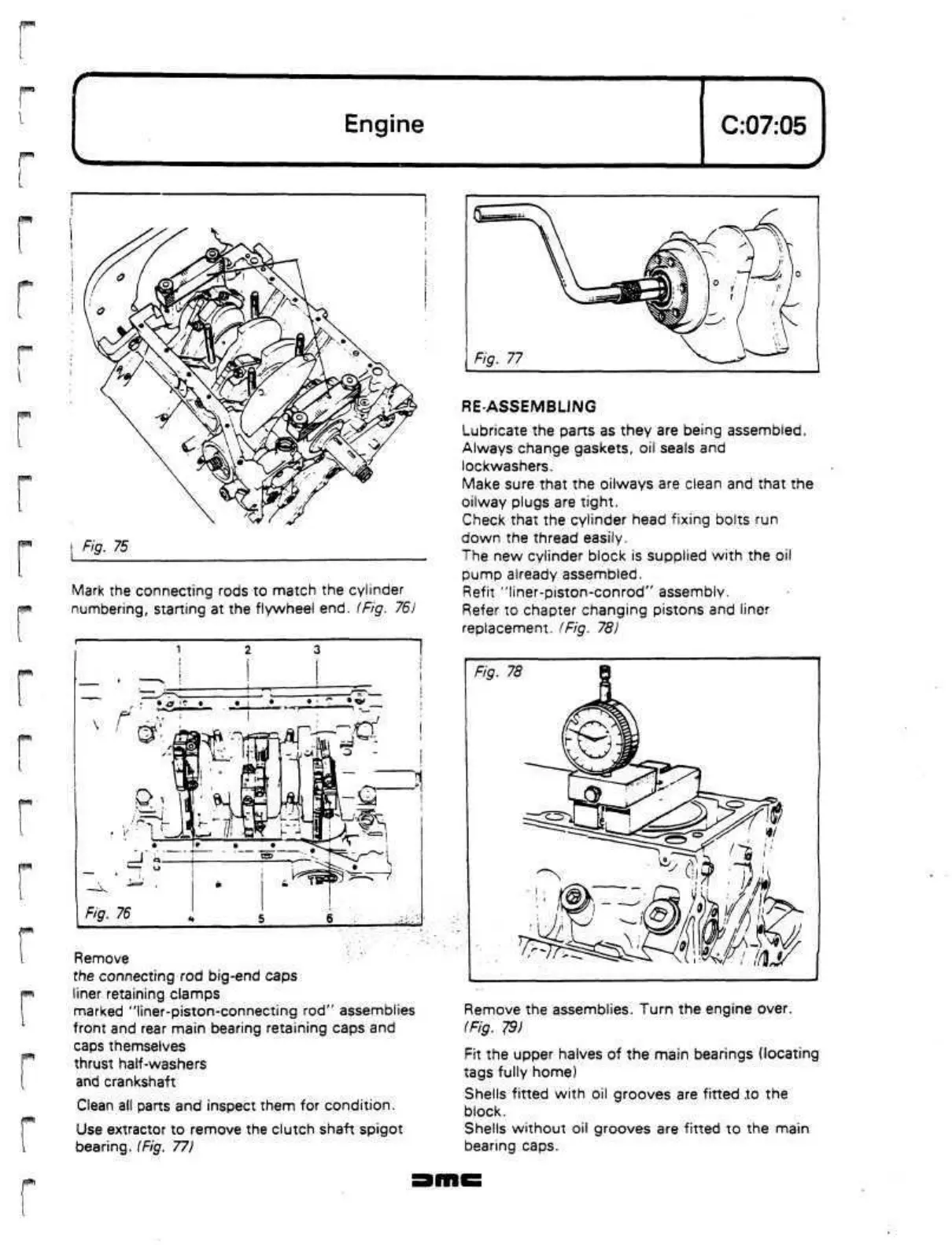

Use extractor to remove the clutch shaft spigot

bearing.

(Fig.

77)

Remove the assemblies. Turn the engine over.

(Fig. 79)

Fit the upper halves of the main bearings (locating

tags fully home)

Shells fitted with oil grooves are fitted

.to

the

block.

Shells without oil grooves are fitted to the main

bearing caps.

Loading...

Loading...