NOTE:

The arm has LH and RH threaded ends to

assist adjustment.

The LH threaded end is identified by a groove (7)

on the ball joint. Disconnect the HT wires from

the distributor.

Free the lower casing rearwards to clear the air

intake elbow rings and lift it at the back to pass

over the distributor cap. Remove the lower casing

and disconnect the vacuum pipes on the

distributor.

REFITTING

Change all seals. There

is

a plastic seal at the

eibow

end of the air channel and an "0" ring at

the lower casing end

in

the connecting rings.

Connect up the vacuum pipes.

Offer up the casing.

Screw

in

bolt (4) first to enable capscrews (3)

to line up with their holes.

Tighten bolt (4) then capscrews (3). (Fig.

118)

Re-connect

The HT wires to the distributor cap

All fuel unions

The

idle

speed air pipe, after greasing the "0"

ring

in the lower casing

The idle speed control

The throttle arm ball joint, locking

it

correctly

with

the clip (8) (Fig.

119)

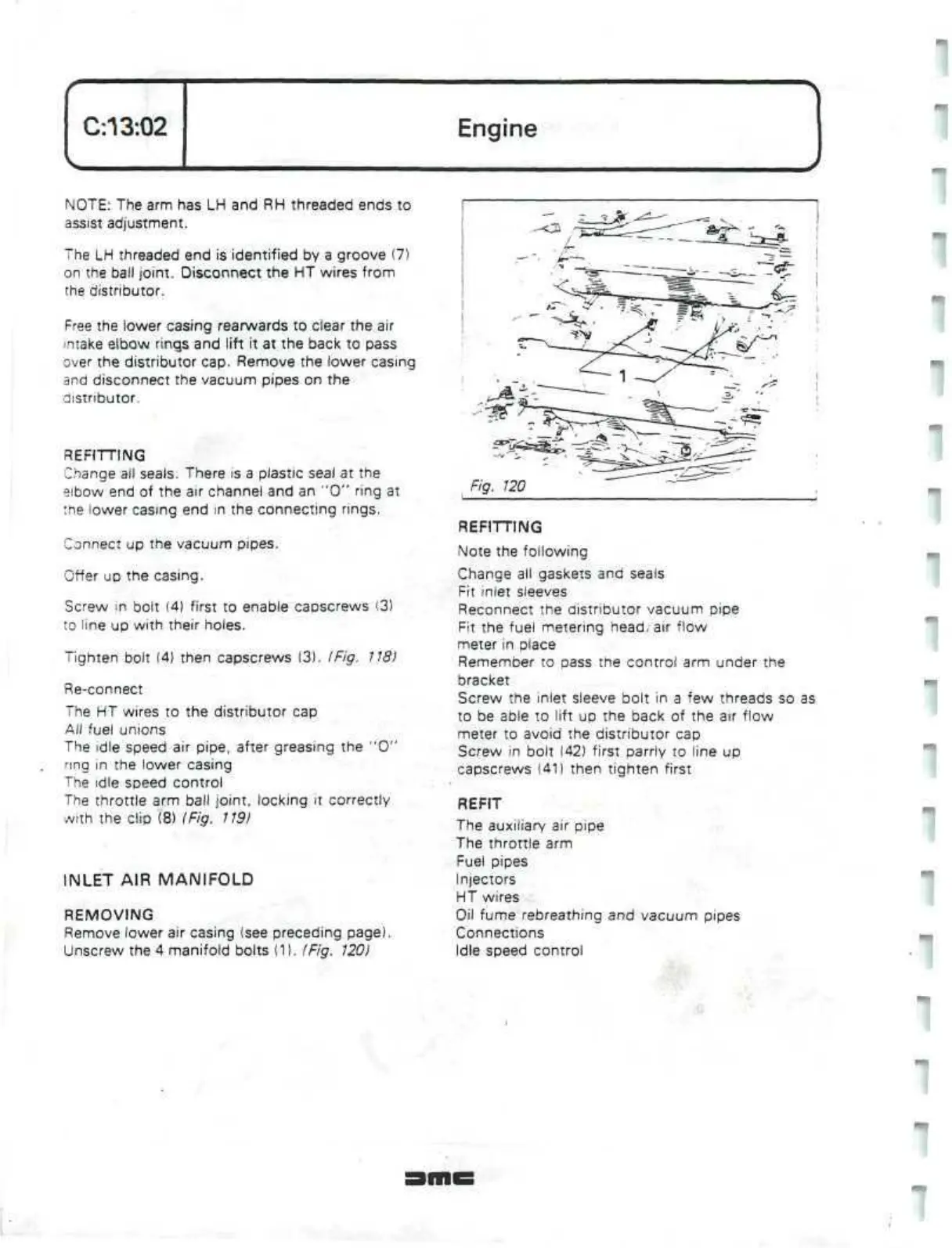

INLET

AIR MANIFOLD

REMOVING

Remove lower air casing (see preceding page)

Unscrew the 4 manifold bolts (1). (Fig. 120)

Fig. 120

REFITTING

Note the following

Change all gaskets and seals

Fit inlet sleeves

Reconnect the distributor vacuum pipe

Fit the fuel metering head/air flow

meter in place

Remember to pass the control arm under the

bracket

Screw the inlet sleeve bolt in a few threads so as

to be able to lift up the back of the

air

flow

meter to avoid the distributor cap

Screw in bolt (42) first parrly to line up

capscrews (41) then tighten first

REFIT

The auxiliary air

pipe

The throttle arm

Fuel pipes

Injectors

HT wires

Oil fume rebreathing and vacuum pipes

Connections

Idle speed control

Loading...

Loading...