Chapter 8 Load Cell Module AS02LC

8- 13

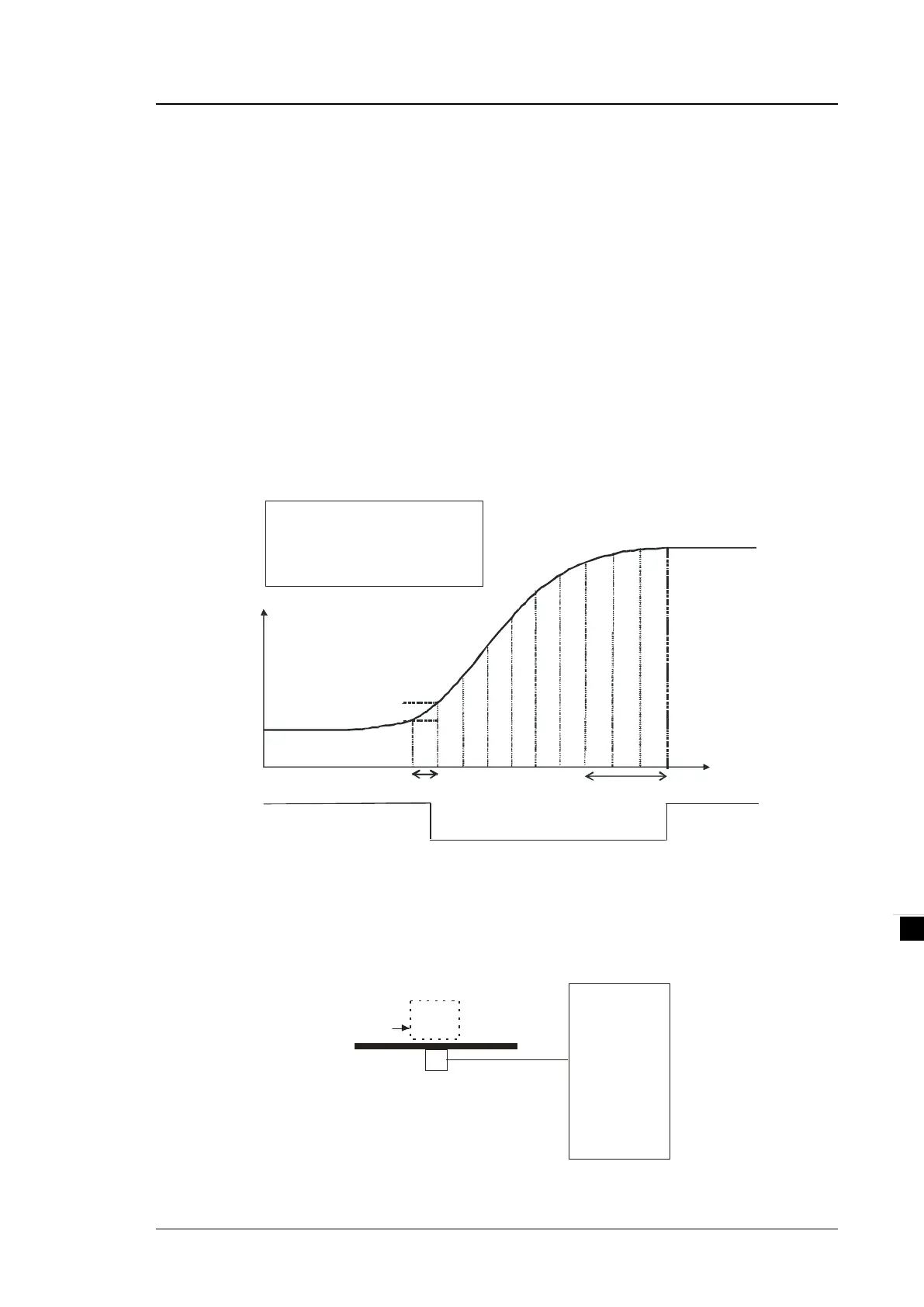

2. Checking stability

When an object is placed on a load cell, you can check whether the present weight of the object is in a

specified stability range.

If the weight measured is in the specified stability range, the corresponding bit is set to 1.

If the weight measured exceeds the specified stability range, the corresponding bit is set to 0 until the

number of objects weighed in the stability range reaches the setting.

Example: the measurement time set is 10 ms, the number of weights measured in a stability range is 10, and

the stability range is 1000 g. If a variation exceeds 1000 g, the corresponding bit is set to 0. If the variations

within 100 ms (10×10 ms) are within 1000 g, the corresponding bit is set to 1. You should determine whether

the present weight measured is in the stability range before you perform control actions.

t

k

m

t

>k

m

<k

>k

>k

>k

>k

>k

< k

<k

b it

Bit in th e stab il it y range

△ : Va ria tion s in a ve ra ge we ights

t: Measur em en t tim e set by use rs

k: Stab il i ty range set by use rs

m: Num be r o f wei gh ts me a su re d in

a stabi l ity ra n ge

Time

Ave rage wei gh t

△

△>k

△< k

△>

△>

k

△>k

△> k

△>k

△>k

△< k

△<k

k

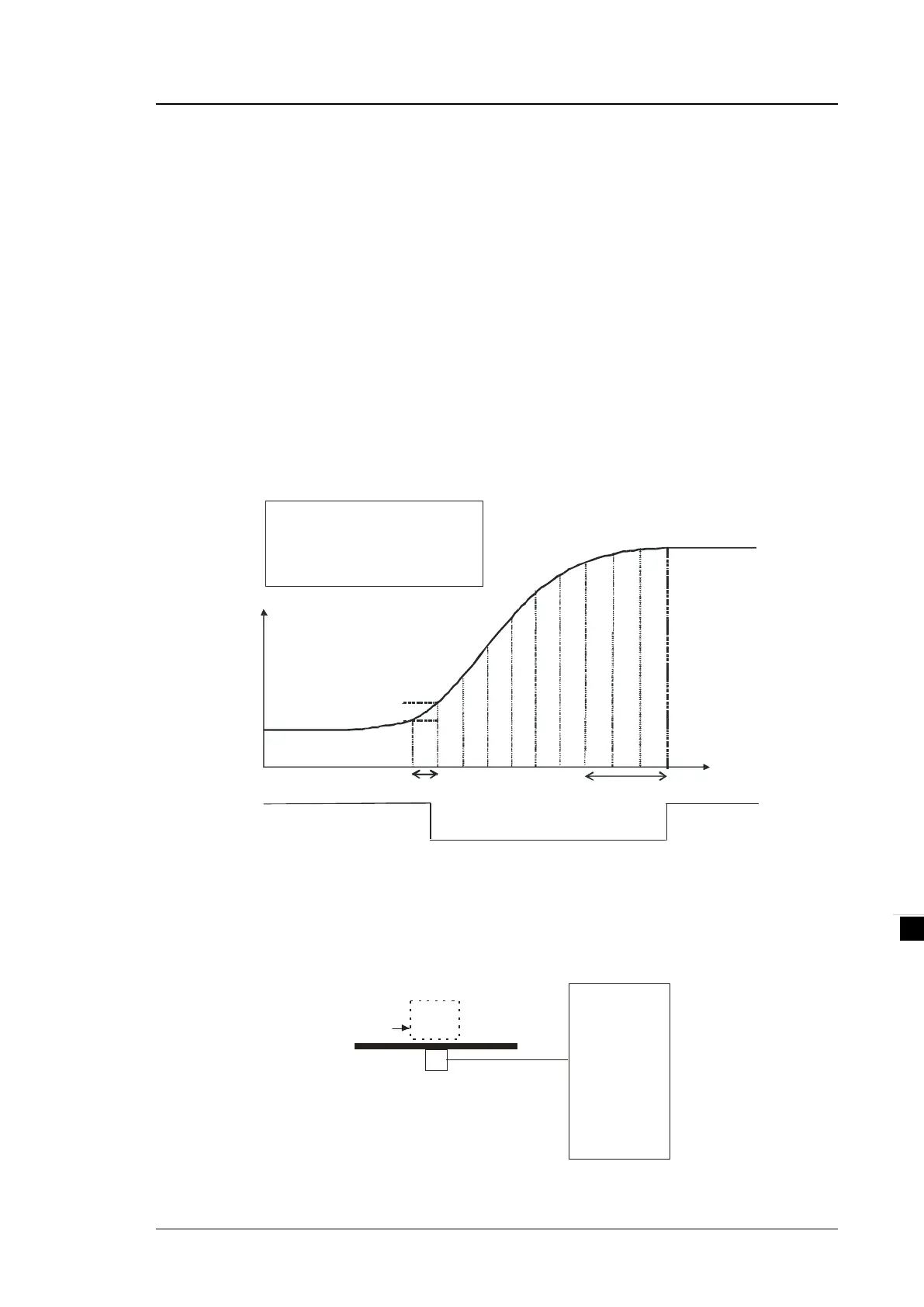

3. Determining zero point

If an object is removed from the load cell, the corresponding bit is set to 1, and you can perform the next

control action. If a weight measured is in the specified zero range, the corresponding bit is also set to 1.

Ch 1

CH 2

Loa d cell

No o b ject

Loading...

Loading...