46

ENGLISH

5. Release the trigger and raise the stapler from the

worksurface.

NOTE: The tool motor returns to full speed automatically

without the contact trip

7

beingdepressed.

6. Repeat steps 3–5 to actuate the nextstaple.

Multi-Angle Contact Trip (Fig. J)

The contract trip

7

has three notches to allow the user to locate

the wire depending on the desired angle they want to staple,

allowing the user to drive the staple at angle to the wood grain

up to 45degrees.

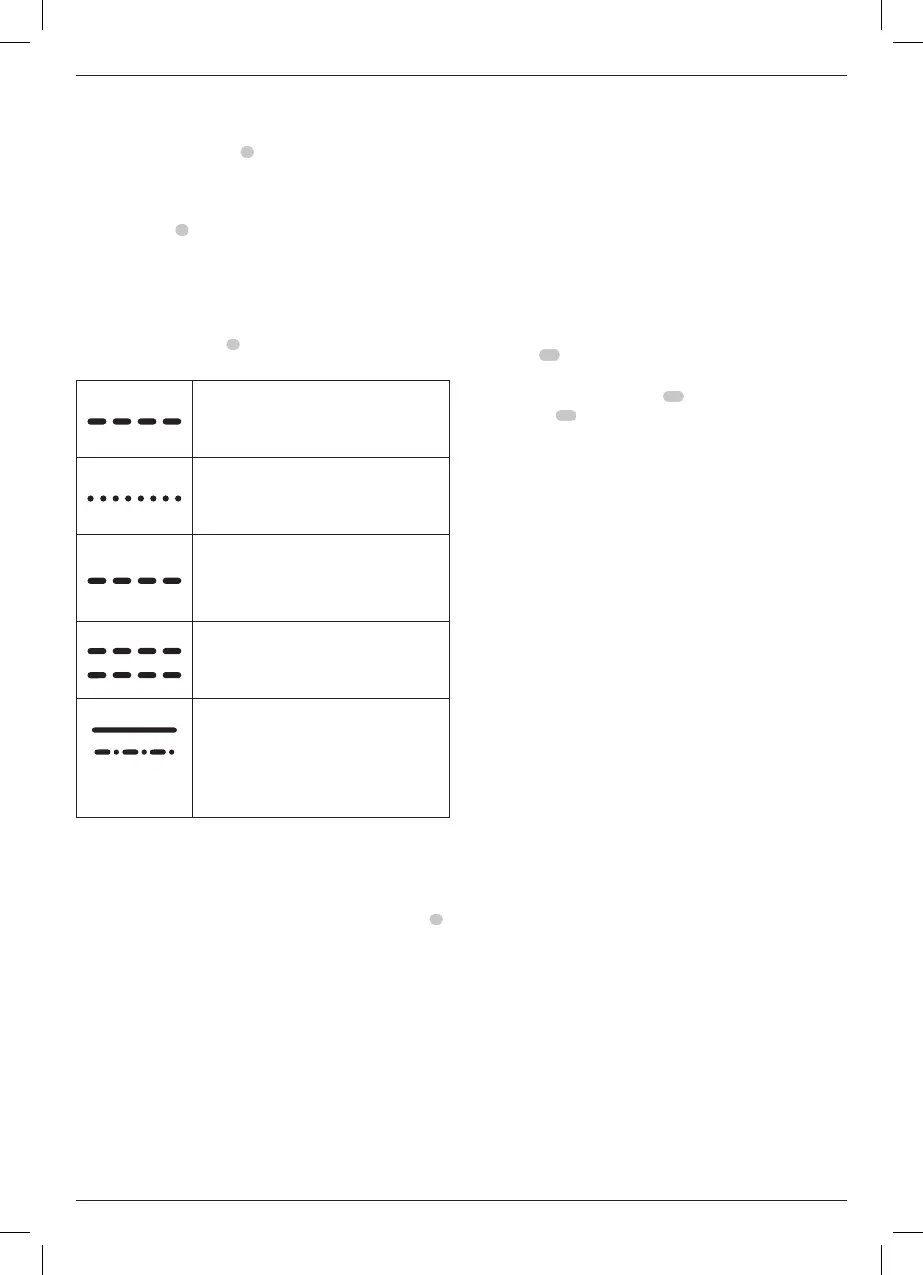

Headlights/LED Indicator (Fig. A)

There are LED work lights

9

located on the front of the tool on

each side of themagazine.

LOW BATTERY

Replace battery with a chargedpack.

HOT PACK

Let the battery cool or replace it with a

coolpack.

JAM/STALL CONDITION

Rotate the stall release lever torelease.

Refer to Stall Release or Clearing a

JammedStaple.

HOT TOOL (Both LEDs Flashing)

Let the tool cool down before

continuinguse.

or any other

combination.

ERROR

Reset tool by removing and reinserting

battery pack or cycling trigger lock-off.

If error code persist, take tool to an

authorised

servicecenter.

Stall Release (Fig. K)

If the stapler is used in harder material where all available

energy in the motor is used to drive a fastener, the tool may

stall. The driver will not complete the drive cycle and the jam/

stall indicator will flash. Rotate the tool free stall release lever

8

on the tool and the mechanism willrelease.

NOTE: The tool will disable itself and not reset until the battery

pack has been removed and reinserted. If the driver does not

automatically return to the home position, proceed to Clearing

a Jammed Staple. If the unit continues to stall please review

the material and fastener length to be sure that it is not too

rigorous an application. The stapler could also be overheated

and needs time to cool before furtheruse.

Clearing a Jammed Staple (Fig. A, L)

WARNING: To reduce the risk of serious personal

injury, disconnect battery pack from tool before

making any adjustments, changing accessories,

servicing, or moving the tool. Such preventative safety

measures reduce the risk of starting the toolaccidentally.

CAUTION: When removing a jammed staple, DO

NOT orient the stapler with the nose up or with the

battery foot up. Positioning the stapler this way makes

the jammed staple or pieces of the staple more likely to

be ingested into the stapler. If any portion of a staple is

ingested into the tool, the staple should be retrieved by

removing the topcap.

If a staple becomes jammed in the nosepiece, keep the tool

pointed away from you and follow these instructions toclear:

1. Remove battery pack from tool and engage trigger lock-off.

2. After laying the tool on its side, slide the spring-loaded

pusher

12

to the base of the magazine to lock it into place

and unload staplestrip.

3. Rotate the magazine release

11

and rotate the

magazine

10

forward.

4. Remove jammed/bent staple, using pliers ifnecessary.

CAUTION: If any portion of a staple is ingested into

the tool, the staple should be retrieved by removing the

topcap.

5. If the driver is in the down position, rotate the stall release

lever on the top of thestapler.

NOTE: If the driver will not reset after rotating the stall

release lever, manually resetting the blade with a long screw

driver may benecessary.

6. Rotate the magazine back into position under the nose of

the tool and close the magazine releaselever.

7. Reinsert batterypack.

NOTE: The tool will disable itself and not reset until the

battery pack has been removed andreinserted.

8. Reinsert staples into magazine (refer to Loading theTool).

9. Release the pusherlatch.

10. Disengage the trigger lock-off when ready to

continuestapling.

NOTE: Should staples jam frequently or the driver continually

fail to reset, have tool serviced by an authorised

servicecentre.

Cold Weather Operation

When operating tools at temperatures below freezing:

1. Keep tool as warm as possible prior touse.

2. Actuate the tool 10 or 15 times into scrap lumber

beforeusing.

Hot Weather Operation

Tool should operate normally. However, keep tool out of direct

sunlight as excessive heat can deteriorate bumpers and other

rubber parts resulting in increasedmaintenance.

MAINTENANCE

Your

power tool has been designed to operate

over a long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon proper tool

care and regularcleaning.

Loading...

Loading...