41

ENGLISH

DE0730 Target card (fig. I3)

The target card locates and marks the laser beam

as the beam crosses the card, thus enhancing the

visibility of the projected line. The laser beam passes

through the red plastic surface and is reflected by

the reflective rear side of the card. Supporting easy

use during plumb and level adjustment, the card is

marked with inch and metric scales, and has

magnets at the top to hold it to ceiling track or steel

studs.

Wall mount (fig. I4)

The wall mount may also be used as a base to

provide extra stability for the tool.

Optional accessories

Consult your dealer for further information on the

appropriate accessories.

These are:

- DE0772 Digital laser detector

- DE0734 Grade rod

- DE0736 Tripod

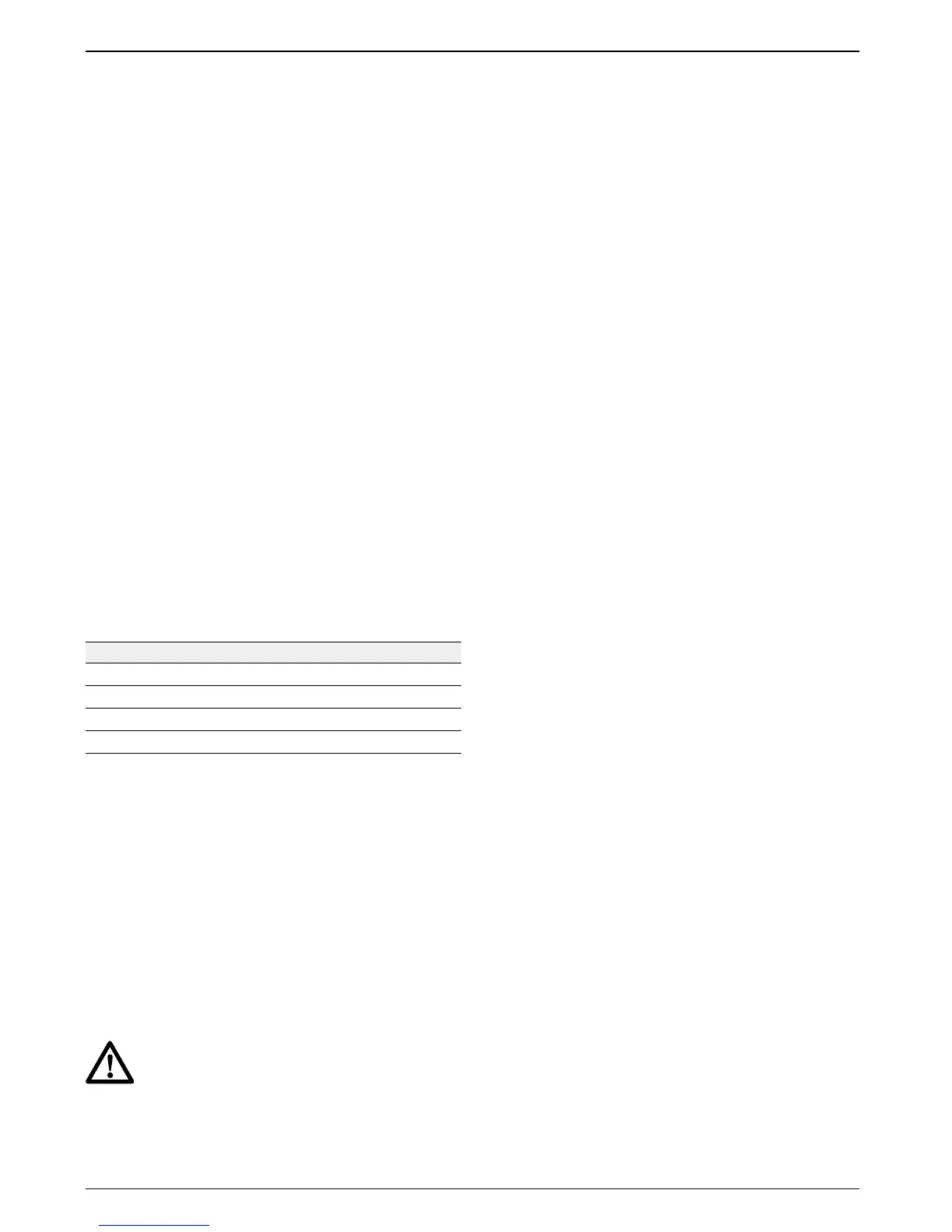

Battery packs

Voltage NiCd NiMH

9.6 DE9061 DE9036

12 DE9071 DE9037

14.4 DE9091 DE9038

18 DE9095 DE9039

Maintenance

Your DEWALT Power Tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

Field calibration check

The field calibration checks must be performed

securely and accurately to make a correct diagnosis.

Whenever an error is registered, have the tool

calibrated by a qualified repair agent.

Always have the laser head calibrated by

a qualified repair agent.

Level checks

The following checks are performed to check the

calibration of laser head for level alignment.

• Place the tool in an area at about 15 m from a

vertical surface.

• With the tool in a tripod set-up, adjust the tool for

a level application.

To perform a level check of the X-axis:

• Position the tool so that the X-axis is parallel with

the vertical surface.

• Switch on the tool and rotate the head until the

laser dot appears on the vertical surface.

• Mark the centre of the laser beam. Switch off the

tool.

• Switch off the tool and rotate it 180° so that the

X-axis is parallel with the vertical surface the

other way around.

• Switch on the tool, rotate the head and once

again mark the centre of the laser dot on the

surface. Switch off the tool.

• Measure the difference between the markings.

• If the difference between the markings is 3.2 mm

or less, the laser head is properly calibrated.

• If the difference between the markings is more

than 3.2 mm, the laser head must be calibrated.

To perform a check of the Y-axis:

• Position the tool so that the Y-axis is parallel with

the vertical surface.

• Following the same procedure as described above,

mark the centre of the laser dot on the surface with

the tool in this position, after which the tool is rotated

180° to mark the centre of the laser dot once again.

• Measure the difference between the markings.

• If the difference between the markings is 3.2 mm

or less, the laser head is properly calibrated.

• If the difference between the markings is more

than 3.2 mm, the laser head must be calibrated.

Plumb check

The following check is performed to check the

calibration of laser head for plumb alignment.

• Place the tool in an area at about 1 m from a

vertical surface.

• With the tool in a floor set-up, adjust the tool for

a plumb application.

• Mark the top and bottom of the vertical surface

using a plumb bob.

• Switch on the tool and align the laser beam with

the lower marking.

• Using the remote control, move the head until the

laser beam is at the upper marking.

Loading...

Loading...