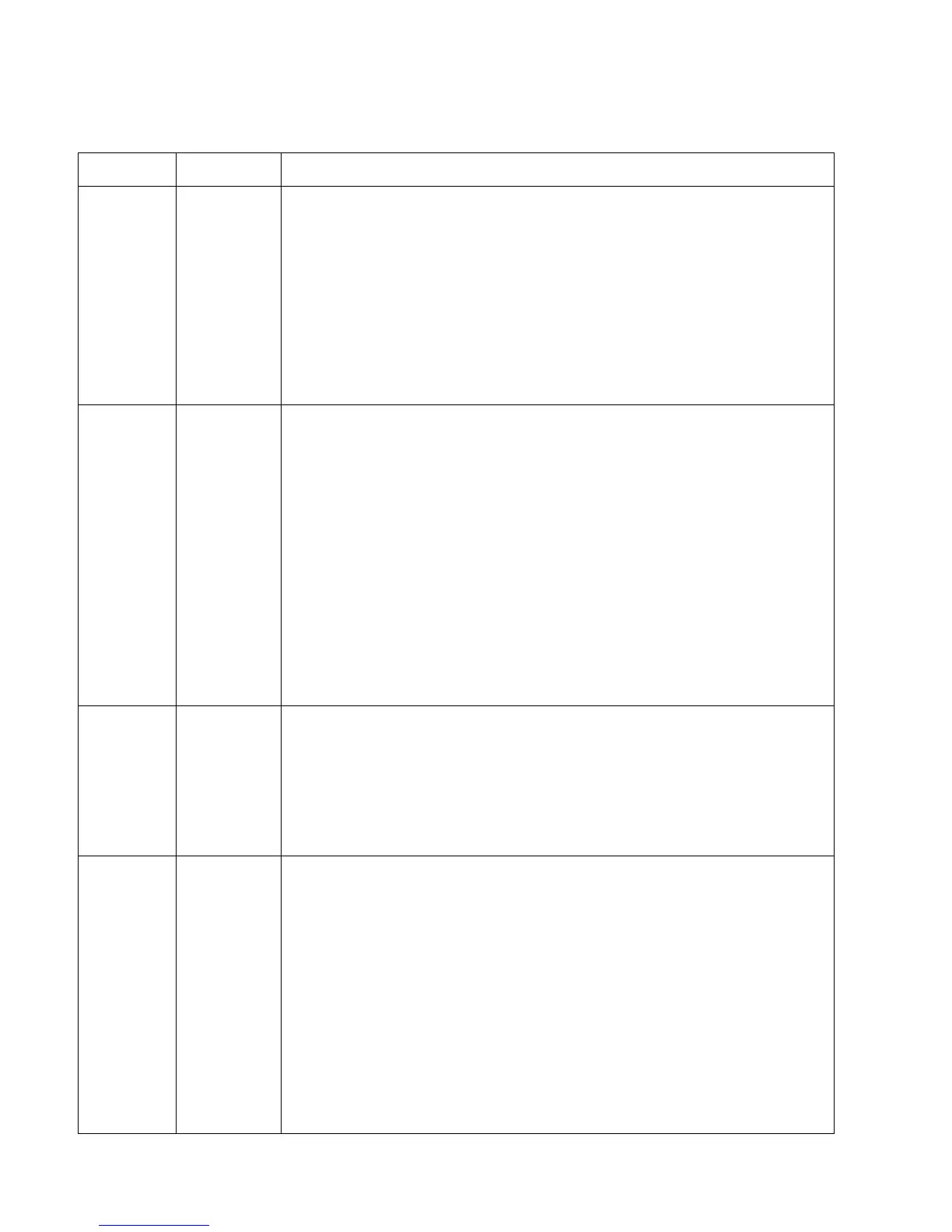

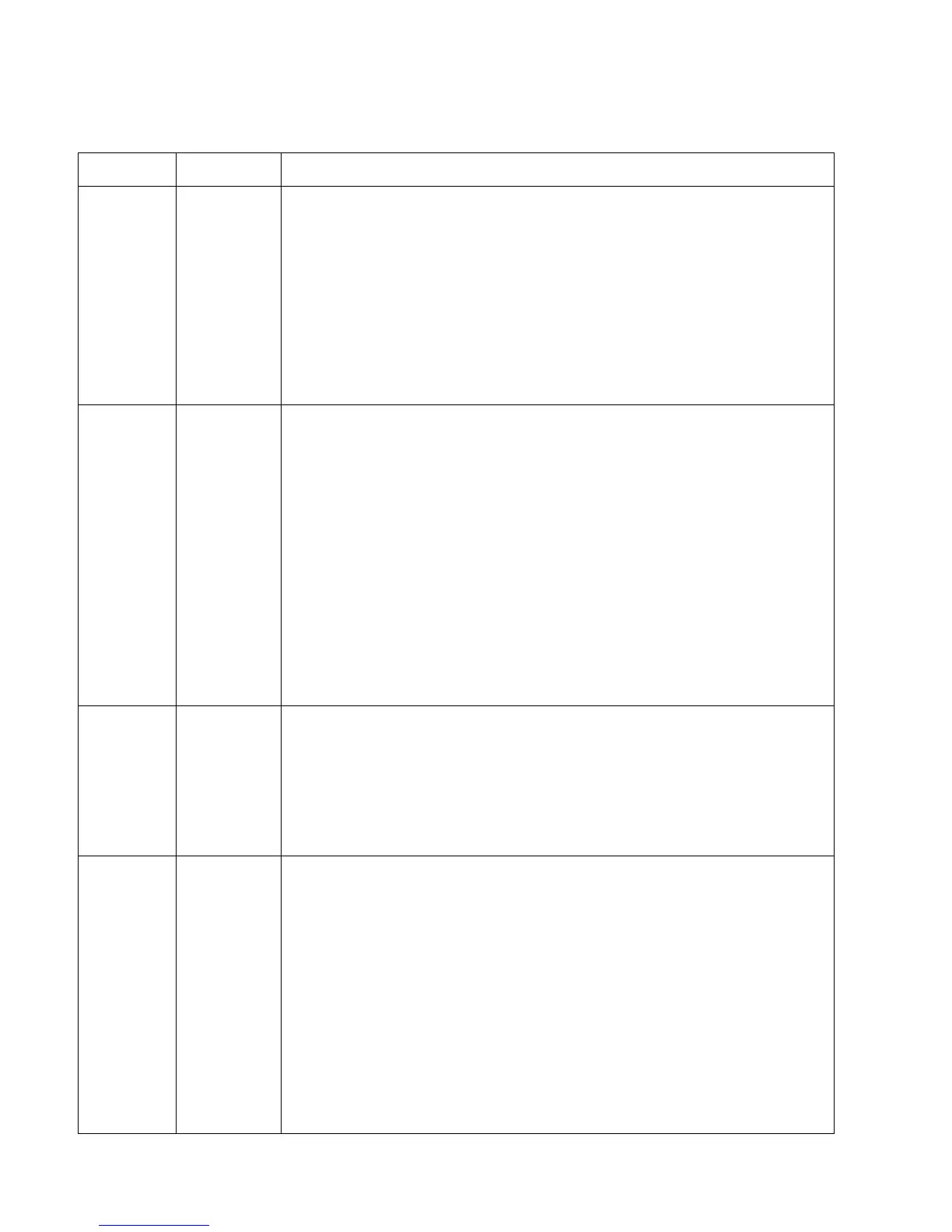

Troubleshooting

Problem Symptom Possible Solutions

Hydraulic

Pump

No Oil

Flow

• CHECK OIL LEVEL IN RESERVOIR. If oil level is low, check for

leaks in system.

• CHECK BELT TENSION. Tighten if needed. Replace belt if

necessary.

• CHECK FOR SHEARED KEY ON PUMP SHAFT. Replace key.

• CLUTCH NOT FUNCTIONING. See clutch section.

• INTERNAL PUMP DAMAGE. Have pump repaired or replaced.

• CHECK PRESSURE LINE AT PUMP TO SEE IF OIL IS MOVING.

• CHECK TO SEE IF SUCTION HOSE COLLAPSES IN SUCTION

Hydraulic

Pump

No Oil

Pressure

• VALVE NOT FUNCTIONING. Check for disconnected wires at

solenoid.

• CHECK FOR POSSIBLE LEAKS IN SYSTEM. Repair blown

hoses.

• CHECK FOR MALFUNCTIONING SWITCH. Replace broken

switches.

• PRESSURE RELIEF IS BROKEN ALLOWING OIL TO BYPASS

SYSTEM. Replace pressure relief.

• PRESSURE SEAL ON PUMP IS BROKEN OR WORN. Replace.

• BELTS OR CLUTCH MAY BE SLIPPING. Tighten belts.

• PRESSURE RELIEF MAY BE SET TOO LOW.

CAUTION: PRESSURE EXCEEDING 2,600 PSI CAN DAMAGE

THE PUMP.

Clutch Does Not

Engage

• CHECK FOR BLOWN FUSE. Replace.

CAUTION: FUSE SHOULD NOT EXCEED 30 AMPS

• CHECK WIRE TO CLUTCH. Insure there are no breaks or shorts.

• CHECK FOR BAD SWITCHES IN SYSTEM. Replace.

• CHECK FOR BAD MAGNETIC COIL. Use jumper from positive

battery terminal to check coil. Replace coil if necessary.

Belt(s) Jumps Off

Pulley

• BELTS TOO LOOSE. Tighten belts.

• CHECK FOR EXCESSIVE BELT WEAR. Replace worn belts.

• CHECK FOR LOOSE PUMP BRACKET. Tighten loose bolts.

Replace broken bolts.

• CHECK ALIGNMENT OF CLUTCH AND CRANKSHAFT

PULLEYS. Re-align pulleys.

• CHECK CRANKSHAFT PULLEY FOR LOOSE OR BROKEN

BOLTS. Tighten loose bolts. Replace broken bolts.

• CHECK ALIGNMENT OF IDLER PULLEY AND THE CONDITION

OF IDLER PULLEY BEARINGS. Re-align idler pulley. Replace

worn or broken bearings.

• MAKE SURE THAT BELTS ARE NOT CRACKED OR WORN.

Loading...

Loading...