ICE CUBE MAKERS “SPRAYERS” SYSTEM

Last Update: 04/04/2011

C

C

C

B

B

B

L

L

L

i

i

i

n

n

n

e

e

e

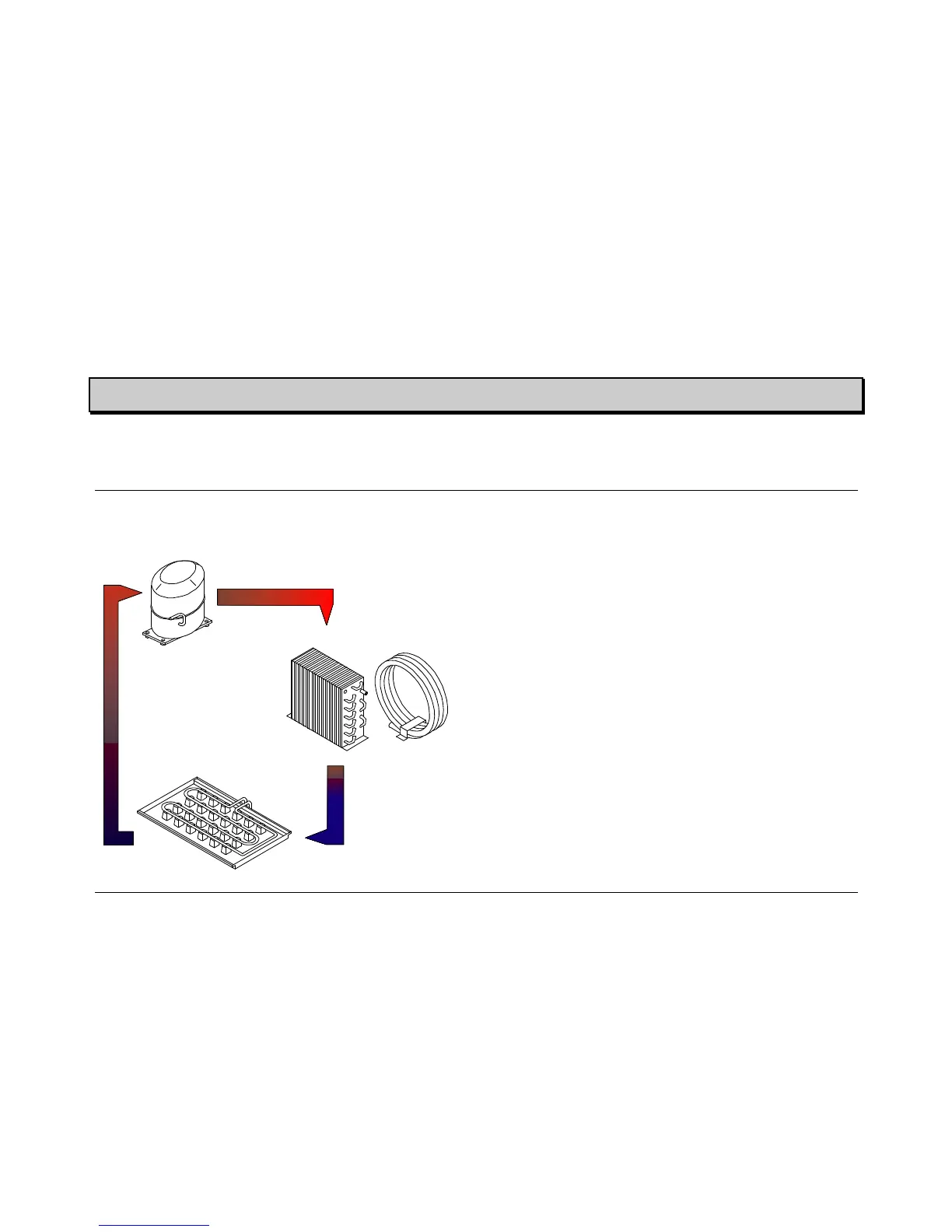

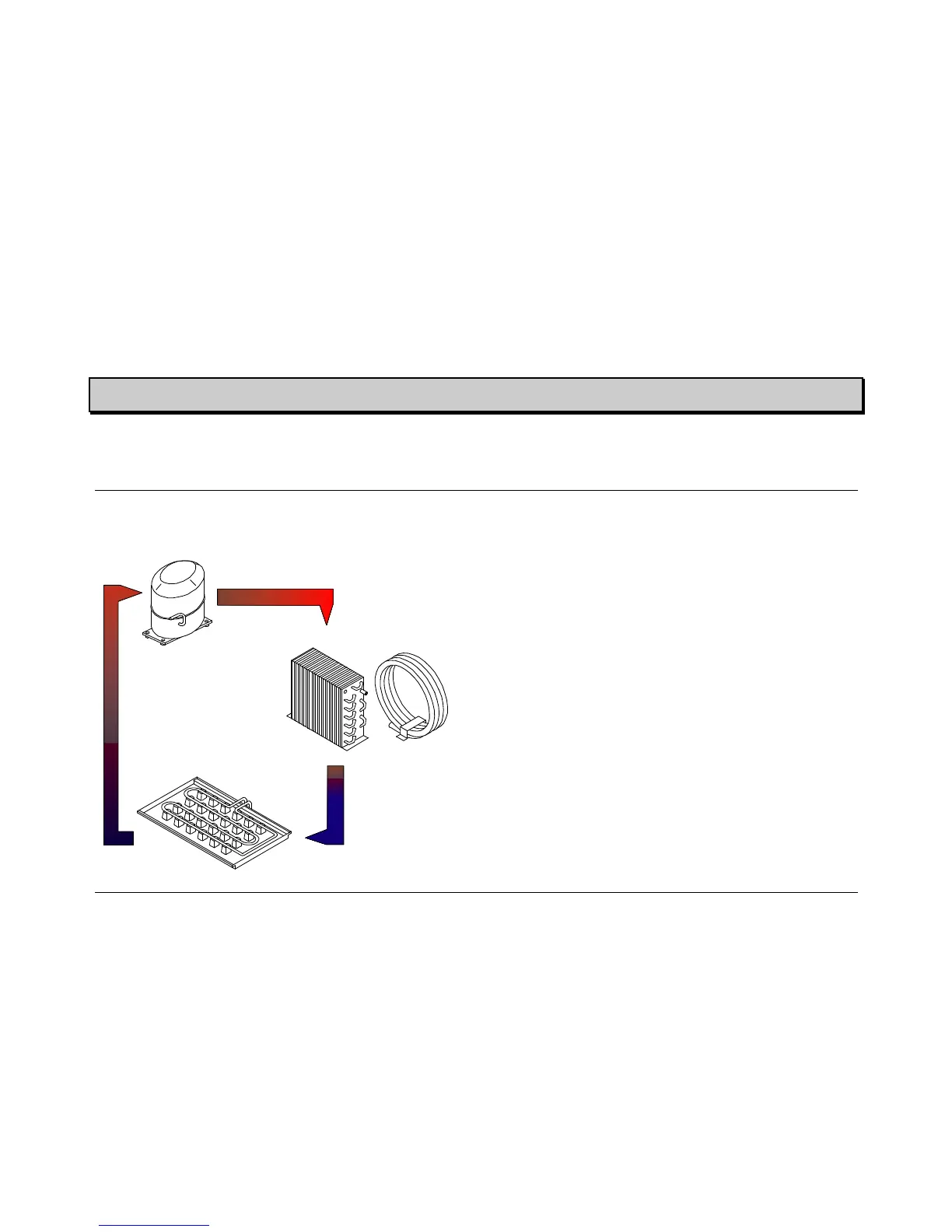

The following diagram shows the main concepts of the ice cube

makers working (‘sprayers’ system).

Condenser

Air

Water

Evaporator

Each ice maker uses the properties of compression and

expansion of the liquefiable gases; its main principle is that each

change of bodies state is got by producing or absorbing heat.

The compressor sucks up the gases, generated by the

evaporation, and compresses them, increasing their

temperature and pressure.

A condenser, made up of a series of tubes (refrigerated by

cold water or ventilated air), carries away the heat, comprised in

the gas from the compressor and helps, in this way, the gas

liquefaction.

The refrigerating fluid, now in liquid state, circulates, then, in an

evaporator that permits an optimal heat exchange with the out-

room, by taking away calories and producing ice, which is got by

means of the freezing of the water sprayed in the cubes forms

by the spray-bar.

The working of this machine is cyclical: ice cubes are produced

during the first phase and fall in the built-in bin during the

second phase.

Loading...

Loading...