PAGE2OF2 REV. B 05/01 FILE # DS0026 DOC#PT-100-DS

1. Allow PT-100 to warm up for 5 minutes.

2. Depress the reset toggle momentarily.

3. Zero the display by alternatingly turning the zero knob

andmomentarily pressingthe resettoggleuntil thedis-

play reads 00.0.

4. Press the R-cal button on the back of the unit. Press

the reset toggle to zero the display. Repeat this pro-

cess several times to assure a repeatable value. The

display value (R-cal # X .005 = tolerance

R-cal # plus & minus tolerance = range)

should be within .5% of the value recorded on the bot-

tom of the unit.

EXAMPLE: R-cal = 81.0

81.0 X .005 = .40

80.6 to 81.4 = range

5. If anyof theproceduresin steps 2-4donot producethe

expected results, the unit should be returned to DMC

forrepair andrecalibration.

6. SERVICE

Repairand calibration servicesfor thePT-100 WireCrimp

Pull Tester is available from Daniels Manufacturing Corpora-

tion. Spare parts are also available.

Shoulditbe necessary to returnthe unit forservice, please

ship tothe address onthis datasheet, freightprepaid. Enclose

aletter, or purchaseorderwith company name,address, phone

number, the individual to be contacted and the reason for re-

turn.

COPYRIGHT©2001 ALLRIGHTSRESERVED

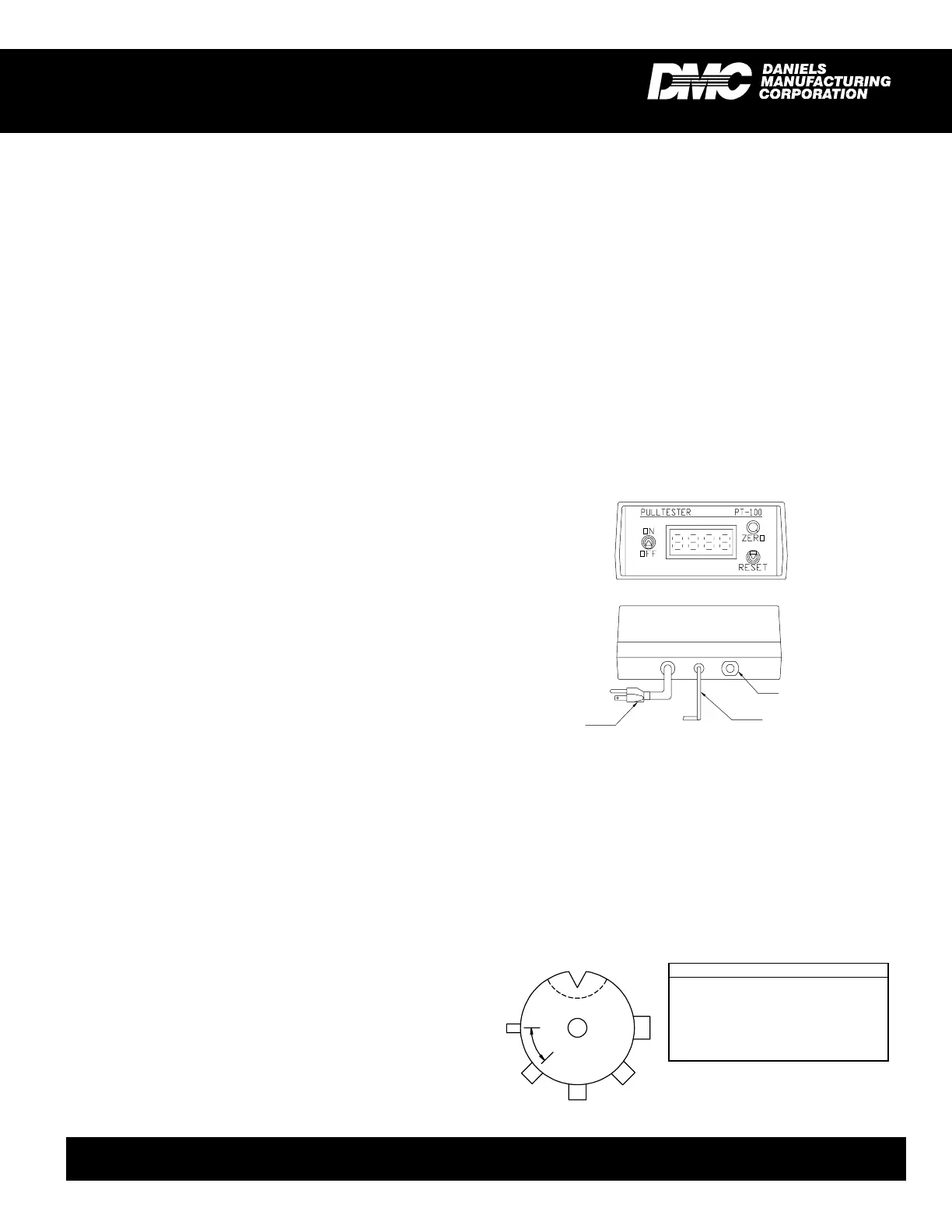

NOTE: This option is made of heavier

duty material and is useful specifically

for testing ring terminals. It also offers

a universal "V" groove for testing non-

standard terminal sizes.

the amount of force exerted on the crimp. As the force is

increased the display will continue to update the reading until

the force is no longer increasing. (Usually this is the point at

which the crimp is pulled loose, or the wire breaks.)

Upon completion of the test, release the wire and press

the reset button on the display prior to the next test.

Best results are obtained with the PT-100 using a slow,

consistent motion when pulling the lever. A quick, or hesitant

motion can cause the wire to slip within the self tightening

cams and the terminal also may become unseated within the

slot.

4.CHANGING TERMINALGRIPS

CAUTION: The PT-100utilizes aprecision loadcell for

its force measurement. Care must be exercised when

changing grips not to create excessive side load on the

load cell sensor.

To change or replace the terminal grip complete the fol-

lowing steps in sequence.

1. Toprovide moreroom to workraise the rackand pinion

lever arm assembly as high as possible. Loosen the

large black knob on the left hand side of the assembly,

raise the assembly and retighten the knob.

2. Using a 9/64 in. hex key and an 11/32 in. open end

wrench, loosen and remove the 8-32 locking hex nut

from the bottom of the sensor assembly.

3. Remove the 8-32 x 1-1/2 in. screw, slip washer, termi-

nal grip and spacer from the sensor.

4. When installing the optional ring terminal grip, the re-

cessed center hole must face up for proper operation.

5. Reassemble in this order: Install slip washer on screw,

followed by the terminal grip, and spacer. Insert the

screw with this assembly through the hole in the sen-

sor.

6. Install 8-32 locking hex nut.

7. Using the hex key and open end wrench, tighten until

some effort is required to rotate terminal grip. This is

necessary to avoid play between the terminal grip and

the sensor.

8. Lower the rack and pinion lever arm assembly to its

operating level and tighten knob to secure.

5. FUNCTIONALCHECK

The PT-100 Wire Crimp Pull Tester is factory calibrated

with equipmenttraceable tothe NationalInstituteof Standards

and Technology (NIST). We recommend recalibrating the unit

at intervals not to exceed one year in duration.

The funtional check is executed using the R-cal switch

built into the unit . The R-cal switch is located on the rear of

the unit, and its R-cal value is on the sticker applied to the

bottom of the unit.

A functional check can be performed at any time:

OPTIONAL RING TERMINAL GRIP

DATASHEET

DANIELS MANUFACTURING CORP., 526 THORPE ROAD,ORLANDO, FL 32824, USA

PHONE (407) 855-6161 • FAX (407)855-6884 • WWW.DMCTOOLS.COM • E-MAIL: DMC@DMCTOOLS.COM

RING POSITION

1 Slot .200" to .03" @ .250" Depth

2 3/8" Dia. x .250" Pin

3 5/16" Dia. x .250" Pin

4 1/4" Dia. x .250" Pin

5 3/16" Dia. x .250" Pin

6 1/8" Dia. x .250" Pin

1

2

3

4

5

6

45° TYP.

LEADTOLOAD

CELL

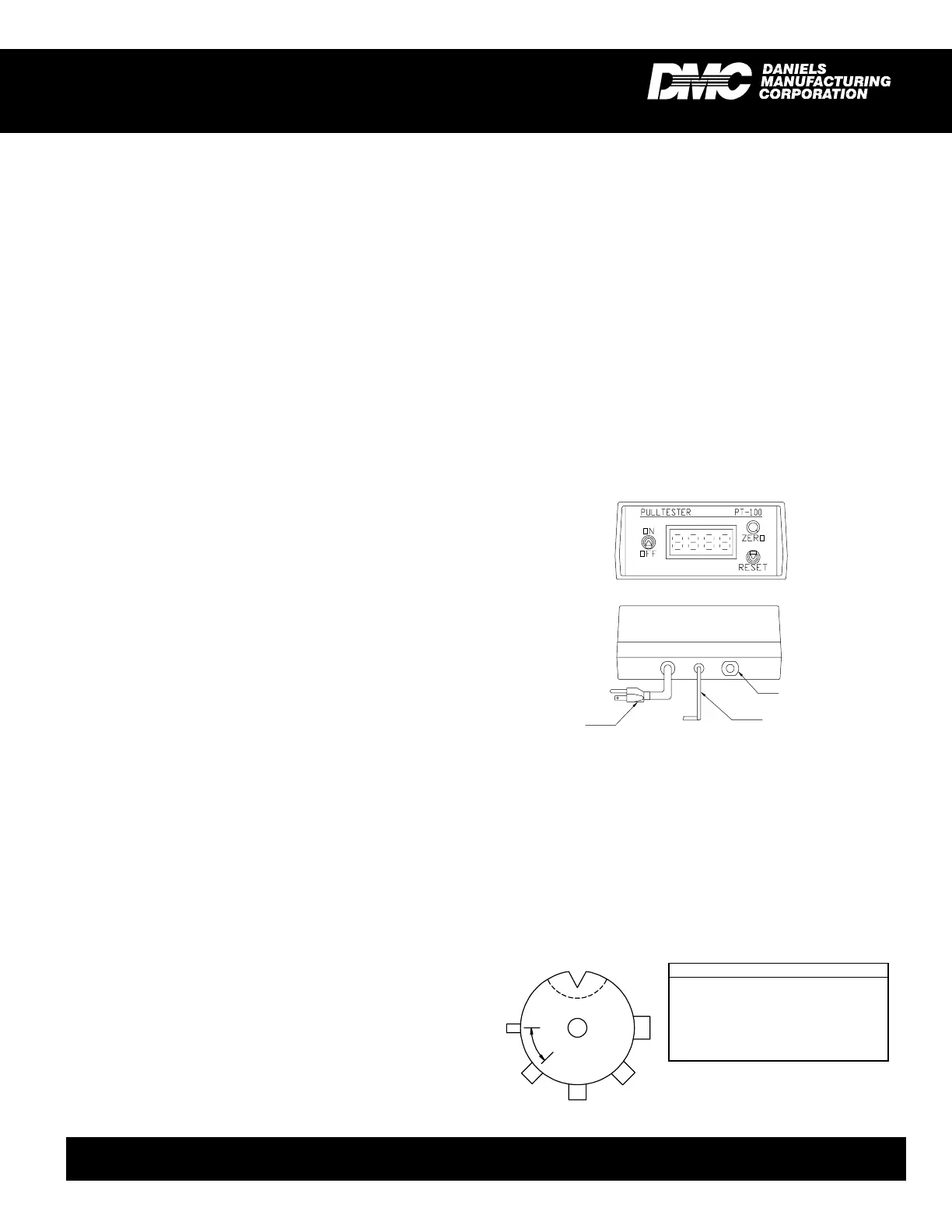

R-cal

POWER

(115 VAC)

FRONTVIEW

REARVIEW

Loading...

Loading...