3359001

©DrägerSafetyUKLimited

Edition05–March2014(Edition01–June2010)

Subject to alteration

4 Troubleshooting

Thetroubleshootingguideshowsfaultdiagnosisandrepairinformationapplicabletobreathingapparatususers.FurthertroubleshootingandrepairinformationisavailableinInstructions

forUsesuppliedwithassociatedequipment.

Wherethetroubleshootingguideshowsmorethanonefaultorremedy,carryoutrepairactionsintheorderthattheyappearinthetable.

ContactservicepersonnelorDrägerwhentheremedyinformationindicatesaservicetask,orifthesymptomremainsafterallremedyactionshavebeenattempted.

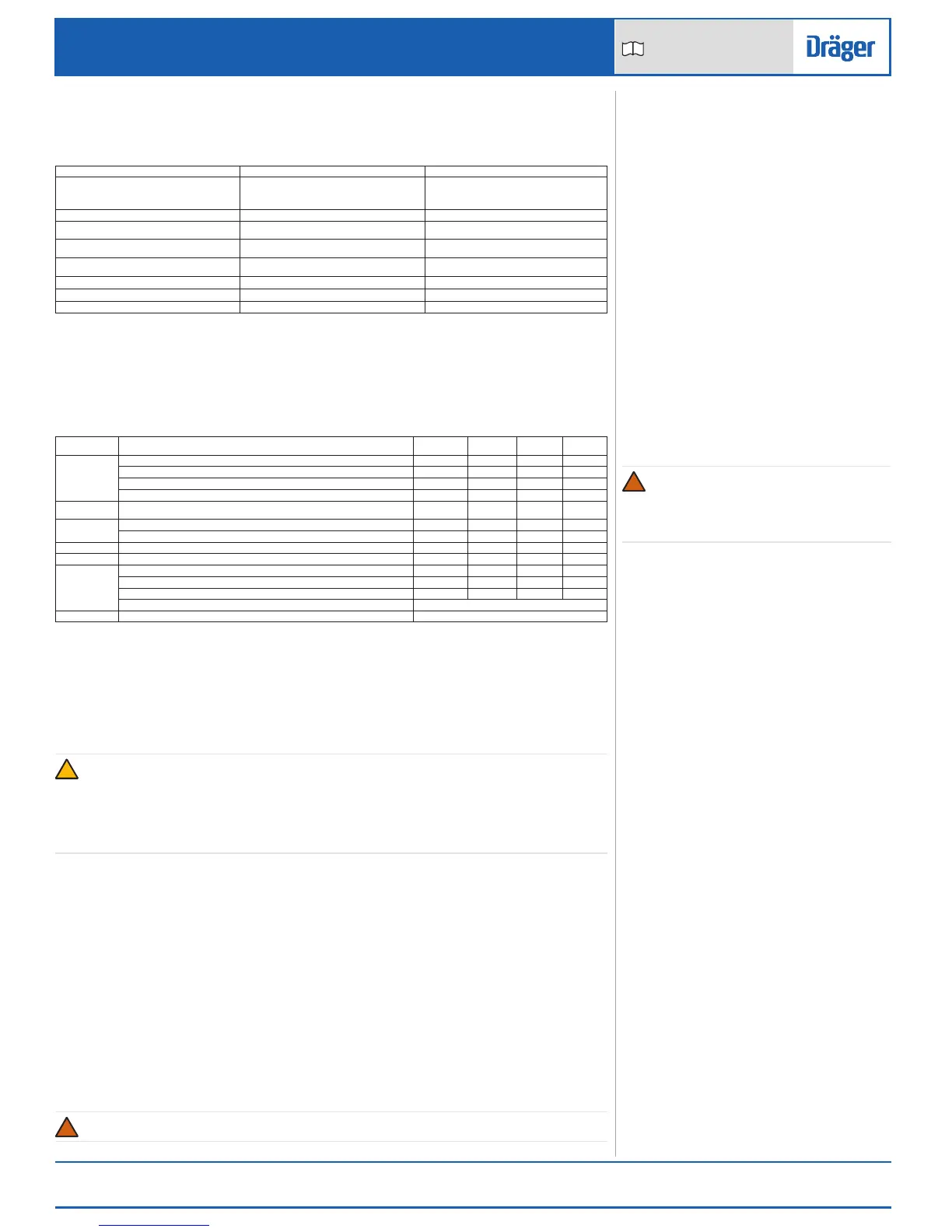

Symptom Fault Remedy

Facemaskairleak LungdemandregulatorO-ringleaking

Headstrapsnottight

Exhalationvalveleaking

Speechdiaphragmdefective

ReneworlubricateO-ring

Tighten

Servicetask

Servicetask

Unsatisfactorycommunication Speechdiaphragmdefective Servicetask

High-pressureairleakorfailedleaktest Looseordirtyconnector

Faultyhoseorcomponent

Disconnect,cleanandreconnectcouplingsandretest

Substitute user replaceable accessories and retest

Airleakfrommedium-pressurehoseconnectionatthe

rst-stageregulator(safetyreliefvalve)

FaultyO-ring,retainer,springorrst-stageregulator Servicetask

Lungdemandregulatorallowingconstantairowinto

thefacemask

Bypassbuttonengaged

Internalfault

Turnoffthebypassbutton(Fig2,Item3)

Servicetask

Highorlowmediumpressure First-stageregulatorfault Servicetask

Poorsoundingwhistle Whistledirty Cleanwhistleuteandretest

Whistlenotfunctioningcorrectly Activationmechanismfault Servicetask

Manufacturer:

DraegerSafetyUKLimited Tel +441670352891

UllswaterClose,RiversideBusinessPark Fax +441670356266

Blyth,NE244RG

UnitedKingdom Internethttp://www.draeger.com

USDistributor:

DraegerSafety,Inc. Phone 1-800-922-5518

101TechnologyDrive Fax 1-800-922-5519

Pittsburgh

PA15275 Internethttp://www.draeger.com

6 Storage

6.1 Storage preparation

● Extendtheshoulderstraps,waistbeltandtheheadharnessstrapsofthefacemask.

● Forstorage,placethefacemaskinaprotectivebag(contactDräger for supply of a

suitablebag).

● Routerubberhosesinsuchawaythatthebendradiusisnottooacuteandthehoseis

notstretched,compressedortwisted.

6.2 Storage conditions

● Storetheequipment between5°Fand 77 °F(-15°C and +25°C).Ensure that the

environmentisdry,freefromdustanddirt,anddoesnotsubjecttheequipmenttowear

ordamageduetoabrasion.Donotstoretheequipmentindirectsunlight.

● Fixthebreathingapparatus securely toanyraisedmountingpoint to prevent itfrom

falling.

7 Disposal

Disposeofusedbatteriesinaccordancewithnationalorlocalregulations.Whenrequired,

dispose of other parts of the breathing apparatus, including electrical and electronic

equipment,inlinewithanynationalorlocalenvironmentalregulations.

8 Technical data

Compressed-aircylinders:

● 30minutesto60minutescapacity

● 2216psior4500psipressure

● Aluminumorcompositematerials.

Cylinderhigh-pressureconnectors:

● 2216psiconnectortoCGA346

● 4500psiconnectortoCGA347.

Lungdemandregulatortofacemaskconnector:

● Drägerpush-inconnector.

Whistlewarning(EOST)–Activationcommencementrange:

● 2216psicylinder:600psito510psi

● 4500psicylinder:1215psito1035psi.

9 Special instructions

9.1 Use of an independent air supply (supplied airline

respirator (SAR) connection)

!

WARNING

Airqualitymustconformtothestatutoryrequirements.

Useofanairlineconnectionbyasecondperson(buddy-breather)voidsNIOSH

approval.

Thetime requiredfor the wearer to escapeto asafe area mustbe withinthe

remaining breathing time of the cylinder, taking into account the remaining air

contentinthecylinderandthebreathingrateofthewearer.

Independentairsuppliesmustmeetthefollowingstandards:

● Type-1gaseousairasdenedin:CGACommoditySpecicationforAir,G-71(gradeD

or higher)

● Airsupplypressure:87psito125psi

● Airlinehoselength:5feetto300feet(maximumworkinghoselengthmustnotexceed

12 individual hose lengths)

● Airlineowrate:550liters/minute

● Approvedforuseattemperaturesabove-25°F(-31.7°C).

1. Turnontheindependentairsupply.

2. Connect the independent air supply coupling to the secondary supply hose (see

the PSS Series PneumaticAccessories Instructions for Use 3355853) and breathe

normally.

3. Closethecylindervalve(ifthewhistlesounds,silenceitbytakingseveralshortdeep

breaths or momentarily operating the lung demand regulator bypass button (Fig 2,

Item3)).

4. Ifanyairsupplyproblemsareencountered,proceedasfollows:

a. Openthecylindervalvetoreturntobreathingfromtheattachedcylinder.

b. Disconnecttheindependentairsupplycoupling.

c. Leavethehazardousareabytheshortestandsafestescaperoute,ifnecessary.

9.2 Cautions and limitations

D– Air-linerespiratorscanbeusedonlywhentherespiratorsaresuppliedwithrespirable

airmeetingtherequirementsofCGAG–7.1,GradeDorhigherquality.

E– UseonlythepressurerangesandhoselengthsspeciedintheUser’sInstructions.

I– Contains electrical parts that may cause an ignition in ammable or explosive

atmospheres.

J– Failuretoproperlyuseandmaintainthisproductcouldresultininjuryordeath.

M– Allapprovedrespiratorsshallbeselected,tted,used,andmaintainedinaccordance

withMSHA,OSHA,andotherapplicableregulations.

N– Neversubstitute,modify,add,oromitparts.Useonlyexactreplacementpartsinthe

congurationasspeciedbythemanufacturer.

O– RefertoUser’sInstructionsand/ormaintenancemanualsforinformationonuseand

maintenanceoftheserespirators.

S– Special orcritical User’s Instructions and/or specic use limitations apply.Refer to

User’sInstructionsbeforedonning.

S – Special or Critical Users Instructions

● Approvedforuseattemperaturesabove-25°F(-31.7°C).

● Whenusedasacombinationsupplied-airrespirator/self-containedbreathingapparatus

(SAR/SCBA),notmorethan20percentoftheairsupplycanbeusedduringentry.

● Duringsuppliedairuse,thecylindervalvemustremainclosed.Ifthesuppliedairfails,

openthecylindervalveandimmediatelyproceedtofreshair.

● Suppliedairsourcemustmeetthefollowingcriteria:pressure87psito125psi,airow

rateatleast550liters/minute.

Important Note: If it is decided to exit the working area with the airline disconnected

or, in an emergency, if the air supply fails, breathe normally and immediately

proceed as follows:

● Openthecylindervalve(counterclockwise)slowly,butfully,andbreathenormally.

● Disconnectthehoseoftheindependentairsupplyfromthemalecouplingoftheairline

hoseconnection.Breathenormallyandimmediatelyleavethehazardousareabythe

shortestandsafestroute.

Safety Warning: The remaining duration begins from the time of opening the

cylindervalveanddisconnectingtheindependentairsupply.Thetimerequiredto

allow the wearer to escape to a safe area must be within the remaining air capacity

(volume)ofthecylindertakingintoaccountthebreathingrateofthewearer.

10 Warranty information

UnlessotherwiseagreedbetweenDrägerandthecustomer,thefollowingshallapplyinthe

eventofdefectsoftheproductinmaterialorworkmanship:Thecustomershallcontactthe

companywhereheboughttheproduct(“Seller”).Thewarrantyconditionsagreedbetween

thecustomerandtheSellershallapply.Theproductmustbeusedinstrictaccordancewith

theInstructionsforUse.AnyusedisregardingtheInstructionsforUsemayvoidwarranty.

11 Contact details

Anyissueswiththeequipment,includingdamage,malfunction,orfailureofthebreathing

apparatus that may present a hazard to the user should be reported to the distributor

(DraegerSafety,Inc.).

Contactwiththecerticationorganizationmaybereachedat:

NIOSH,NPPTL–Phone1-412-386-4000

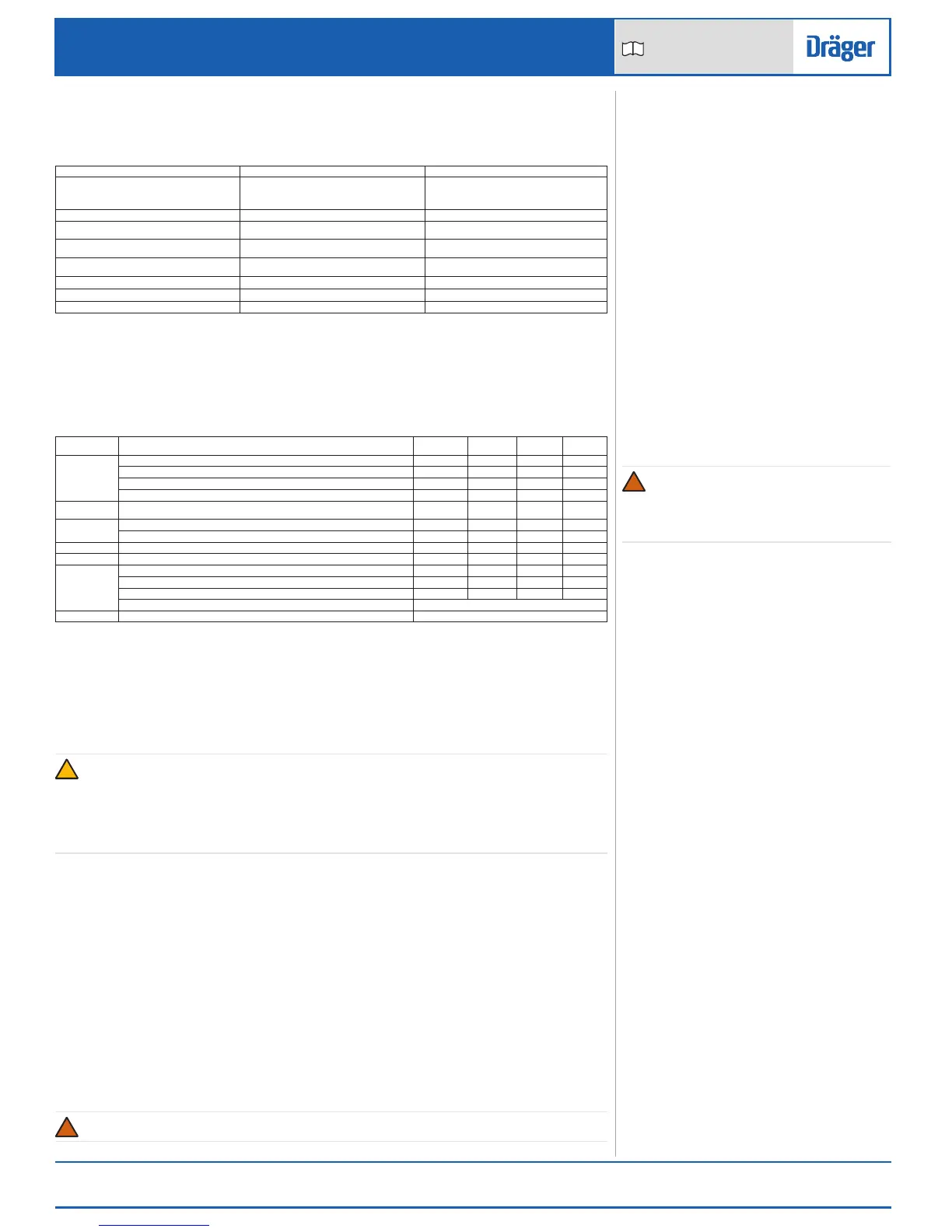

5 Maintenance

5.1 Maintenance table

Serviceandtestthebreathingapparatus,includingout-of-useapparatus,inaccordancewiththemaintenancetable.Recordallservicedetailsandtesting.ReferalsototheInstructionsfor

Useforthelungdemandregulator,facemaskandotherassociatedequipment.

Additionalinspectionandtestingmayberequiredinthecountryofusetoensurecompliancewithnationalregulations.

Component/

System

Task After

use

Every

month

Every

year

Every

10 years

Complete

apparatus

Cleananddisinfectifnecessary(seeSection5.2)

Visualinspection(seeSection3.5.1)

Functionaltesting(seeSection3.5.3)

Flowandstatictests(seeNote1)

Lungdemand

regulator

Cleananddisinfect(seeNote2andSection5.2)

First-stage

regulator

Medium-pressurecheck(seeNote1)

Inspectthesinteredlter(seeNote1andNote3)

Inspectthehigh-pressureconnectorO-ring(seeNote1andNote4)

Overhaul.ContactDrägerfortheRepairExchange(REX)service(seeNote5)

Cylinder Chargecylindertocorrectworkingpressure(seeSection5.3.1)

Checkchargedpressure(storedcylindersonly)

Checktestdateofcylinder(carboncompositecylindersover15yearsoldmustberetired)

Recertication Accordingtonationalregulationsinthecountryofuse

Cylindervalve Overhaul Atthetimeofcylinderrecertication

Notes

Drägerrecommendations.

1 These maintenancetasksmayonly be carriedoutbyDräger or trainedservicepersonnel.Details of thetestsarecontained in theTechnicalManualwhich is issuedtoservice

personnelthathaveattendedarelevantDrägermaintenancecourse.

2 LightlylubricatetheO-ringofthelungdemandregulatorasrequired(recommendedlubricantisDowCorning111ValveLubricantandSealant).Productsotherthantherecommended

lubricantarenottestedandmaydam-agetheequipment.

3 Replacethesinteredlterifadropinrst-stageregulatorperformanceisobservedduringaowcheckorifitisvisiblydamaged.

4 Replacethehigh-pressureconnectorO-ringifitisfoundtoleakduringfunctionaltestingoriftheO-ringisvisiblydamaged.

5 Wherethebreathingapparatusissubjectedtoahighlevelofuse(intrainingestablishmentsetc.),reducetheoverhaulperiodfortherst-stageregulator.Inthesecircumstances,

Drägerrecommendthattheoverhaulfrequency should be lessthan5,000applicationsofuse.An applicationofuseisdenedasasingleuse of the fullyassembledbreathing

apparatus,wheretheuserbreathesfromtheaircylinder.Itdoesnotincludesystempressurizationforpre-operationalchecks.

5.2 Cleaning and disinfecting

CAUTION

CleaningagentsanddisinfectantslistedbelowarenotmanufacturedbyDrägerandhavebeenreviewedonlyforcompatibilitywhenusedtocleanordisinfectthesubjectDräger

product(s).Readandcomplywithallinstructionsforuseprovidedbythemanufacturersofsuchagentsanddisinfectants.Drägerexpresslydisclaimsallresponsibilityforany

damage,personalinjuryorlossresultingfromtheuseofsuchagentsordisinfectants.

Donotexceed86°F(30°C)forwashing,disinfectingandrinsingsolutions.Donotexceed140°F(60°C)fordrying,andremovecomponentsfromthedryingfacilityimmediately

whendry.Dryingtimeinaheateddryermustnotexceed30minutes.

Donotimmersepneumaticorelectroniccomponentsincleaningsolutionsorwater.

Ifwateristrappedandthenfreezesinsidethepneumaticsystemofthebreathingapparatus(suchasthelungdemandregulator),operationwillbeimpaired.Preventanyliquid

fromentering,andthoroughlydrythebreathingapparatusaftercleaningtopreventthisfromoccurring.

Referalsototheinstructionsforthelungdemandregulator,facemaskandotherassociatedequipment.

5.2.1 Manual cleaning of the breathing apparatus (USA)

Cleaning and disinfecting materials:

● Cleaningagent–1008GreenLiquidHandDishWash

● Disinfectingagent–800Spur-TexDisinfectantCleaner-Deodorant(concentration:1.6%(2ozpergallon))

● Useonlycleanlint-freecloths.

1. Preparecleaningsolutionaspermanufacturer’sinstructions.Cleanthebreathingapparatusmanuallyusingaclothmoistenedwithcleaningsolutiontoremoveexcessdirt.

2. Preparedisinfectingsolutionaspermanufacturer’sinstructions.Applytoallinternalandexternalsurfaces,ensuringthatallsurfacesremainvisiblywetfor15minutes.

3. Rinseallcomponentsthoroughlywithcleanwatertoremoveallcleaninganddisinfectingagents.

4. Dryallcomponentsusingadrycloth,inaheateddryerorinair.

5. ContactservicepersonnelorDrägerifdisassemblyofpneumaticorelectroniccomponentsisrequired.

5.2.2 Manual cleaning of the breathing apparatus (Canada)

Cleaning and disinfecting materials:

● Cleaningagent–mildsoapsolution

● Disinfectingagent–NeutralDisinfectantCleaner(concentration:0.5%(0.5ozpergallonor15mlper3.785liters))

● Useonlycleanlint-freecloths.

1. Preparecleaningsolutionaspermanufacturer’sinstructions.Cleanthebreathingapparatusmanuallyusingaclothmoistenedwithcleaningsolutiontoremoveexcessdirt.

2. Preparedisinfectingsolutionaspermanufacturer’sinstructions.Applytoallinternalandexternalsurfaces,ensuringthatallsurfacesremainvisiblywetfor10minutes.

3. Rinseallcomponentsthoroughlywithcleanwatertoremoveallcleaninganddisinfectingagents.

4. Dryallcomponentsusingadrycloth,inaheateddryerorinair.

5. ContactservicepersonnelorDrägerifdisassemblyofpneumaticorelectroniccomponentsisrequired.

5.3 Maintenance work

5.3.1 Air cylinder charging

!

WARNING

Airqualityforcompressed-aircylindersmustconformtotheminimumgraderequirementsforType1gaseousairasdenedintheCGACommoditySpecicationforAir,G-7.1

(GradeDorhigherquality).

Refertotheinstructionssuppliedwiththecylinderandthechargingapparatusforrechargingacompressed-aircylinder.

Loading...

Loading...