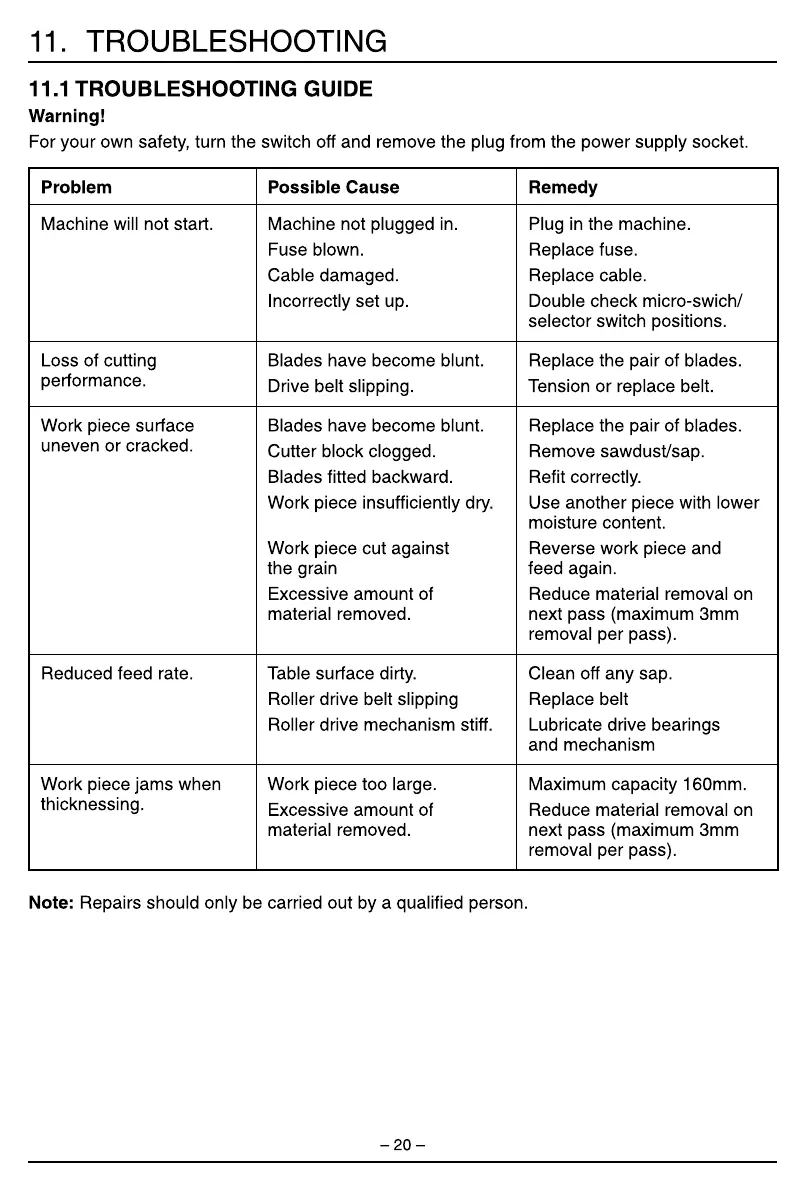

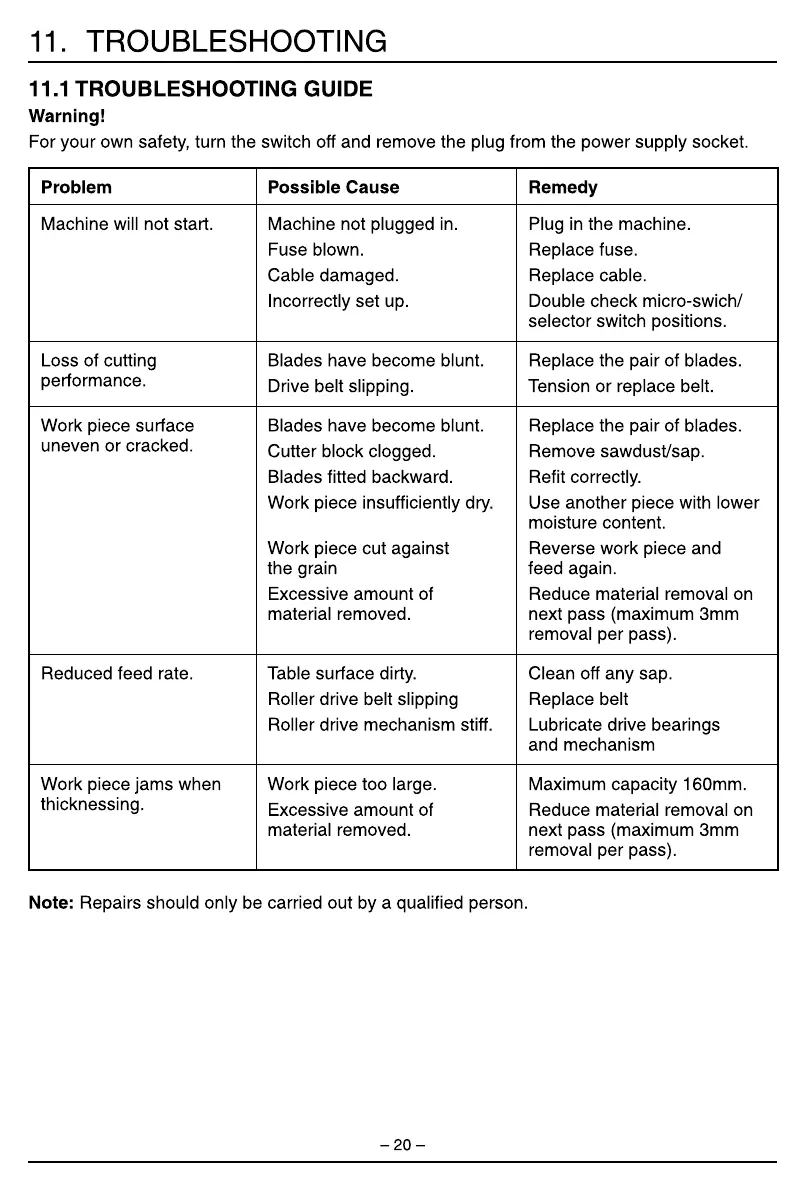

11.1 TROUBLESHOOTING GUIDE

Warning!

For your own safety, turn the switch off and remove the plug from the power supply socket.

Problem Possible Cause Remedy

Machine will not start. Machine not plugged in.

Fuse blown.

Cable damaged.

Incorrectly set up.

Plug in the machine.

Replace fuse.

Replace cable.

Double check micro-swich/

selector switch positions.

Loss of cutting

performance.

Blades have become blunt.

Drive belt slipping.

Replace the pair of blades.

Tension or replace belt.

Work piece surface

uneven or cracked.

Blades have become blunt.

Cutter block clogged.

Blades fitted backward.

Work piece insufficiently dry.

Work piece cut against

the grain

Excessive amount of

material removed.

Replace the pair of blades.

Remove sawdust/sap.

Refit correctly.

Use another piece with lower

moisture content.

Reverse work piece and

feed again.

Reduce material removal on

next pass (maximum 3mm

removal per pass).

Reduced feed rate. Table surface dirty.

Roller drive belt slipping

Roller drive mechanism stiff.

Clean off any sap.

Replace belt

Lubricate drive bearings

and mechanism

Work piece jams when

thicknessing.

Work piece too large.

Excessive amount of

material removed.

Maximum capacity 160mm.

Reduce material removal on

next pass (maximum 3mm

removal per pass).

Note: Repairs should only be carried out by a qualified person.

Loading...

Loading...