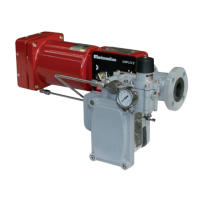

What to do if there is a short in Dresser Valve Positioners force coil?

- SSamuel WebsterAug 4, 2025

If the Dresser Valve Positioners' force coil has a short, replace it. Use an ohmmeter to check the coil's resistance; it should show very high resistance (practically infinite). If the ohmmeter indicates another value, replace the coil.