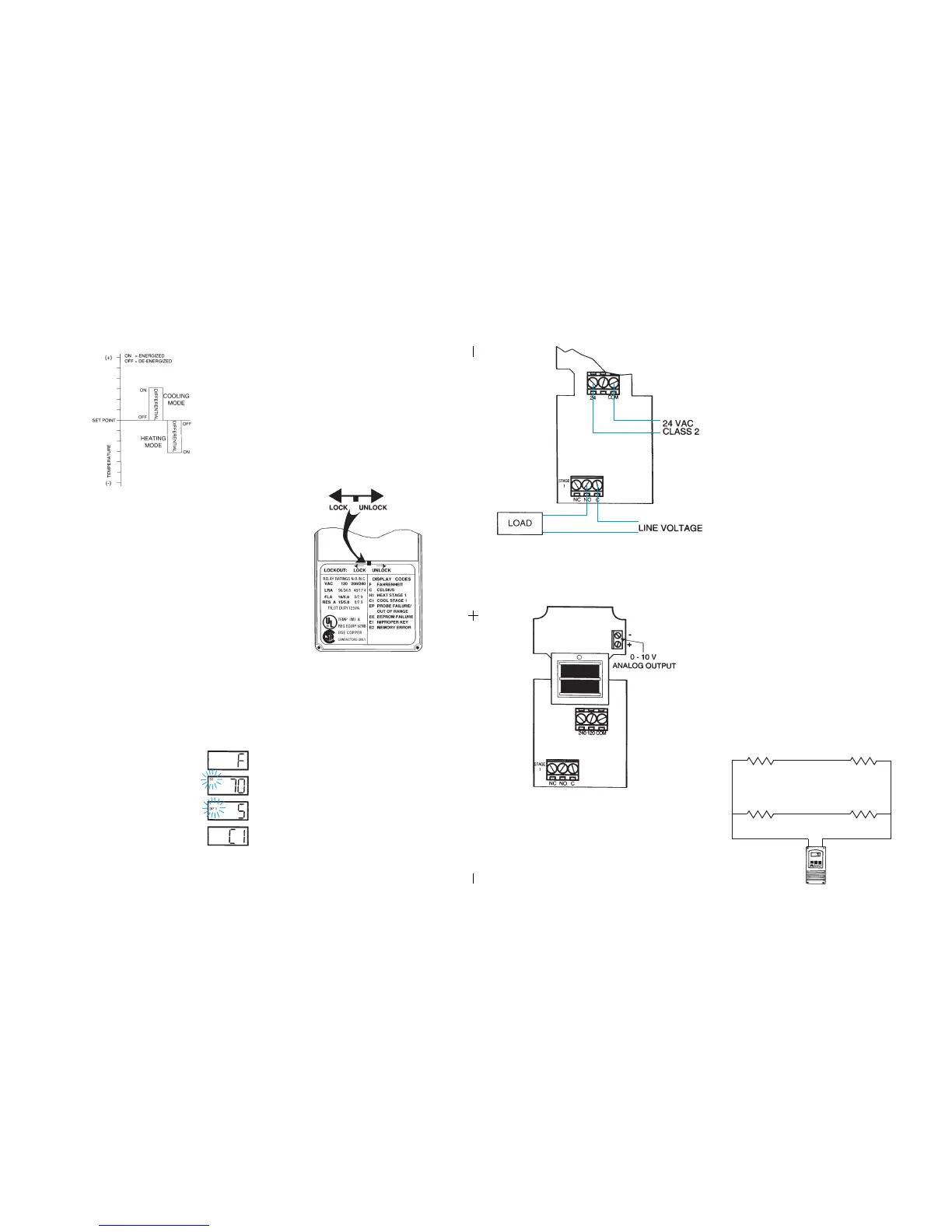

Figure 7: Typical Wiring Diagram for 24 VAC Power Input and

Line Voltage Switching.

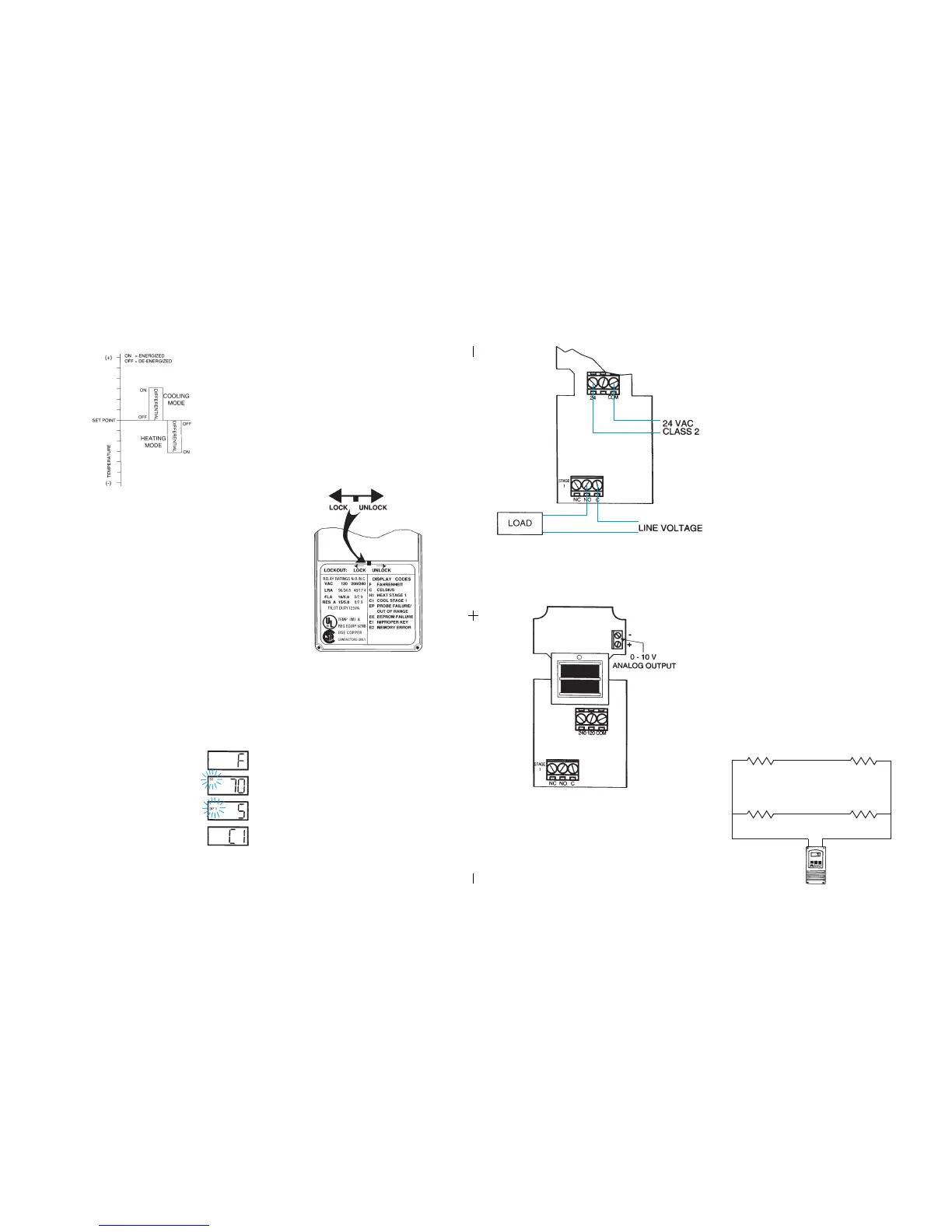

Figure 8: 0-10 V Analog Output Located on Power (Lower) Circuit Board.

FIELD REPAIRS

Field calibrating or repairs to the ETC control must not be attempted. Sensors

and replacement controls are available through Ranco wholesalers.

SENSOR MOUNTING

For space sensing, mount the sensor where it will be unaffected

by heat/cool discharge or radiated heat sources. Spot sensing

requires the sensor to be in good contact with the surface being

sensed. The sensor can be inserted in a bulb well for immersion

sensing.

TEMPERATURE AVERAGING

ETC CONTROL

EXTENDING SENSOR

CAUTION: Sensor wiring splices may be made external from the

control. DO NOT attempt to unsolder the sensor at the control

circuit board!

CAUTION: Disconnect power to control before wiring to avoid

possible electrical shock or damage to the controller.

Additional cable can be spliced to the sensor cable to increase the

length beyond the standard 8 feet. It can be extended up to 400

feet. The cable should be at least 22 AWG or larger to keep

additional resistance to a minimum.

All splices and wire lengths added to the sensor cable should be

made according to acceptable wiring practices and should con-

form to the National Electrical Code and local regulations. Use

copper conductors only. Shielded cable is not required.

Checkout Procedure

1. Before applying power, make sure installation and wiring

connections are correct.

2. Apply power to the control and observe one or more cycles

of operation.

3. If performance indicates a problem, check sensor

resistance to determine if sensor or control is at fault.

4. To check sensor resistance, disconnect sensor and

measure the resistance across the leads while measuring

temperature at the sensor.

(4) Sensors wired in series/parallel for temperature averaging.

SENSOR

SENSOR

5

Step 1- To start programming, press the SET key once to access the

Fahrenheit/Celsius mode. The display will show the current

status, either F for degrees Fahrenheit or C for degrees Celsius.

Then press either the up or down arrow key to toggle

between the F or C designation.

Step 4- Press the SET key again to access the cooling or heating mode.

The LCD will display the current mode, either C1 for cooling or

H1 for heating. Then press either the up or down key to

toggle between the C1 or H1 designation. Press the SET key

once more and programming is complete.

Step 3- Press the SET key again to access the differential. The LCD will

display the current differential and the DIF 1 annunciator will be

blinking on and off to indicate that the control is in the differential

mode. Then press either the up key to increase or the down

key to decrease the differential to the desired setting.

Step 2- Press the SET key again to access the setpoint. The LCD

will display the current setpoint and the S1 annunciator will be

blinking on and off to indicate that the control is in the setpoint

mode. Then press either the up key to increase or the down

key to decrease the setpoint to the desired temperature.

Step Annunciator Description Display

1 F or C Fahrenheit or Celsius Scale

2 S1 (blinking) Setpoint Temperature

3 DIF 1 (blinking) Differential Temperature

4 C1/H1 Cooling or Heating Mode

Figure 1: Setpoint and Differential Settings. Diagram indicates relay

on and off points in either the heating or cooling modes.

TROUBLESHOOTING ERROR MESSAGES

All control settings are retained in non-volatile memory if power to ETC is

interrupted for any reason. Re-programming is not necessary after power

outages or disconnects unless different control settings are required.

Lockout Switch

The ETC is provided with a lockout switch to prevent tampering by unautho-

rized personnel. When placed in the LOCK position, the keypad is disabled

and no changes to the settings can be made. When placed in the UNLOCK

position, the keypad will function normally.

Display Messages

Programming Steps and Display

The ETC can be programmed in four simple steps using the LCD display and

the three keys on the face of the control.

NOTE: The ETC will automatically end programming if no keys are

depressed for a period of thirty seconds. Any settings that have been input

to the control will be accepted at that point.

To access the lockout switch, disconnect the power supply and open the

control. The switch is located on the inside cover about 2 inches above the

bottom. (see Figure 2). To disable the keypad, slide the switch to the left

LOCK position. To enable the keypad, slide the switch to the right

UNLOCK position. All ETC controls are shipped with this switch in the

UNLOCK position.

Figure 2: Lockout Switch

EP - Appears when the probe is open, shorted or sensing a tempera-

ture that is out of range.

To correct: Check to see if the sensed temperature is out of

range. If not, check for probe damage by comparing it to a

known ambient temperature between -30°F and 220°F. Replace

the probe if necessary.

EE - Appears if the EEPROM data has been corrupted.

To correct: This condition cannot be field repaired. Replace

the control.

CL - Appears if calibration mode has been entered.

To correct: Remove power to the control for at least five

seconds. Reapply power. If the CL message still appears,

replace the control.

➡

➡

➡

➡

➡

➡

➡

➡

E2 - Appears if the control settings are not properly stored in memory.

To correct: Check all settings and correct if necessary.

➡

➡

E1 - Appears when either the up or down key is pressed when

not in the programming mode.

To correct: If the E1 message appears even when no keys are

being pressed, replace the control.

2

SENSOR SENSOR

Figure 9:

Loading...

Loading...