180

In the event of a breakdown

08

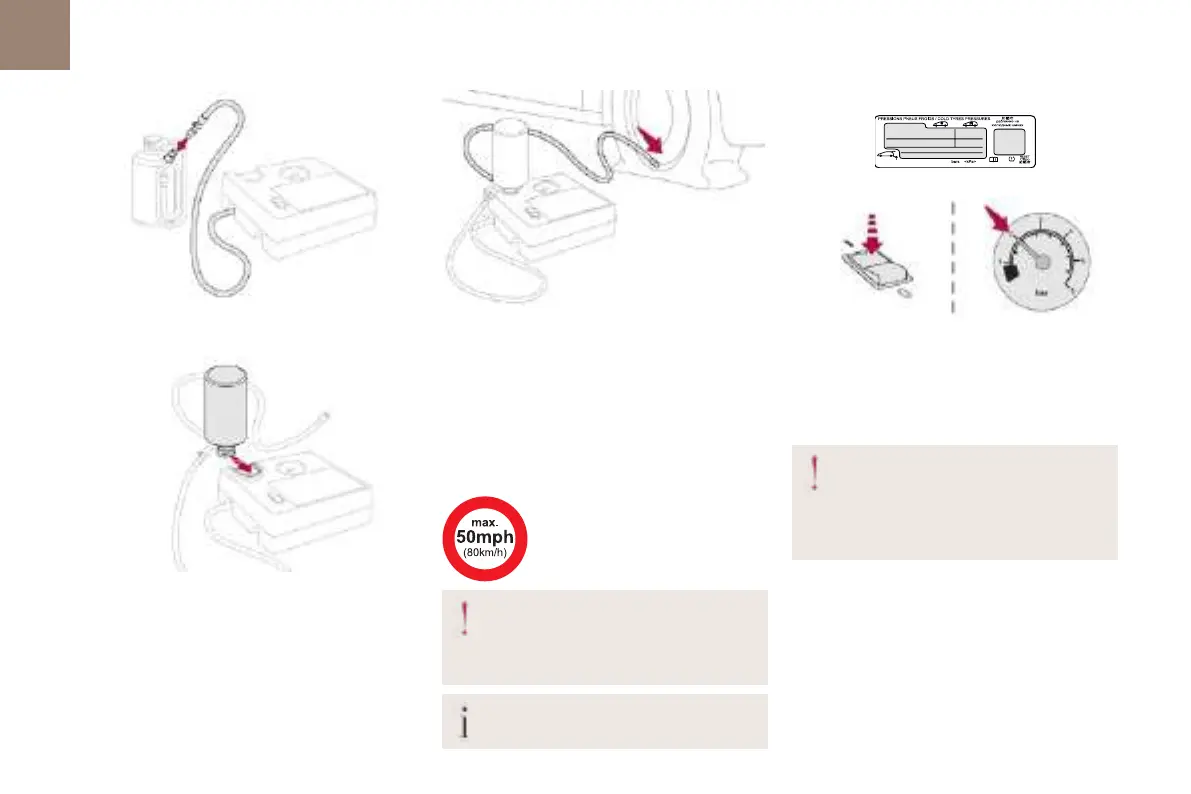

► Connect the pipe from the compressor to the

bottle of sealant.

► Turn the bottle of sealant over and secure it in

the notch provided on the compressor.

► Remove the valve cap from the tyre to be

repaired, and place it in a clean area.

► Connect the hose from the bottle of sealant

to the valve of the tyre to be repaired and tighten

firmly.

► Check that the compressor switch is in

position"O".

► Fully uncoil the electric cable stowed under

the compressor.

► Connect the compressor's electric plug to the

vehicle's 12V socket.

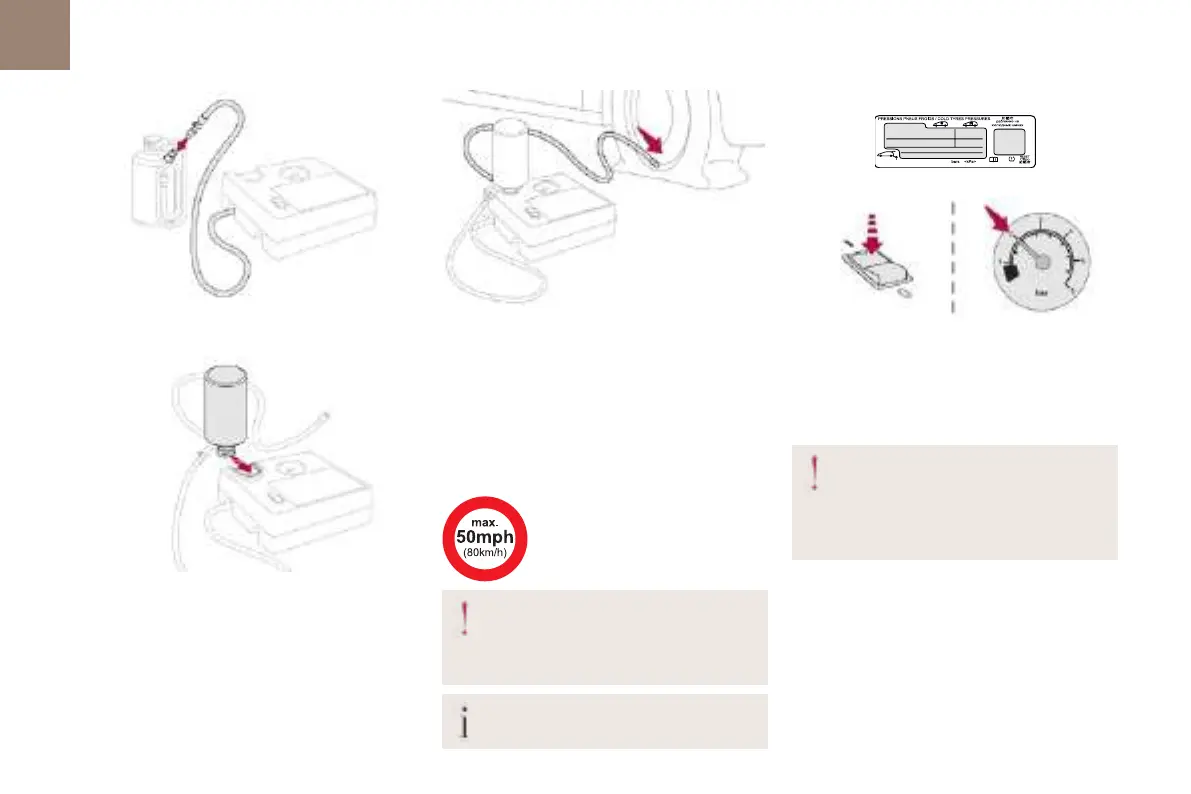

► Affix the speed limit sticker.

The speed limit sticker must be secured to

the interior of the vehicle in the area close

to the driver, to remind the driver that a wheel

is in temporary use.

The tyre inflation pressures are given on

this label.

► Switch on the ignition.

► Switch on the compressor by moving the

switch to position "I" until the tyre pressure

reaches 2 bar. The sealant product is injected

under pressure into the tyre; do not disconnect

the pipe from the valve during this operation (risk

of blowback).

If after approximately 7 minutes, the

pressure of 2 bar is not reached, this

indicates that the tyre is not repairable;

contact a dealer or a qualified workshop for

assistance.

► Move the switch to position "O".

► Disconnect the compressor's electric plug

from the vehicle's 12V socket.

► Refit the cap on the valve.

► Remove the kit.

► Remove and store the bottle of sealant.

Loading...

Loading...