4

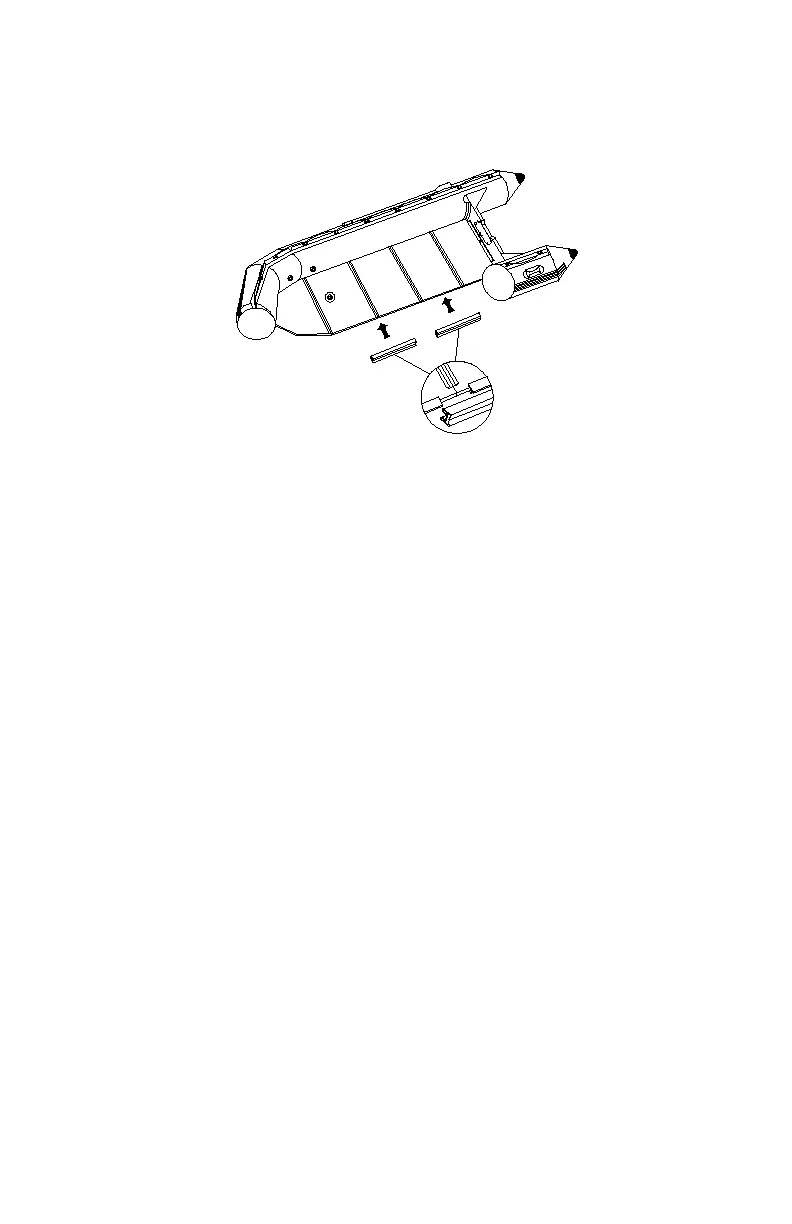

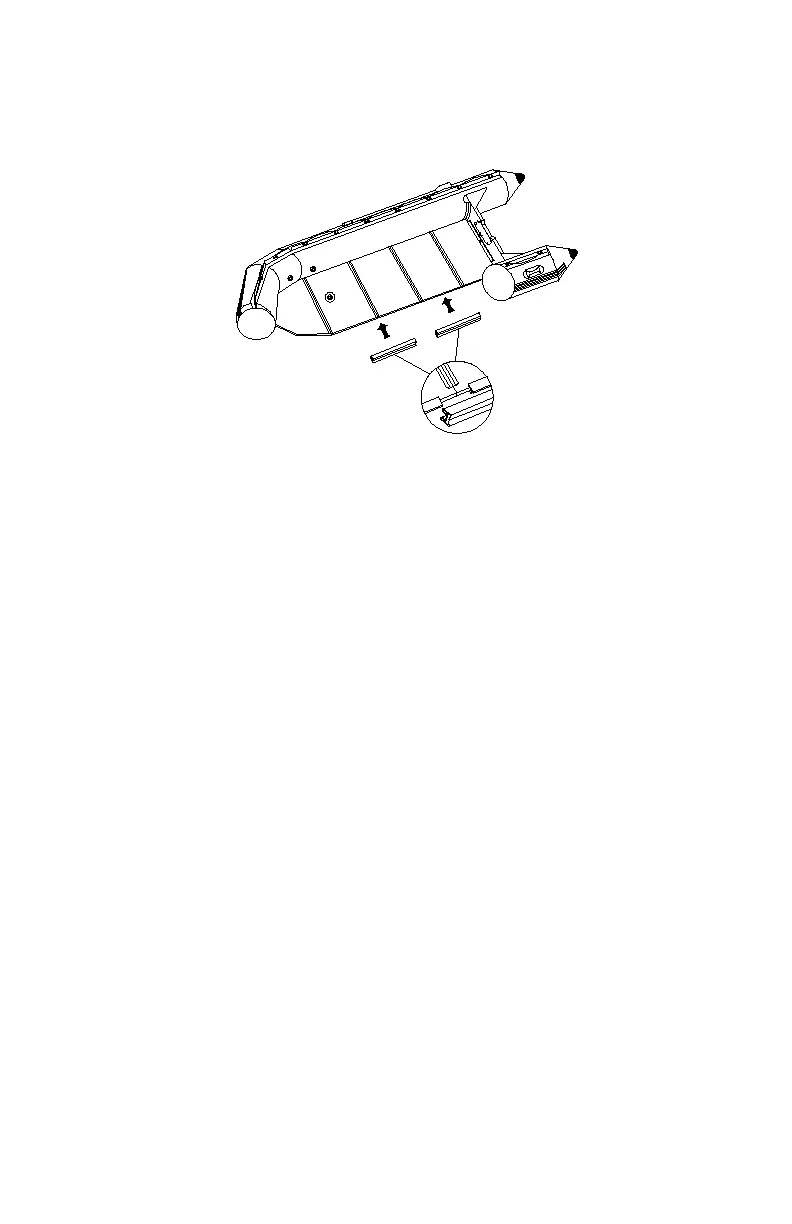

Stringers

Insert aluminum stringers into side edges of the floorboards making sure that

the stringers overlap each board to ensure floorboards are straight and rigid.

Air Floor Model:

a. Insert aluminum floor brace/slat into the space provide on the

bottom of the air floor (located towards the front of air floor). The

brace ensures optimal hull shape is maintained at higher speeds.

b. Put the air floor in boat and flatten. Pay special attention to insert

the edge of the air floor between the floor and inside of the tube.

c. Be sure that the air floor access hole to the keel’s air valve is

aligned properly.

d. Inflate the air floor to a minimum of 6psi or maximum of 8psi.

4. Aluminum Seat

Inflate chambers to 90% of their recommended pressure and slide your

aluminum seat onto the attachments located on the tubes.

5. Finish inflation

a. Inflate side tubes first, then the bow tube(s) to ensure equal

pressure in all tubes.

b. Inflate hull air chambers to 100%, or 3.6psi.

c. Inflate keel between 1.5 and 2psi (max. capacity 2psi). For optimal

performance inflate keel to 80% of maximum capacity.

6. Deflation

Remove the outer valve caps to expose the yellow plastic stem on the inner

valve. Press the yellow plastic stem in to release air pressure, and turn it to

lock the valve in the open position. Deflate each hull chamber 50-75%

before completely deflating any of the air chambers.

NOTICE: Do not deflate one chamber fully while others are fully inflated.

Improper deflation could damage the bulkheads of your boat.

Remove the floorboards by first removing the aluminum side stringers.

Loading...

Loading...