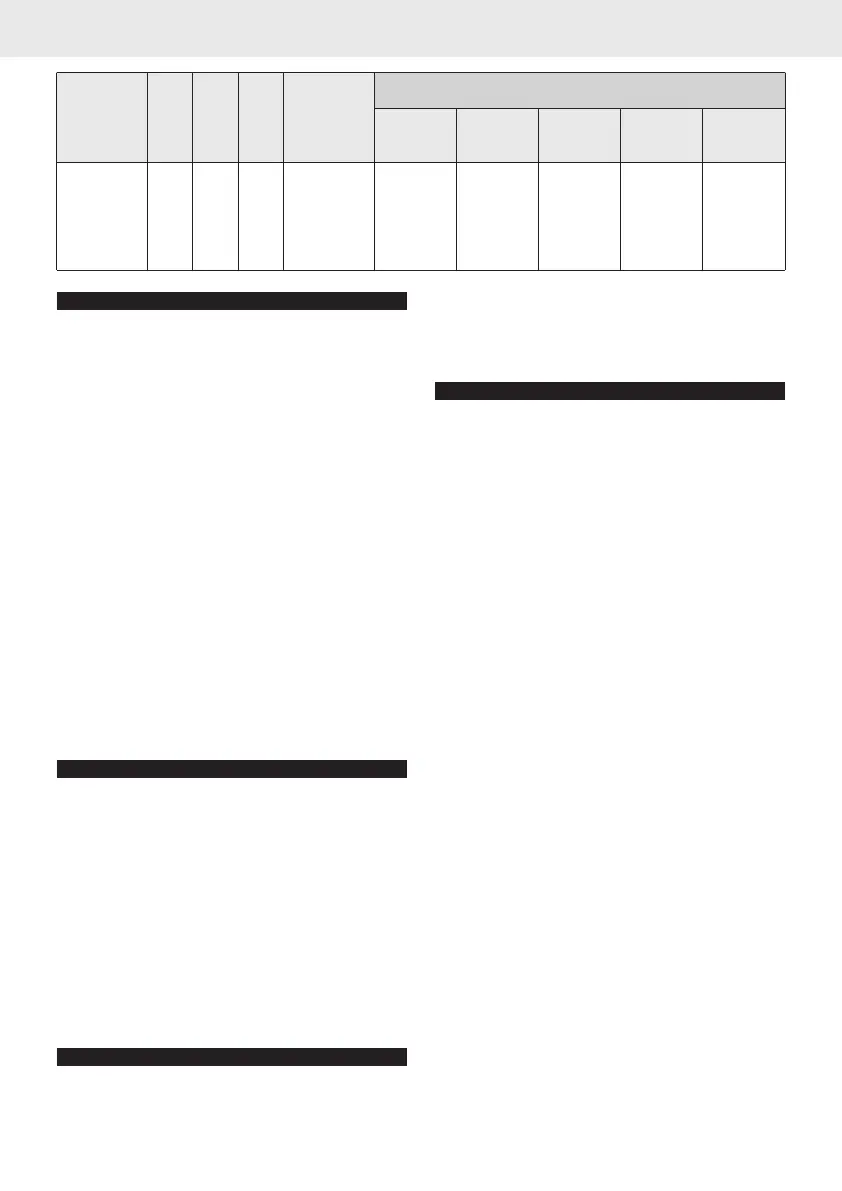

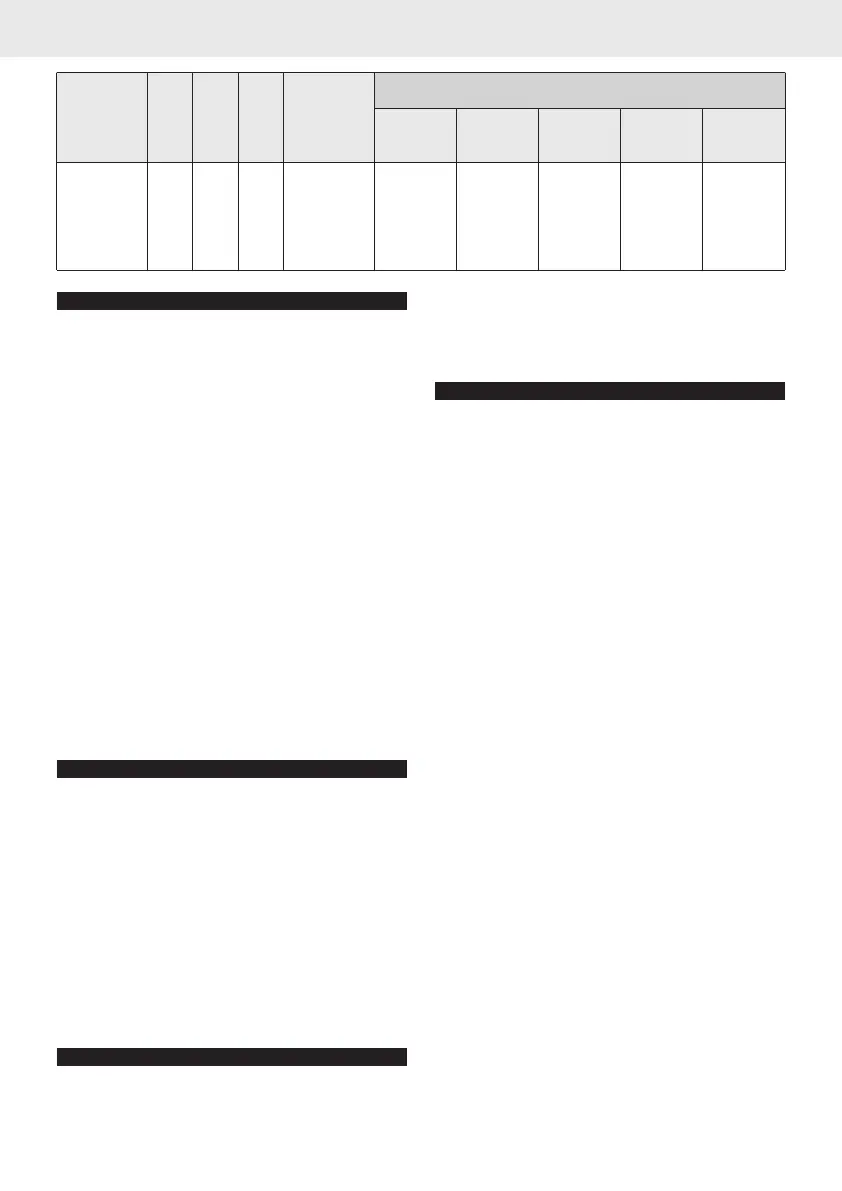

LT5 300 5 3,5 0,5

LT8 400 7,5 5,6 1

LT12 500 9,5 8,4 1,5

LT16 600 12 11,2 2

LT20 900 19 14 2,5

1050 700 525 420 350

1680 1120 840 672 560

2520 1680 1260 1008 840

3360 2240 1680 1344 1120

4200 2800 2100 1680 1400

TECHNICAL DATA

• Flow Rate 1000 l/h

• Minimum/Maximum Pressure 1 ÷ 8 bar

• Feed Water Min./Max. Temperature 4°C ÷ 25°C

Figure 1 LEGEND

A Water Inlet E Pressure Relief Hose

B Water Outlet F Regeneration Hose

C Water Inlet Tap G Cover Knob

D Water Outlet Tap I Check Valve

This leaflet is an integral part of the product.

Please read the warnings provided carefully as

these provide important information concerning

the safe installation, use and servicing of this pro-

duct. This water softener is intended to be used to

soften cold drinking water only, any other use is

considered improper and as such unreasonable.

WARNING: use only sodium chloride NaCl in lar-

ge grains (kitchen salt) for regeneration. The use

of any other chemical substances or products is

strictly forbidden.

The resins in the water softener are needed

for this to work properly: please do not throw

them away.

INSTALLATION

• After removing the packaging, make sure that

the water softener isn’t damaged. Keep the

packaging materials (plastic bags, cardboard

box etc...) out of the reach of children as they

can be dangerous. The water softener should be

installed in full observance of the current laws,

following the manufacturer’s instructions and by

experts. If installed incorrectly, the equipment

may cause injuries to people and animals and

damage to property, in which case the manu-

facturer cannot be held liable.

• Install the water softener in rooms where the

temperature is between a minimum of 5 °C and

a maximum of 30 °C(Centigrade).

CONNECTION TO THE WATER MAINS (figure 1)

• The user must install a tap between the water

mains and the water softener so that the water

can be turned off in an emergency, plus a check

valve to avoid any pressure returns.

• Connect the water inlet and outlet hoses to the

water softener and make sure that these are ti-

ghtened properly.

• Place the drain hose directly in a drain.

COMMISSIONING

• RINSING OF RESINS (figure 2)

Place the outlet hose in a drain.

Turn the taps’ levers to the left and open the

water inlet; let the water flow until it is clear,

then stop the inlet water and connect the outlet

hose to the machine to be supplied.

• ROUTINE REGENERATION (figure 3)

• position B

1) Place the depression hose in a bucket. Turn the

taps’ levers to the right and wait for the pres-

sure to drop. Remove the cover by unscrewing

the knob and then add the salt in the amount

indicated to suit the model (see table 1).

WARNING: Remove any salt from the seal on the

cover.

• position C

2) Return the cover and tighten the knob securely,

then move the inlet tap lever to the left.

WARNING: Remove any salt from the top of the

water softener.

3) Let the salty water flow from the drain hose

until the water is soft (about 40 minutes).

• position A

4) Return the water softener to normal working

conditions by turning the outlet tap lever to the

left.

5) Regeneration completed.

WARNING: the equipment connected to the

water softener is not supplied during regene-

ration.

To ensure the efficiency of the water softener at all

times, we recommend routine regeneration to suit

the use made of the water softener and the hard-

ness of the water used.

Please use the sheet printed on the last page to

keep a note of the dates when regeneration is

carried out.

4 Instruction leaflet and warnings for water softeners

ENGLISH Water Softener LT

20°f 30°f 40°f 50°f 60°f

11°d 16°d 22°d 28°d 33°d

200 ppm CaCO

3

300 ppm CaCO

3

400 ppm CaCO

3

500 ppm CaCO

3

600 ppm CaCO

3

LITERS OF WATER SOFTENED DEPENDING ON HARDNESS

WEI-

GHT

[kg]

RESINS

[l]

SALT/REG.

[kg]

h

[mm]

MODEL

Loading...

Loading...